CW Blog

Subscribe to CompositesWorld Magazine

CompositesWorld Magazine is a monthly print publication free to qualified individuals.

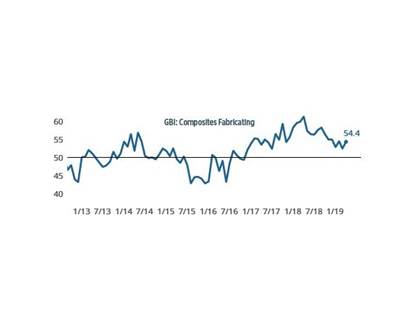

Read MoreIndex rises on surging new orders activity

The Composites Business Index moved higher in April 2019 due to strong acceleration in new orders activity.

Read MoreNext-Gen Aerospace Special Edition

Read the Next-Generation Aerospace Special Edition, produced in partnership with CompositesWorld, Modern Machine Shop and Additive Manufacturing.

Read MoreNext-generation aerospace: shaping the supply chain landscape

The global commercial aerospace industry is at a unique time.

Read MoreCarbon fiber-reinforced parts 3D-printed for catamaran

A Swiss engineering company combined 3D printing, bonding technology and carbon fiber composites to develop lighter, more efficient marine bearing cages.

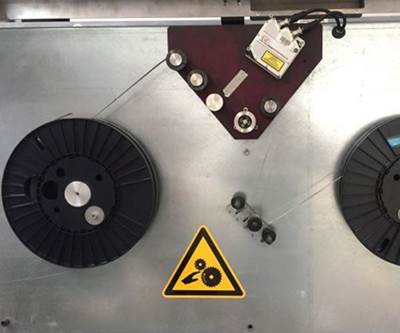

Read MoreMeasuring thermoplastic prepreg tape quality for part process control

Low-cost tests measuring dimensions, thermal behavior and consolidation predict CFRTP part quality.

Read MoreIndustrialized continuous fiber composite printing in Delft

CEAD offers large builds with speed, precision, low-cost extrusion and continuous fiber.

WatchWhat does the future hold for Bombardier Belfast?

Bombardier Belfast, fabricator of the infused composite wings for the Airbus A220 single-aisle aircraft, is for sale. The ownership under which this facility lands may say a lot about the future of infusion in large aerostructures.

Read MoreSpace: The next frontier and battleground

CW Editor-in-Chief Jeff Sloan reflects on the goals outlined leaders for space travel at the 35th Space Symposium – exploration, commercial travel and military defense among them – and the role of composites in the vehicles under development to reach them.

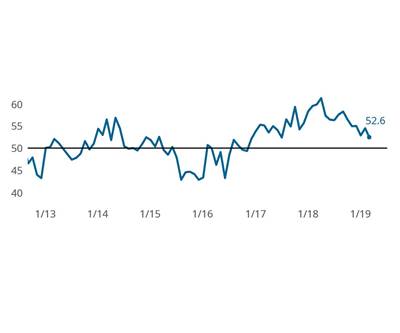

Read MoreIndex shows modest expansion on production and supplier delivery activity

The Composites Business Index moved lower in March as backlogs contracted, resulting from slowing of the previous month’s new orders growth and increased production activity.

Read MoreHybrid resin system: Epoxy benefits, without the epoxy

Rapid cure, zero tack material ideal for automated, higher-volume production.

Read MoreFusing waterjet, laser for efficiency in CFRP/CMC machining

Laser MicroJet technology offers high accuracy and speed without heat issues, burring or replacement of cutting tools.

Read More