CW Blog

And the winners are...

As 2020 comes to an end, CW Editor-in-Chief Jeff Sloan takes a look at the stories over the last 12 months that garnered the most attention on the CW website.

Read MoreTech Table: Compression molding machines

CW’s third Tech Table represents compression molding machine data collected from information provided by suppliers.

Read MoreSouth Korean carbon fiber recycling start-up scales up

With plans for growth, CATACK-H claims its solvolysis-based recycling process can reclaim high-quality fibers and resins from materials and finished parts.

Read MorePart 2: Applying CT scan data analysis and visualization to composites

Advanced CT-scan analyses can offer deep insight into challenges faced when examining novel composites and hybrid material behavior or performing quality and certification testing. Part two of a two-part series.

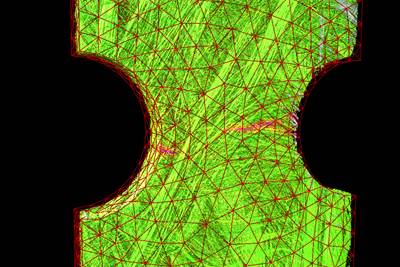

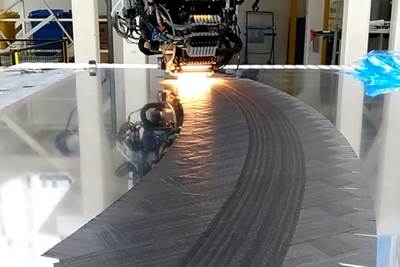

Read MoreAFP tow steering comes of age, Part 1: Current state

It used to be enough that AFP systems could precisely and quickly place and cut multiple tows to build complex aerostructures. Now, fabricators need those tows steered, and the tighter the radius, the better.

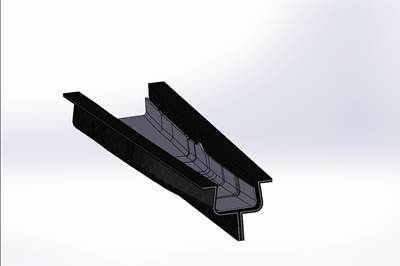

WatchHybrid, large-format additive tooling: Lighter, faster, less costly molds for big parts

Additively manufactured cores, CFRP face skins produce large tools for prototype, low-volume aerostructure parts.

Read MoreAutomated Composites Knowledge Center

Here, in the Automated Composites Knowledge Center, CGTech brings you vital information about all things automated composites.

Read MoreCloudy skies ahead for composites

In light of the uncertainty the composites industry faces, business travel, the supply chain and the inability to develop next-generation leaders are concerns to watch for leading into 2021.

Read MoreComposites activity expansion quickens in October

Seasonal shipping rush sends supplier delivery reading higher, marking the first time since mid-2019 that the Index reported two consecutive months of expanding business activity.

Read MoreComposites meet precision, weight goals for complex facade design

Brazilian fabricator Gatron manufactured 3,000 square meters of curved composite frames to support a 33-floor residential building.

Read MoreNext-generation aerospace mold release application

Chem-Trend reviews three application techniques and strategies for its Zyvax® 1070W aerospace mold release system.

WatchItalian student design team uses composites to improve automotive performance

Politecnico di Milano’s Formula SAE team worked with Exel Composites to transition to lighter, better-performing composite vehicle components.

Read More