Bigger, better, faster, more

Editor-in-chief Jeff Sloan considers the implications of propitious aircraft OEM announcements for the aerocomposites supply chain.

Read MoreAcrylonitrile from biomass scales up

Affordable, sustainable, efficient manufacture of biomass-based acrylonitrile — the primary feedstock of carbon fiber production — is leaving the lab and entering the real world.

Read MoreGrid/skin structures explained

Composites expert and veteran Stephen Tsai and automated tape and fiber placement specialist MTorres have published “Composite Double-Double and Grid/Skin Structures: Low Weight/Low Cost Design and Manufacturing,” a design and manufacturing guide for the fabrication of grid-stiffened composite structures.

Read MoreEvolving AFP for the next generation

‘Aerospace quality at automotive pace’ is the mantra of the supply chain being developed for next-generation commercial aircraft. Automation is evolving to meet the challenge.

Read More2019 Paris Air Show: Highlights

The 2019 Paris Air Show may have lacked the glamour of a new aircraft program announcement, but the composites industry represented is clearly gearing up for next-generation aerospace manufacturing.

WatchSpirit AeroSystems debuts next-generation composite fuselage panel

The 18-by-12-foot (5.5-by-3.7-meter) demonstrator panel debuted at the Paris Air Show features integrated skin and stringers and offers substantial cost savings combined with strong performance attributes.

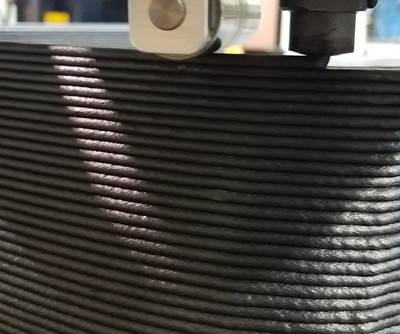

Read MoreBig additive machines tackle large molds

In commercial aerocomposites fabrication, molds reign supreme, but they are expensive. Large-format additive manufacturing systems are poised to make production-ready molds quickly and affordably.

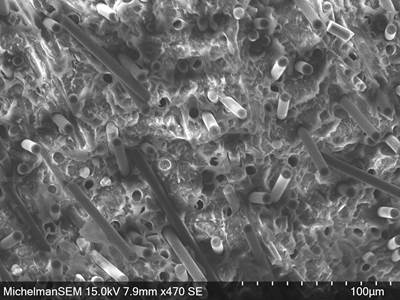

Read MoreFiber sizing, tow spreading and the quest for encapsulation

Fiber sizing is easily overlooked by composites fabricators, but it will be increasingly important to optimization of fiber performance.

Read MoreSpirit AeroSystems invests in qualification program with Toray prepreg

The world’s largest aerospace tier supplier seizes the opportunity to develop its own allowables for a carbon fiber prepreg, setting an important precedent.

Read MoreSAMPE 2019: The highlights

CompositesWorld was at SAMPE 2019 and offers a summary of highlights from the show and conference.

Read MoreLarge, high-volume, infused composite structures on the aerospace horizon

Infused carbon fiber composite structures are not new, but they have never been built at the rates anticipated for next-generation, single-aisle aircraft. It is a daunting prospect — but a feasible one.

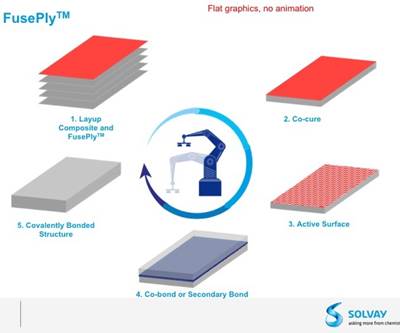

Read MoreSolvay epoxy-based film for prepregs

Solvay Composite Materials has developed FusePly, an epoxy-based film that is designed to co-cure with a prepreg and provide a chemically active surface that reacts with functional groups in adhesives to create a covalently bonded structure.

Read More