Boston Materials (Billerica, Mass., U.S.) was formed in 2016 by Anvesh Gurijala, Michael Segal and Dr. Randall Erb as a spin-out from Northeastern University (Boston, Mass., U.S.) to commercialize a patented magnetic alignment process that enables milled carbon fibers to be oriented vertically into a sheet using a roll-to-roll process. “These film-like materials look like velour or velvet thanks to the vertical fibers,” says Boston Materials chief commercial officer, Kedar Murthy. With a length of 0.05 to 0.2 millimeters, milled carbon fibers are an interesting solution, providing macro-scale benefits without the production, cost and health/safety issues of nanomaterials. They also provide an outlet for the growing amount of available reclaimed/recycled carbon fiber, which costs significantly less than virgin fiber and imparts desperately needed circularity for the composites market.

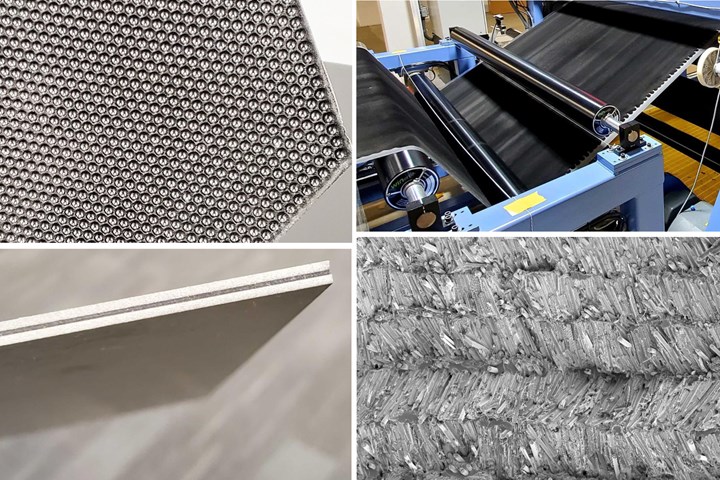

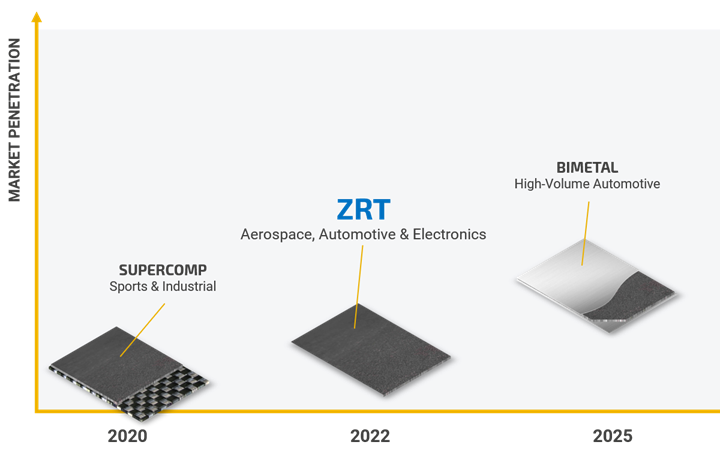

Boston Materials has now scaled their process to produce 800,000 square meters of 60-inch-wide material per year for a growing family of products:

- SUPERCOMP – Z-axis carbon fiber film laminated to standard woven

and UD prepregs and dry reinforcements, launched in 2019 and used in tooling, snowboards, skis, reflector dishes and industrial applications; - ZRT – thermoplastic films and thermoset prepregs for thermal/electrical conductivity and local reinforcement, launched in 2020 and being evaluated as part of 2-year development cycles for consumer electronics and automotive applications;

- BIMETAL – Z-axis carbon fiber film sandwiched between sheet metal skins offering performance parity with monolithic sheet metal at up to 50% less weight, aimed at stamp-formed sheet metal parts in automotive applications.

Aerospace is also a key target, including integration of lightning strike protection (LSP), increased delamination resistance and vibration damping, and local reinforcement, the latter having the ability, for example, to boost fastener pull-out strength by 50%. However, aerospace qualification is typically a longer process, and thus, non-aerospace targets are being commercialized first.

