Composite Recycling Technology Center launches recycled carbon fiber sports bench

The bench, launched with the remodel of a Washington-based aquatic center, is said to be durable and easy to clean for sports and aquatic facilities.

Read MoreSouth Korean carbon fiber recycling start-up scales up

With plans for growth, CATACK-H claims its solvolysis-based recycling process can reclaim high-quality fibers and resins from materials and finished parts.

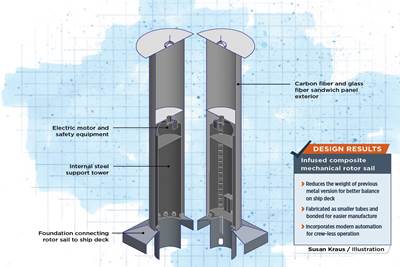

Read MoreModernizing the mechanical rotor sail

Composites are key for Norsepower’s award-winning redesign of a century-old rotor sail for reducing carbon emissions on passenger and cargo ships.

Read MoreComposites meet precision, weight goals for complex facade design

Brazilian fabricator Gatron manufactured 3,000 square meters of curved composite frames to support a 33-floor residential building.

Read MoreStrength of composite whale tail sculpture saves runaway train car

A 19-year-old, glass fiber-reinforced composite urban sculpture designed by Dutch engineering firm Solico was able to safely bear the weight of an off-track rail vehicle.

Read MoreItalian student design team uses composites to improve automotive performance

Politecnico di Milano’s Formula SAE team worked with Exel Composites to transition to lighter, better-performing composite vehicle components.

Read MoreDassault Systèmes, Purdue establish center of excellence

The 3DEXPERIENCE Education Center of Excellence in Advanced Composites at Purdue University aims to educate the next-generation workforce and accelerate Industry 4.0.

Read MorePolestar announces production plans for natural composites-intensive BEV

The Precept battery electric vehicle, developed by Volvo’s Polestar brand, is said to feature Bcomp interior and exterior flax fiber composite panels.

WatchFirefly Aerospace to automate composite rocket production with Ingersoll AFP machine

The company plans to transition manufacture of its Alpha and Beta all-composite launch vehicles to automated fiber placement starting in 2021.

Read MoreBraided preforms meet phase-change tooling

A program from the U.S. Air Force Research Laboratory adopts automated braiding and phase-change tooling for a complex geometry unmanned aircraft part.

WatchMoving forward on the Multifunctional Fuselage Demonstrator (MFFD)

Clean Sky 2’s MFFD program continues to move toward its goal of delivering a welded, thermoplastic composite fuselage demonstrator using next-generation manufacturing processes.

Read MoreReprocessable thermosets and thermoplastic epoxies: An expanding landscape

New chemistries give thermosets new thermoplastic-like versatility.

Read More.jpg;maxWidth=250;quality=70)