Nanomaterial types and definitions

Nanomaterials range in size, material, characteristics and usage in composites manufacturing. Provided here are types and definitions of those currently available.

Nanomaterials range in size, material, characteristics and usage in composites manufacturing. Below are types and definitions of those currently available.

See “Nanomaterials: Products, supply chain mature for next-gen composites" from CW’s June 2019 issue for more on the current landscape for nanomaterials and nanocomposites.

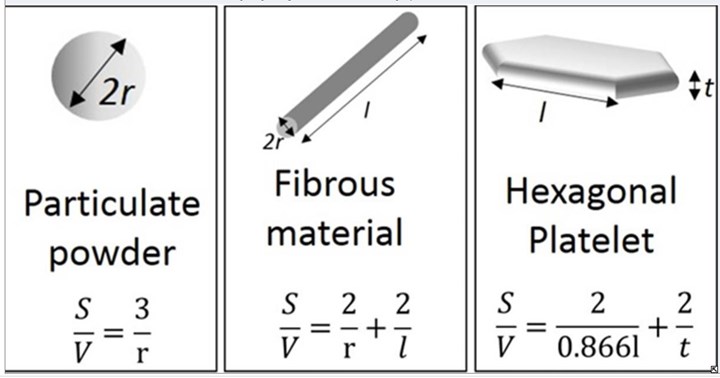

Nanoparticles (nanopowder, nanoclusters, nanocrystals) are sized less than 100 nanometers in diameter and are commonly produced by reducing ceramic or metal powder via ball milling, where media in a rotating chamber are ground finer in size. An example is nanosilica particles used in epoxy resin for 3M Fortified Tooling Prepreg that achieves multiple improvements versus epoxy without nanosilica including: 55% higher resin fracture toughness (KIC), 17% higher laminate shear strength and 59% higher composite hardness while reducing springback by 47%, exotherm by 61% and shrinkage by 33%.

Source | “Structural Ceramic Nanocompo-sites: A Review of Properties and Powders’ Synthesis Methods” by Paola Palmero, Nanomaterials (Basel). June 2015

Nanofibers have diameters less than 100 nanometers and a high aspect ratio. One example is carbon nanofibers (CNFs), which can measure up to 300 micrometers long. Nanofibers are produced from a variety of metals, ceramics, polymers and natural materials such as cellulose and chitin (the protein that makes up crustacean shells). Electrospinning is a common manufacturing technique. An example is cellulose nanofibers, which are being evaluated for low-cost, lightweight composites in ballistic armor, spacecraft, automotive body and interiors and aircraft interiors.

Nanoplatelets are 2D stacks of nanomaterials that may be made from metals, ceramics or graphene. Graphene is most commonly used in composites manufacturing and is comprised of a single-atom-thick layer of carbon. Graphene nanoplatelets made by Applied Graphene Materials (Redcar, U.K.) are described as 1-10 nanometers thick and 1-15 micrometers in diameter, resulting in aspect ratios up to 1:1000 and surface areas up to 700 m2/g. The platelet shape provides edges that are more readily functionalized for improved dispersion in polymers.

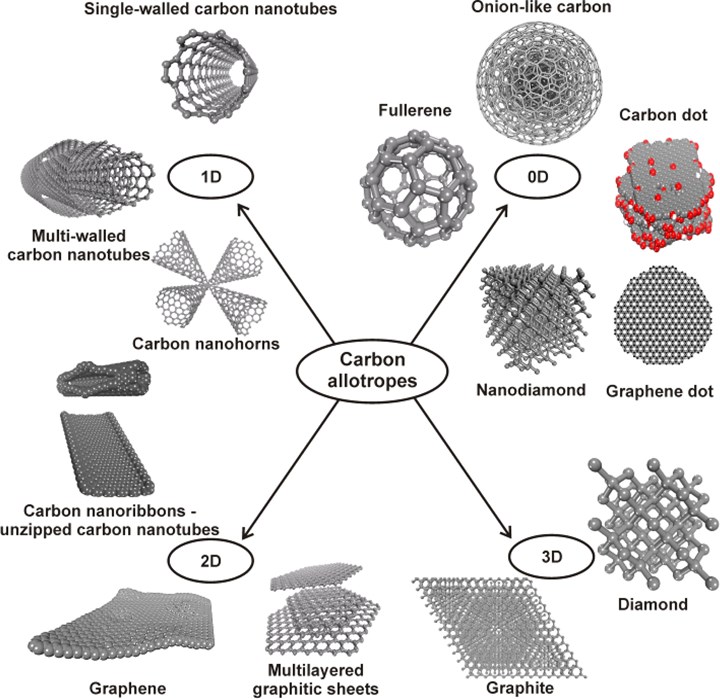

Nanocarbon comprises many allotropes. These are the same element — carbon (C) — but with different arrangements of atoms (see image below), and include carbon and graphene dots, graphene sheets and platelets, and graphene rolled into high-aspect-ratio carbon nanotubes (CNTs) — sphere-like buckyballs/fullerenes and multilayered nano-onions. CNTs may be slit open to produce nanoribbons. CNTs may also be spun into macroscale fibers for use in composite laminates.

Source | “Broad Family of Carbon Nanoallotropes: Classification, Chemistry, and Applications of Fullerenes, Carbon Dots, Nanotubes, Graphene, ... ” by Zboril, Radek, et. al., Chemical Reviews, May 2015. American Chemical Society.

Related Content

-

The next evolution in AFP

Automated fiber placement develops into more compact, flexible, modular and digitized systems with multi-material and process capabilities.

-

The future of quartz and oxide fibers at Saint-Gobain Advanced Ceramic Composites

New business builds on 100-year legacy in quartz, prepares for growth, while starting production of oxide fibers to meet increased demand for CMC by aerospace and industrial sectors.

-

Composites end markets: Electronics (2024)

Increasingly, prototype and production-ready smart devices featuring thermoplastic composite cases and other components provide lightweight, optimized sustainable alternatives to metal.