Mechanical testing of textile composites

Standardized mechanical testing methods abound, but they often focus on composites with unidirectional layers. Here are some modifications to common test methods for testing textile composites.

Although standardized test methods for fiber-reinforced composites are used for a wide variety of fiber forms, most of these test methods were developed with a focus on composites with continuous fibers aligned in unidirectional layers. Typically available as prepreg tape, these unidirectional material forms are commonly used in aerospace and other industries because they provide the highest stiffness and strength. However, many other continuous fiber forms are commonly used, including woven and braided fabric layers. For these textile composites, it’s often necessary to modify the standardized test methods and consider other specialized methods as well. In this column, we consider the aspects of textile composites that require special test considerations as well as the most common modifications made to test methods to accommodate them.

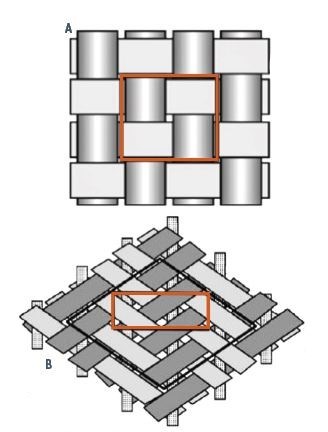

Fig. 1 Example unit cells for textile composites. Shown are a two-dimensional weave (A) and a triaxial braid (B) Source | ASTM D6856

Perhaps the most significant test method modifications for textile composites result from textile composites’ periodic geometry, which is produced by their undulating fiber tows. This repeating pattern of the textile architecture allows for a unit cell to be identified, defined as the smallest geometric element of the textile architecture that represents the periodic textile pattern. Examples of a unit cell for a two-dimensional weave and a triaxial braid are shown in Fig. 1. Under uniform loading, these textile architectures produce strains that can vary in magnitude by a factor of three within a unit cell1. Since these mechanical tests are intended to obtain average or bulk properties of the textile composite, the test section of the specimen must be sized appropriately. As a result, the identification of the material’s unit cell size is an important step in establishing the required dimensions of the test specimen.

Having identified the unit cell for a textile composite, the next step in sizing the test specimen is to consult the standardized test method of interest for guidance. The most commonly used ASTM test methods for tension testing (ASTM D30392) and compression testing (ASTM D34103 and ASTM D66414) specify specimen widths for different fiber orientations, including 0-degree unidirectional (10-15-millimeter), 90-degree unidirectional (25-millimeter) and specially orthotropic (balanced and symmetric, 25-millimeter) laminates. Having two or more fiber orientations, textile composites fit best into the specially orthotropic category, and therefore a specimen width of 25 millimeters is commonly used for tension and compression testing. However, additional guidance is provided in ASTM D68565, a standard guide for testing fabric-reinforced “textile” composites. An additional recommendation provided in ASTM D6856 is that the specimen width be at least twice the unit cell width for textile composites.

For stiffness measurements of textile composites, the measured strains should correspond to the bulk material response, and therefore need to be measured over a sufficiently large area to produce the average strain. Comprehensive studies performed as part of the NASA Mechanics of Textile Composites Program in the early 1990s resulted in guidelines for both strain gage size and extensometer gage length for textile composites1,6, which were later incorporated into the ASTM D6856 standard guide. Research results showed that strain gages should be at least one unit cell in length, and have a width that is at least half the unit cell length. Similarly, a minimum extensometer gage length of one unit cell length is recommended. For relatively coarse textile composites with larger unit cell sizes, the use of extensometers becomes increasingly attractive due to the significant increase in strain gage cost associated with increased size.

Although the periodic geometry of textile composites places additional requirements on specimen sizing and strain measurements, the reduced strength of textile composites in comparison to unidirectional composite laminates generally simplifies mechanical testing. These strength reductions result from the smaller percentage of fibers oriented in the loading direction as well as fiber tow undulations in the textile architecture. Whereas 0-degree unidirectional laminates typically require the use of tabbed tension specimens to produce a built-up specimen thickness in the gripping regions, many textile composites may be successfully tension tested using width-tapered “dog bone” shaped specimens, similar to those used for unreinforced plastics7. Although the use of dog bone-shaped textile composite specimens eliminates the need for bonded end tabs, they have not gained widespread acceptance in the advanced composites industry and have not been standardized by ASTM.

For compression testing, an added complication is the requirement of a relatively short unsupported test section to prevent specimen buckling prior to compression failure. The need for at least one complete unit cell length for strain measurement and the desire for multiple unit cell lengths in the test section makes specimen design challenging. However, a longer unsupported test section is possible when the specimen thickness is increased, and guidance on suitable specimen thicknesses is available in the two ASTM compression test methods mentioned previously. Note that for textile composites with reduced compression strengths relative to 0-degree unidirectional laminates, the use of untabbed specimens makes the Combined Loading Compression (CLC) test method, ASTM D6641, an attractive candidate. An additional option of pure end-loaded compression testing is possible for many textile composites as well.