Long history of z-fiber technologies

SAERfoam features glass fibers inserted through the core. Photo Credit: SAERTEX

The idea of using z-axis fibers to improve interlaminar shear strength(ILSS),out-of-plane stiffness (transverse modulus), impact resistance and bonding in composites is not new. For decades, boatbuilders have used milled glass fiber in core bonding putty to increase bond strength, the milled fibers providing a crack-stop mechanism by sticking halfway into the putty and halfway into the open cells of the foam core. SAERTEX (Saerbeck, Germany) went a step further, inserting cut glass fiber through the foam core of its SAERfoam products to tie cored laminate faceskins together once infused with resin.

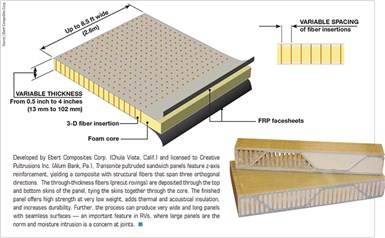

Creative Pultrusions Transonite pultruded sandwich panels feature z-axis reinforcement.

Z-pinning, commercialized by Aztec’s (Waltham, Mass., U.S.) cured Z-Fiber product in the 1980s, has since been studied and developed by numerous organizations including aeroengine manufacturers, Airbus and the U.S. military. The technique inserts pre-cured carbon fiber reinforced polymer (CFRP) pins, typically 1-millimeter in diameter, into uncured prepreg layups. However, pin insertion is an additional step, and a method to insert these cost-effectively for z-axis fiber content more toward 30-50% was never demonstrated.

3D weaving was developed to achieve the same goal. It is used by Albany Engineered Composites (Rochester, NH, U.S.) to produce the complex preforms that are converted via resin transform molding (RTM) into CFRP fan blades for the LEAP aeroengine. Though it is effective, 3D weaving remains, typically, neither a fast nor inexpensive process to provide z-axis reinforcement.

On the opposite end of the geometric scale is the NanoStitch technologydeveloped by N12 Technologies, now acquired by NAWA Technologies (Aix-en-Provence, France), which uses vertically aligned carbon nanotubes (CNTs) in the interlaminar region between laminate plies, boosting ILSS by 10-30% (see “The end of delamination?”). Even though N12’s broad goods promised improved properties with a drop-in solution for current composite processes, cost and scalability were issues due to the nascent technology of growing vertically aligned CNTs.

Drop-in solution with scalability

“3D weaving, z-pinning and stitching all require additional steps and labor,” notes Murthy. “We wanted a material that could be easily integrated as a ply into processes and materials already in use. Our ZRT products handle like an adhesive film or unidirectional prepreg yet provide stiffness and conductivity in the z-direction, leveraging the properties of the resulting composites in a new direction.”

Lamination process to make SUPERCOMP products combining ZRT film and continuous fiber reinforcement. Photo credit: Boston Materials

“Another difference in our materials is scalability,” explains Boston Materials CEO Anvesh Gurijala. “We are using a 60-inch-wide, roll-to-roll process that is similar to papermaking. The milled fibers are dispersed in water, metered onto a PET carrier film and then subjected to a magnetic field to align the fibers in the z-axis.” He notes that carbon fiber is not magnetic, so this alignment is the trick. The water is then evaporated, leaving the dry ZRT material on top of the carrier. So, this is not growing CNTs and is much more cost-effective. There is a lot less technical risk versus nanomaterials and no hazardous chemicals, solvents or particles — it is an eco-friendly process.”

The ZRT roll goods are also process-friendly. “They can be used dry or prepregged,” says Murthy. “You can slit the product into tapes and use it for winding or dry preforms for RTM. Our materials are readily integrated into the tape-laying process; no secondary steps are needed. It is easy to remove the ZRT material from the carrier film and there is no release of nanofibers or milled fibers.” ZRT materials also provide a high surface area resulting in good bonding to coatings or paint. “Because we are using recycled carbon fiber,” notes Gurijala, “we can be cost-competitive with continuous virgin fiber.”

There is actually a cost benefit to using SUPERCOMP and ZRT materials, says Gurijala. “By adding plies of ZRT materials, we can retain key in-plane properties of a conventional CFRP laminate while displacing up to 50% of the continuous fiber. By designing the laminate with ZRT materials and standard CFRP materials, we can maintain in-plane performance and increase out-of-plane properties while reducing the overall number of plies needed by as much as 50%. So, we are offering an economical and drop-in solution, but also augmented functionality.”

