CW Blog

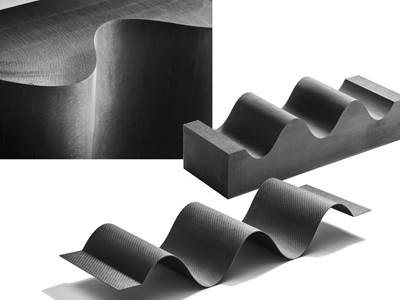

Mechanical testing of textile composites

Standardized mechanical testing methods abound, but they often focus on composites with unidirectional layers. Here are some modifications to common test methods for testing textile composites.

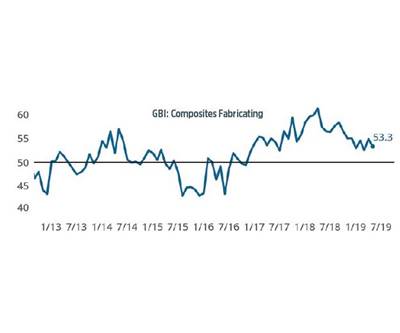

Read MoreIndex activity expands, led by production

The Composites Fabricating Index for May 2019 came in at 53.3, led higher by production activity.

Read MoreAcrylonitrile from biomass scales up

Affordable, sustainable, efficient manufacture of biomass-based acrylonitrile — the primary feedstock of carbon fiber production — is leaving the lab and entering the real world.

Read MoreCutting the cost and time of tooling for composites

New 360 material achieves CFRP/Invar tool performance with less investment.

Read MoreThe future of composites: The next generation

Columnist Dale Brosius reflects on what professional societies like SPE and SAMPE are doing to engage the next generation of composites leaders.

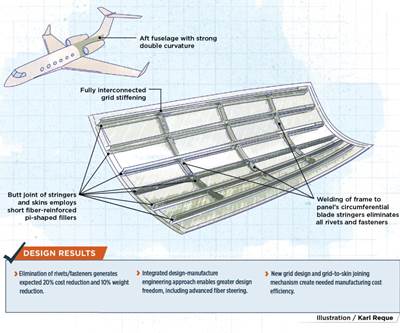

Read MoreThermoplastic primary aerostructures take another step forward

Employing new manufacturing techniques and the design freedom they create, GKN Fokker has joined forces with Gulfstream to assess thermoplastic composites for primary aircraft structures.

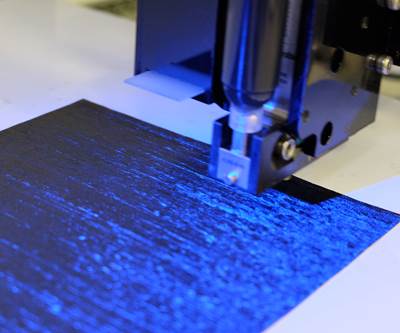

Read MoreEvolving AFP for the next generation

‘Aerospace quality at automotive pace’ is the mantra of the supply chain being developed for next-generation commercial aircraft. Automation is evolving to meet the challenge.

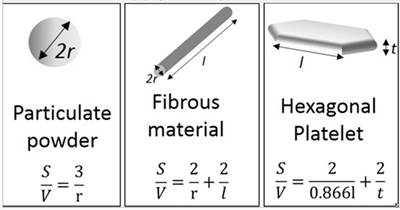

Read MoreNanomaterial types and definitions

Nanomaterials range in size, material, characteristics and usage in composites manufacturing. Provided here are types and definitions of those currently available.

Read MoreNanomaterials: Products, supply chain mature for next-gen composites

Development spans 3D and thermoplastic nanocomposites, nano-CMCs for hypersonics and nanomaterials safety and toxicity.

Read More2019 Paris Air Show: Highlights

The 2019 Paris Air Show may have lacked the glamour of a new aircraft program announcement, but the composites industry represented is clearly gearing up for next-generation aerospace manufacturing.

WatchNatural fiber composites: What’s holding them back?

Natural fiber reinforcements have been available for some time, but factors such as compatibility with current processes and geographic availability continue to limit widespread use.

Read MoreFRP pultrusions replace wood for structural applications

Unlike wood, fiber-reinforced polymer (FRP) is unaffected by salt spray, moisture or prolonged immersion in water, making it a good material choice for structural applications in harsh environments.

Read More

.jpg;maxWidth=400;quality=70)