The evolution of infusion

As resin infusion continues to infiltrate composites, fabricators across the market spectrum drive materials and process developments in pursuit of process control.

Read MoreTemperature control heats up

Faster infusion is one way to reduce cycle time, but another is faster cure, which typically requires an elevated temperature.

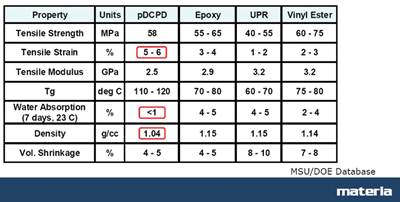

Read MoreBackgrounder: Proxima pDCPD

Materia Inc.'s (Pasadena, Calif.) Proxima, a completely new type of polydicyclopentadiene (pDCPD) thermoset resin, is said to offer the same mechanical properties as, and better long-term durability than, epoxy

Read MoreInfused CFRP: New One-Design paradigm

The Farr 400 opens a new frontier in Grand Prix sail racing, with greater precision at lower cost.

Read MoreSailboat building in the blood

Founded by Hannes Waimer, Premier Composite Technologies (PCT, Dubai, United Arab Emirates) is the latest incarnation of a family enterprise that has built Farr One-Design boats for more than 20 years.

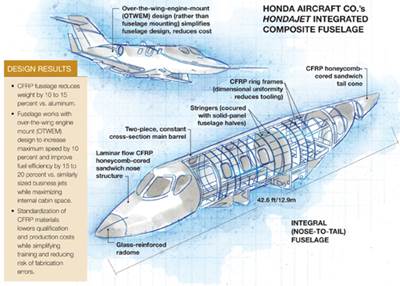

Read MoreComposite fuselage helps HondaJet upend biz-jet market

CFRP composites enable unitized structure with low-drag aerodynamics that transform aircraft performance and reduce cost.

Read MoreThermoplastic Wind Blades: To be or not?

Will future wind blades incorporate thermoplastic composites? It depends on whom you ask.

Read MoreBig parts? Big tooling breakthrough

Electrically heated carbon fiber/PEEK/ceramic tooling and powdered epoxy resin system could revolutionize production of large composite aerospace structures.

Read MorePatented MECHTool system

Galway, Ireland-based ÉireComposites’ patented MECHTool (Mold Efficient Cooling and Heating) system was developed to replace traditional ovens in a number of thermoplastic molding processes.

Read MoreForging variations

Developed in parallel to the Duqueine Group’s (Massieux, France) MFP process, the high-pressure molding process used by Lentilly, France-based Carbone Forgé is described by Vincent Duqueine as “enabling forging of composites, similar to that done with metals.”

Read MoreForged composites replace complex metal parts

Powerhouse manufacturer’s high-pressure compression molding process forms prepregged CFRP components with forged-metal properties.

Read MoreBlade cycle time: 37 percent faster

Ongoing private/public effort to optimize blade manufacturing targets current production and anticipates “next-generation” offshore applications.

Read More