Additional functionalities

By orienting carbon fibers out-of-plane, Boston Materials overcomes composites’ traditional limitations in conductivity through the laminate thickness. “We are demonstrating thermal and electrical conductivity that competes with aluminum,” says Gurijala. “We are reaching performance parity with nanofibers, nickel veils and expanded metal foils for EMI and lightning strike protection, but with improved cost and processability. For example, because our products are carbon fiber and not metal, they do not require insulation to prevent galvanic corrosion with carbon fiber laminates. There is also no corrosion in-service from exposure to moisture, chemicals, etc.”

Lightning strike protection

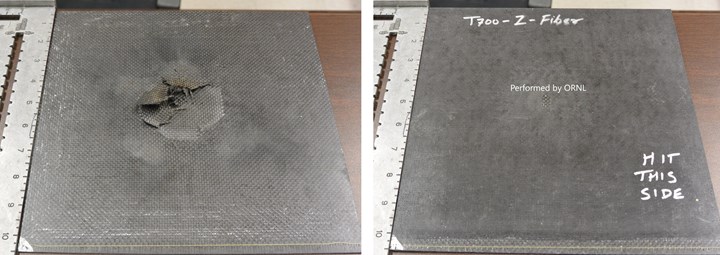

Initial lightning strike tests have shown the ability of ZRT films to provide effective LSP for CFRP panels. The photos below show, on the left, a reference laminate comprising five plies of woven carbon fiber in an epoxy matrix, and that same laminate on the right, but with a ZRT surfacing film. The testing was performed by Dr. Vipin Kumar, who is a lightning strike damage expert of CFRPs from Oak Ridge National Laboratory (Knoxville, TN). “The reduction in damage is very clear,” says Dr. Kumar. “This ZRT was made with PAN fibers but we expect even better results with pitch fiber due to its higher conductivity.” Boston Materials has an award pending from the U.S. Air Force to further develop this approach for conventional aircraft and upcoming eVTOL vehicles.

Fastener pull-out

ZRT plies used within a CFRP laminate have been used to help resist delamination between plies and reduce debonding of metal fasteners. Eclipse Composites Engineering (Salt Lake City, Utah, U.S.) was working to improve a component where the primary failure was debonding of metal lugs due to shear and transverse tension. “We worked with Eclipse to integrate our SUPERCOMP 1015 PW Dry product — which is ZRT film combined with dry plain weave fabric — between each layer of woven 3K carbon fiber fabric in the laminate,” explains Murthy.

“During pull-out tests made with standard laminates, the metal lugs completely debonded, while the laminates made with the SUPERCOMP plies retained the metal lugs. When testing to failure, Eclipse Composites measured at least 50% higher pull-out strength before failure and the failure was gradual, not catastrophic. There were even a few cases where the steel bolt that threads into the metal lug failed before the lug was pulled out.”

Qualification test part made with a SUPERCOMP PW Dry material by Boston Materials demonstrated a 50% increase in pull-out strength of metal lugs (green arrows) before failure. Photo credit: Eclipse Composites Engineering

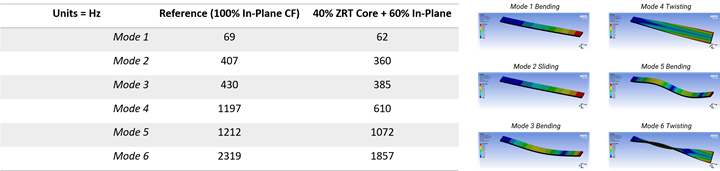

ZRT materials also absorb vibration energy via shear without sacrificing bending stiffness. “This is a mechanism that is unique to z-axis carbon fiber,” says Gurijala. “Incorporating plies of ZRT into a composite structure can reduce the natural frequency in every mode of vibration.” Lower natural frequency indicates better vibration damping, which improves:

- Feel and control in sporting goods like skis and tennis rackets;

- Image quality in camera mounts for drones;

- Accuracy and speed in end-effectors for robots;

- Ride comfort and cabin noise in electric vehicles.

Z-axis carbon fiber ZRT materials used with woven carbon fiber can reduce the natural frequency across all modes of vibration. Photo credit: Boston Materials.