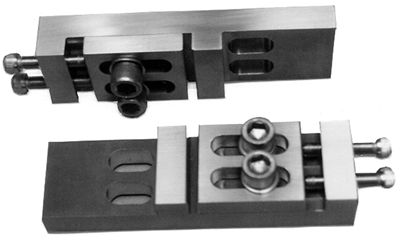

Fig. 2 NASA short block compression test fixtures. Photo | Dan Adams

As an example, the NASA short block compression test8 has been used successfully for compression testing woven and braided textile composites. The test fixture (Fig. 2) applies a small clamping force at the specimen ends to prevent brooming prior to compression failure. A 38-millimeter wide specimen is used, and end clamping takes place over 6-millimeter lengths at the specimen’s ends. The length of the unsupported test section is established based on the specimen thickness and buckling considerations. Typical specimen thicknesses are in the range of 5-7 millimeters and overall specimen lengths range from 40 to 55 millimeters. Although this test is simple to perform and uses relatively small, untabbed specimens, it has not received considerable attention and has not been standardized to date.

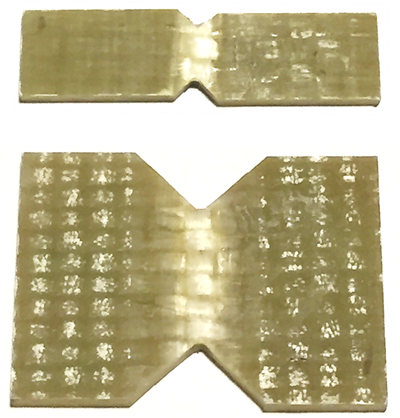

Fig. 3 V-notched shear test specimens; ASTM D5379 specimen (top) and ASTM D7078 specimen (bottom). Source | Wyoming Test Fixtures Inc.

In-plane shear testing of woven textile composites can be performed with the commonly used ±45 tensile shear test, ASTM D35189, but only for woven fabrics or biaxial braids in which identical fiber tows are placed in the +45-degree and -45-degree orientations, producing the required ±45-degree balanced laminate. For unbalanced weaves and other textile architectures, V-notched shear test methods are typically used. The V-notched beam (Iosipescu) shear test, ASTM D537910, is an attractive candidate for textile composites with relatively small unit cell sizes less than 4 millimeters. For larger unit cell sizes, the V-notched rail shear test method, ASTM D707811, is preferred because the test section between the V notches is scaled up by a factor of three relative to the Iosipescu specimen (Fig. 3).

In general, structural test methods using large specimen sizes may be used for textile composites without modification of the specimen size or loading method. This includes open-hole tension and compression testing for notch sensitivity and compression-after-impact testing for damage tolerance. However, the selection of strain gages and extensometers should follow the sizing guidelines provided in the ASTM D6856 standard guide and other relevant ASTM guidelines.

References

1J. E. Masters, “Strain Gage Selection Criteria for Textile Composite Materials,” NASA Contractors Report 198286, Feb. 1996.

2ASTM D3039/D3039M-17, “Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials,” ASTM International (W. Conshohocken, PA, US), 2017 (first issued in 1971).

3ASTM D3410/D3410M-16, “Standard Test Method for Compressive Properties of Polymer Matrix Composite Materials with Unsupported Gage Section by Shear Loading,” ASTM International (W. Conshohocken, PA, US), 2016 (first issued in 1975).

4ASTM D6641/D6641M-16, “Standard Test Method for Compressive Properties of Polymer Matrix Composite Materials Using a Combined Loading Compression (CLC) Test Fixture,” ASTM International (W. Conshohocken, PA, US), 2016 (first issued in 2001).

5ASTM D6856/D6856M-03 (2016), “Standard Guide for Testing Fabric-Reinforced “Textile” Composite Materials,” ASTM International (W. Conshohocken, PA, US), 2016 (first issued in 2003).

6J. E. Masters and M. A. Portanova, “Standard Test Methods for Textile Composites,” NASA Contractors Report 4751, Sept. 1996.

7M. A. Portanova, “Standard Methods for Unnotched Tension Testing of Textile Composites,” NASA Contractors Report 198264, Dec. 1995.

8J. E. Masters, “Compression Testing of Textile Composites,” NASA Contractors Report 198285, Feb. 1996.

9ASTM D3518/D3518M-18 (2018), “Standard Test Method for In-Plane Shear Response of Polymer Matrix Composite Materials by Tensile Test of a ±45° Laminate," ASTM International (W. Conshohocken, PA, US), 2018.

10ASTM D5379/D5379M-12, “Standard Test Method for Shear Properties of Composite Materials by the V-Notched Beam Method,” ASTM International (W. Conshohocken, PA, US), 2012 (first issued in 1993).

11ASTM D7078/D7078M-12, “Standard Test Method for Shear Properties of Composite Materials by the V-Notched Rail Shear Method,” ASTM International (W. Conshohocken, PA, US), 2012 (first issued in 2005).

Related Content

Active core molding: A new way to make composite parts

Koridion expandable material is combined with induction-heated molds to make high-quality, complex-shaped parts in minutes with 40% less material and 90% less energy, unlocking new possibilities in design and production.

Read More3D-printed CFRP tools for serial production of composite landing flaps

GKN Aerospace Munich and CEAD develop printed tooling with short and continuous fiber that reduces cost and increases sustainability for composites production.

Read MoreJeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

Read MoreImproving carbon fiber SMC simulation for aerospace parts

Simutence and Engenuity demonstrate a virtual process chain enabling evaluation of process-induced fiber orientations for improved structural simulation and failure load prediction of a composite wing rib.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More