CW Blog

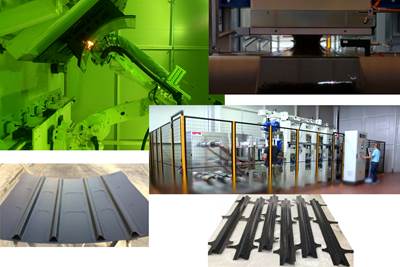

Bespoke process produces composite brake pedal every minute

Three composite materials are used to create structural composite member that meets demanding mechanical requirements.

Read MoreThermoplastic composite structure replaces metals on safety-critical brake pedals

First all-composite brake pedals developed by Boge Rubber & Plastics Group are lighter, stiffer, stronger and offer improved driving haptics.

Read MoreMultilayer thermoplastic tapes, AFP and resin infusion for more democratic composites

Novotech advances new materials and more affordable automated processes for small aircraft and beyond

WatchPratt & Whitney to produce advanced metal and CMC turbine airfoils in North Carolina

New 1 million-square-foot production facility follows CMC R&D center and publicized strategy for next-gen engines.

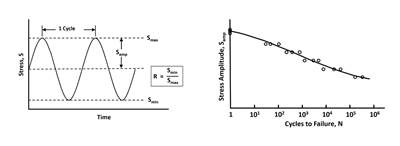

Read MoreFatigue testing of composites

Fatigue testing may be performed at multiple points during the design of a composite structure. A focus on small-specimen level fatigue test methods, however, suggests a need for more testing method standardization.

Read More3D-printed prefab homes aim to disrupt construction market

California startup Mighty Buildings’ award-winning prefabricated building production process relies on large-format 3D printing, UV-curable resins, digital design and automation.

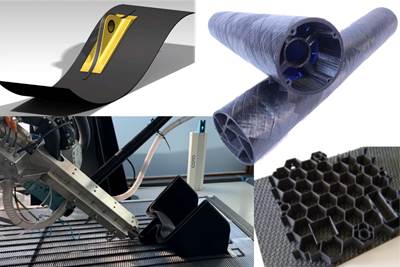

WatchORNL develops 3D-printed composite machine base

In a recently reported project from Oak Ridge National Laboratory, carbon fiber and large-format 3D printing were used to help create a solution for machine tool outsourcing.

Read MoreThe Gardner Editors' Great Big 2020 Holiday Gift Guide

Our hand-picked holiday gift guide for the composite lovers, Metalworkers, Machinists, Mold Makers, Processors, Welders, Finishers, Engineers and Makers in your life.

Read MoreMultifunctional epoxy formulations show potential for future composite manufacturing

Study results from Swinburne University show highly increased cure time as well as reduced cure temperatures. Further research hopes to enable faster, higher-volume composites 3D printing and other processes.

Read MoreEpisode 35: Lisa Ketelsen, Covestro

CW Talks visits with Lisa Ketelsen, head of thermoplastic composites and CEO of Maezio at Covestro. Ketelsen talks about her path to Covestro and the Maezio product line, Maezio’s attributes and applications, and how she sees thermoplastic composites evolving in the marketplace.

ListenFuture composite manufacturing - AFP and Additive Manufacturing

TU Munich symposium explores how these technologies are merging and reviews R&D that is creating a path forward.

Read More2020 CW Top Shops recognizes top-performing facilities

CW's second annual Top Shops benchmarking survey helps composites fabricators put their operations into perspective and illuminates top-ranking facilities.

Read More