Thermoplastic composites

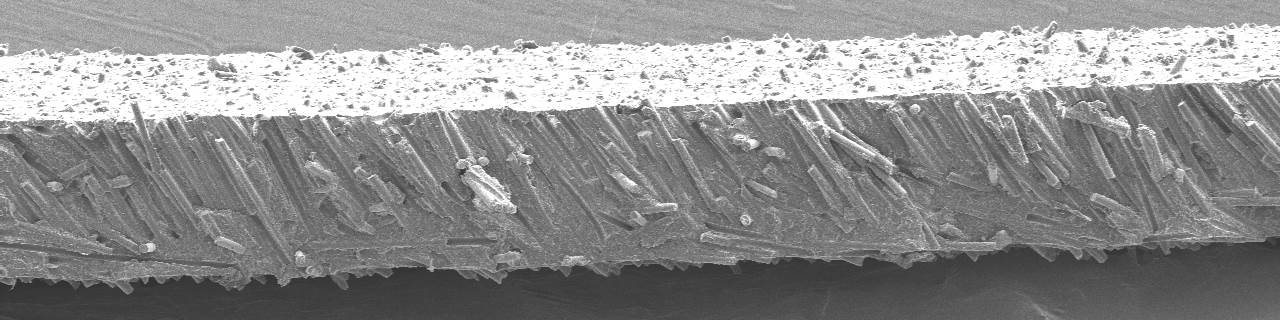

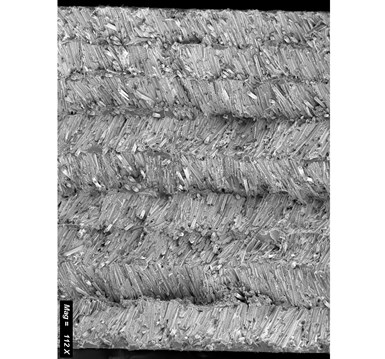

Micrograph of 9-layer ZRT material using polycarbonate matrix. Photo credit: Boston Materials

“We can also add ZRT to thermoplastic films and retain the milled fiberorientation throughout processing,” notes Murthy. This can be seen in the micrograph at left which shows nine plies of ZRT material in a compression molded application. “The polycarbonate matrix used has a much higher viscosity than epoxy resin,” he explains. “This application also used a high compaction pressure of 350 to 400 psi, yet we can retain the z-axis orientation.”

For these thermoplastic composite products, Boston Materials swaps the PET carrier film for a thermoplastic film of the target matrix polymer. Alternatively, it can transfer the ZRT dry film to the target thermoplastic film and melt that into the z-axis carbon fibers in a secondary process. These ZRT thermoplastic products have >50% fiber volume. In addition to polycarbonate, Boston Materials has made ZRT thermoplastic composite films using PPS, PEEK, LMPAEK, PEI, PA-6, PA-12 and bio-PA.

Thermal conductivity for next-gen heat exchangers

Just as ZRT materials enhance electrical conductivity, they also improve thermal conductivity in composites. “Though carbon fiber is thermally conductive along the fiber direction, its conductivity drops by nearly ten-fold perpendicular to the fiber,” explains Gurijala. “Transverse heat transfer is important in applications such as electronic devices, EV battery packs and non-metallic heat exchangers. The ability to tailor the transverse thermal conductivity of polymer composites by placing carbon fiber in the z-axis is a huge benefit for the multifunctional structures being demanded today.”

He notes that PAN-based carbon fiber has an in-fiber thermal conductivity of 15 to 20 watts per meter Kelvin (W/m-K). “This drops by five- to ten-fold at 90 degrees to the fiber,” says Gurijala. “Thus, a composite made with in-plane carbon fiber combined with an insulative polymer matrix at 0.2 W/m-K and having losses at the ply interfaces has an overall transverse thermal conductivity of only 0.7 W/m-K. By adding layers of our PAN-based ZRT materials, we can increase this to around 10 W/m-K.”

However, Boston Materials is also developing ZRT materials using pitch-based carbon fiber which has an in-fiber thermal conductivity of 600 to 900 W/m-K. “Using pitch-based ZRT materials, the theoretical transverse conductivity for a CFRP laminate can reach 250 W/m-K,” says Gurijala, “which then exceeds the thermal conductivity of aluminum.”

