AIMS Metrology introduces coordinate measurement machine for large parts inspection

Suited for composites applications in a range of industries, the Summit is engineered with a 5-axis scanning probe, REVO-2 sensors and options for automation.

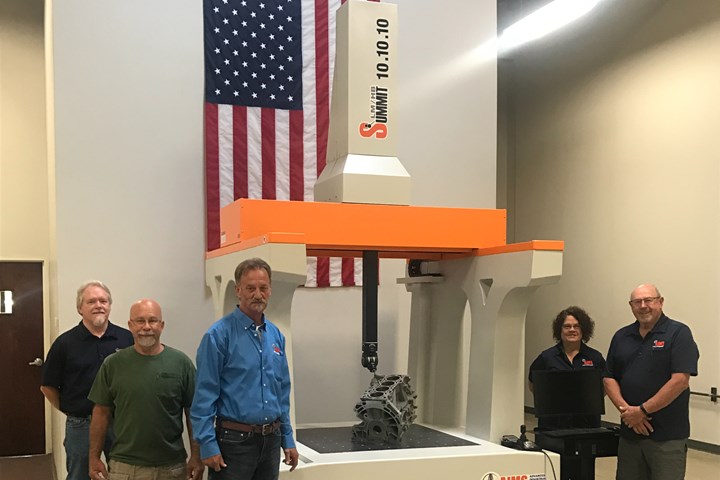

Coordinate measuring machines (CMM) company AIMS Metrology (Dayton, Ohio, U.S.) recently introduced its Summit 10.10.10 CMM. Engineered with a 5-axis REVO-2 dynamic scanning probe and 1 meter cubed capacity, the Summit is said enable high volume and large parts inspection. Suitable for a range of industries such as automotive, aerospace and medical companies, the CMM can be automated with a robot load/unload system or a conveyor. According to the company, the Summit is suited for applications with composite materials, as well as metal and others.

In 2015, AIMS Metrology released its first job shop CMM, the Revolution Series HB, which is a 5-axis mobile CMM with a PH20 touch trigger indexing head. Released in July 2020, the Summit is a stationary model with a workpiece weight of 2,200 kg while preserving facility floor space, the company says. According to Mark Gearding, VP of AIMS, the Summit was developed for customers needing large inspection capacity enhanced with REVO-2 sensors such as RVP vision and SFP2 surface measurement.

The REVO-2 is said to provide measuring speeds up to 500 mm/second and data collection rates of up to 4,000 points per second for increased part throughput. Rapid calibration for all positions expands uptime. Infinite positioning and 5-axis motion are said to offer easy access to difficult features, and flexible tip sensing aids accuracy and flexibility.

Dual linear motors work off durable, permanent magnets. AIMS says its design minimizes wear and tear for zero maintenance and enhanced uptime. The Summit’s polymer-cast base has built-in vibration resistance and thermal stability for longer life and greater accuracy, the company says, and uses 110/220 volt outlets to eliminate the need for shop air. In addition to robotic or pass through conveyor automation, the Summit can also be equipped with automatic tool adjustment for tool wear.

According to AIMS Metrology, Honda Transmission Manufacturing of America Inc. is an early adopter of the Summit system.

Related Content

-

3D-printed CFRP tools for serial production of composite landing flaps

GKN Aerospace Munich and CEAD develop printed tooling with short and continuous fiber that reduces cost and increases sustainability for composites production.

-

Optimizing a thermoplastic composite helicopter door hinge

9T Labs used Additive Fusion Technology to iterate CFRTP designs, fully exploit continuous fiber printing and outperform stainless steel and black metal designs in failure load and weight.

-

Composite sidewall cover expands options for fire-safe rail components

R&D project by CG Rail explores use of carbon fiber-reinforced thermoplastics and recycled manufacturing scrap to meet fire safety, weight and volume targets.

.jpg;width=70;height=70;mode=crop)