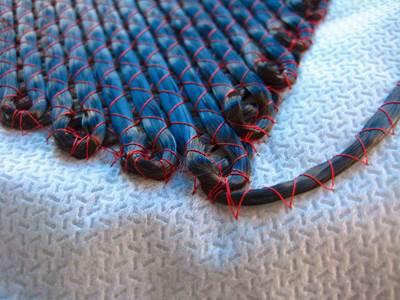

Tailored Fiber Placement: Besting metal in volume production

Affordable automated production of highly optimized preforms and parts.

Read MoreTooling up for larger launch vehicles

NASA and Janicki Industries demonstrate composites’ cost advantage in tooling for fabrication of 10m/33 ft diameter payload fairing for next-generation launch vehicle.

Read MoreModular design eases big wind blade build

First segmented composite blade increases power generation, eases installation and keeps weight and costs in check.

Read MoreBig blades, big innovations

In the process of designing its G128 wind turbine blade and the INNOBLADE segmented blade technology that simplifies its transport (see “Modular design eases big wind blade build,” under “Editor’s Picks,” at top right), Gamesa (Vizcaya, Spain) has introduced several innovative auxiliary technologies that reduce cost and simplify processing, particularly in the context of blade delivery and installation.

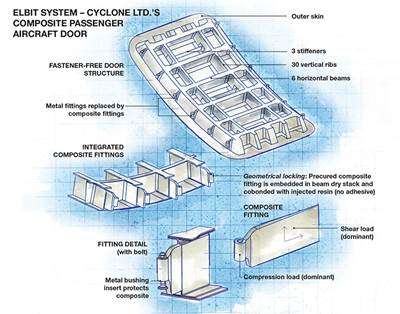

Read MoreCutting the cost of integrated composite aerostructures

A unitized all-composite aircraft door concept is realized in one shot with no fasteners.

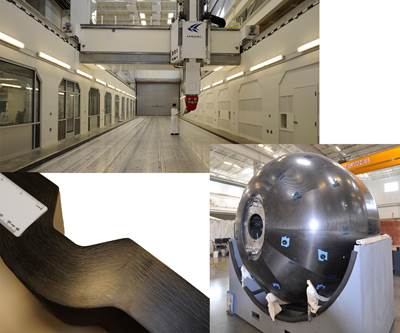

Read MoreBig machines, small tolerances

An examination of the lengths Janicki Industries (Sedro-Woolley, Wash.) goes to ensure dimensional precision in its massive CNC-machining operations.

Read MoreJanicki Industries: Breaking the mold

Once known only as a toolmaker, Janicki offers unique precision, production capability and problem solving as it pioneers leading-edge composites technology.

Read MoreComposites aid connectivity on commercial aircraft

General Dynamics’ triband radome helps LiveTV team overcome transmissivity challenges during development of in-flight broadband services.

Read MoreFlow-front dynamics: Heat and vacuum hold

Three infusion experts talk about ways and means to avoid erratic flow fronts during resin infusion processes.

Read MoreAiming infusion at the application

With so many process variables to play with, how do you know which new solutions that promise better, faster infusion are right for your application?

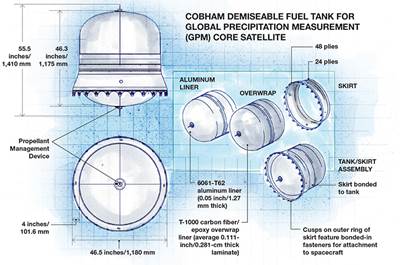

Read MoreGPM mission: Better climate data

Global Precipitation Measurement (GPM) is an international satellite mission designed to provide next-generation observations of rain and snow worldwide every three hours.

Read MoreSpace mission maximized via minimized survivability

CFRP design and manufacturing flexibility prove key in first spacecraft fuel tank designed to disintegrate upon reentry for improved mission efficiency and debris mitigation.

Read More