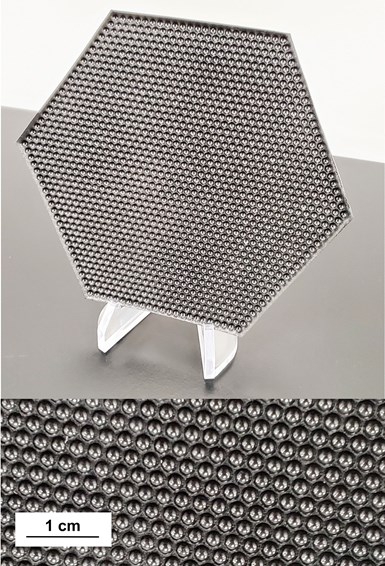

Thermoformed ZRT/PPS film into a complex micro-dimple geometry (minimum feature size of 0.5 millimeters) increases the heat transfer surface area and efficiency for this plate in a non-metallic heat exchanger. Photo credit: Boston Materials

By combining ZRT materials with thermoplastic films, Boston Materials is able to create complex geometries with aluminum-like thermal conductivity. “With our ZRT thermoplastic composite films, low-cost and high-volume thermoforming can be used to produce applications such as non-metallic heat exchanger plates with very small structures to increase surface area,” says Murthy. “This type of part is a real challenge to make with other methods, such as injection molding with conductive molding compounds.” Such plates are used in heat exchangers for residential and commercial heating/ventilation and cooling (HVAC) systems, as well as automotive, aerospace, manufacturing, and industrial process applications. “Metals have long been the material of choice,” he continues, “but they are difficult to process into complex shapes. Heat exchangers now are being asked to provide greater transfer efficiency, environmental stability and lower manufacturing costs. Using thermally conductive composites can meet all of these demands and with lighter weight and corrosion-resistance.”

Boston Materials is also working with a materials supplier to launch a tooling prepreg that heats up more quickly and uniformly for shorter cure cycles and higher dimensional accuracy by reducing mismatches in thermal expansion rates in the x, y, and z directions.

Bimetal and future adoptions

BIMETAL sandwiches a ZRT structural core between two sheet metal skins. Photo credit: Boston Materials

Boston Materials has also developed new materials where its ZRT films act asa structural core, laminated between two layers of sheet metal. “Bimetal is a hybrid material with the same bending properties of sheet metal but with 30-50% lower weight,” says Gurijala. “We developed this for automotive and other industries where there has been interest in CFRP for lightweighting, but low adoption due to carbon fiber’s cost and complexity. Bimetal is like hollow sheet metal, roughly 1-millimeter-thick, with better acoustic and vibration damping properties versus metal.”

What about galvanic corrosion between the metal skins and z-axis milled carbon fibers? “It’s not an issue,” he explains, “because we are using either a resin-rich layer on the metal-mating surfaces of the ZRT films and/or an adhesive or TP film on top. Of course, for titanium, nothing is needed, but we could also use a thin NOMEX aramid fiber or glass fiber veil if the customer felt it was necessary to meet application requirements.” Bimetal blanks are “warm” stamped into components near the melting temperature of the thermoplastic polymer matrix.

Boston Materials is currently working with seven globally recognized manufacturers in consumer electronics, automotive, trucking and aerospace, pursuing product qualifications for local reinforcements, EMI shielding, lightning strike protection, thermal management and vibration damping. Qualifications are expected to be completed by 2022 and the company has plans to announce additional new partnerships, applications, and products.

“We are just at the tip of the iceberg regarding the potential of our z-axis carbon fiber technology,” says Gurijala. “Our goal, ultimately, is to expand the market for composite materials.”

Related Content

McLaren celebrates 10 years of the McLaren P1 hybrid hypercar

Lightweight carbon fiber construction, Formula 1-inspired aerodynamics and high-performance hybrid powertrain technologies hallmark this hybrid vehicle, serve as a springboard for new race cars.

Read MoreAutomotive chassis components lighten up with composites

Composite and hybrid components reduce mass, increase functionality on electric and conventional passenger vehicles.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreRecycling hydrogen tanks to produce automotive structural components

Voith Composites and partners develop recycling solutions for hydrogen storage tanks and manufacturing methods to produce automotive parts from the recycled materials.

Read MoreRead Next

All-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More