CW Blog

CW Trending: democratization of composites

Learn from CW Editors about the trends they are seeing in the democratization of composites.

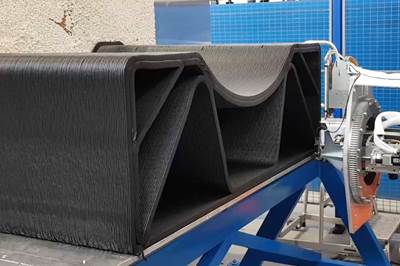

WatchLarge-format, vertical, robotized, fiber-reinforced AM

MTorres joins the large-format AM fray with a system that prints vertically in lengths up to 25 meters.

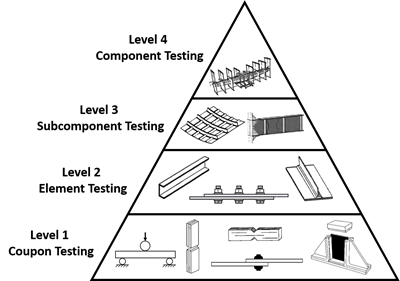

Read MoreComposites testing as part of a building block approach, Part 1: Coupon-level testing

The building block materials testing approach is a step-by-step process that serves as a framework for designing composite structures while also reducing risk and cost.

Read MoreChallenges, opportunities when designing for fiber-reinforced AM

Bridging the gap between as-designed and as-made, and where do you put the fiber?

Read MoreThe evolution of additive composites

Defining additive composites manufacturing and how its merge with conventional processes is providing new solutions and a path forward.

Read MoreSolution-based digital composites fabrication

MIT evolves liquid biomaterials into a new approach for sustainable engineered composite structures.

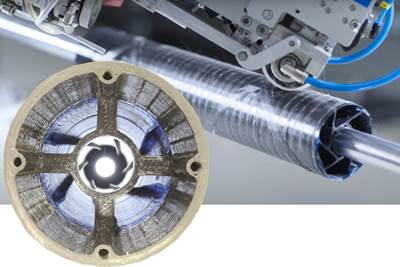

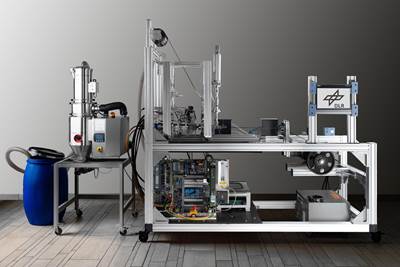

WatchReducing the cost of continuous fiber 3D printing materials

DLR has developed a novel approach to produce thermoplastic impregnated fibers for lower cost versus current slit-tape materials.

Read MoreMultifunctional composite structures across end markets

Innovators find new ways to add functions — from anti-icing to 5G signal transmission to structural batteries and beyond — into structural composites.

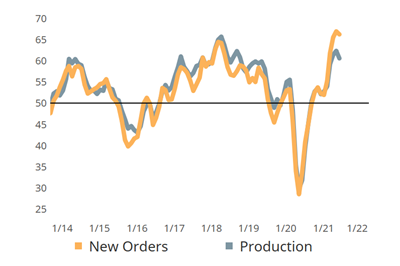

Read MoreComposites Index sets two all-time highs in three months

Supported by strong business conditions and struggling supply chains, the June Composites Index set a new high reading.

Read MoreAdditive manufacturing adds versatility to large marine structures

Dive Technologies and Moi Composites are among those extending composite 3D printing’s design flexibility past prototyping and into customizable end-use parts.

Read MoreCW Trending: A New Video Series From CompositesWorld

CW Trending features subject-matter experts, material suppliers, technology mavens and CW’s own editors to explore the ideas, technologies, trends and innovations in development or already in the marketplace.

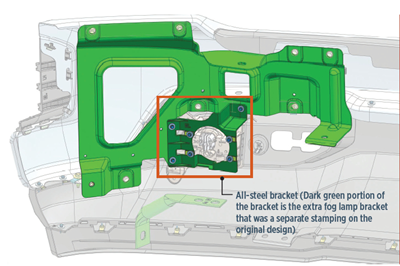

WatchThermoplastic composites: Structural bumper bracket

Hybrid bracket reduces mass, increases design flexibility, package space in pickup front bumper.

Read More