Spirit AeroSystems invests in qualification program with Toray prepreg

The world’s largest aerospace tier supplier seizes the opportunity to develop its own allowables for a carbon fiber prepreg, setting an important precedent.

Qualification of composite materials — particularly prepregs for aerospace applications — traditionally has been so time-consuming and expensive that its funding usually comes from one of the aerospace primes (Boeing or Airbus) or an independent laboratory, such as the National Institute for Aviation Research (NIAR) at Wichita State University (Wichita, Kan., U.S.).

When a prime funds a material qualification, allowables are usually developed for a specific application, but this can restrict or hinder the utility of the data beyond the application for which it was developed. A lab, such as NIAR, using the NCAMP process, can build an approved test plan followed by the appropriate specifications and test reports to deliver material allowables that are useful and helpful to the aviation industry. However, lacking infinite resources, NIAR cannot qualify every prepreg brought to market. This causes the industry to pick and choose the most significant material systems for NCAMP inclusion, though these may not always cover all needs of the aviation industry partners, which range from large OEMs to smaller suppliers.

Spirit AeroSystems (Wichita), the world’s largest Tier 1 aerospace supplier, and arguably the world’s largest fabricator of aerospace composites, has followed these traditional models like the rest of the composites world. It has been particularly tied to qualification data derived from its customers, which include Boeing, Airbus and other OEMs.

Chris Boshers, director of engineering, strategic programs, at Spirit AeroSystems, reviewed the materials market and recognized two years ago that the current models do not serve the entire aerospace composites market satisfactorily. In particular, says Boshers, there is a category of aircraft manufacturers that lack the resources to fund qualification efforts of their own, but that also find the available qualified materials through processes such as NCAMP fall short of their material qualification needs in terms of choices.

To fill this gap, says Boshers, Spirit AeroSystems decided to self-fund the qualification of a new prepreg, and in doing so, hopes to meet the needs of current and potential customers who cannot afford their own qualification programs. In the process, the company aims to begin building a new business niche. “We’re investing in something that we think can help our customers, suppliers and Spirit,” Bosher says.

The material Spirit has qualified is T1100/3960, an intermediate modulus aerospace prepreg manufactured by Toray Composites Materials (America ) (Tacoma, Wash., U.S.) and introduced to the market in 2017. Boshers says this prepreg was chosen because it offers 20 percent greater stiffness than its widely used predecessor — Toray’s T800S/3900 prepreg — but without any of the strength degradation that normally accompanies a boost in stiffness. This combination, says Boshers, makes the material particularly well-suited for next-generation aerostructures.

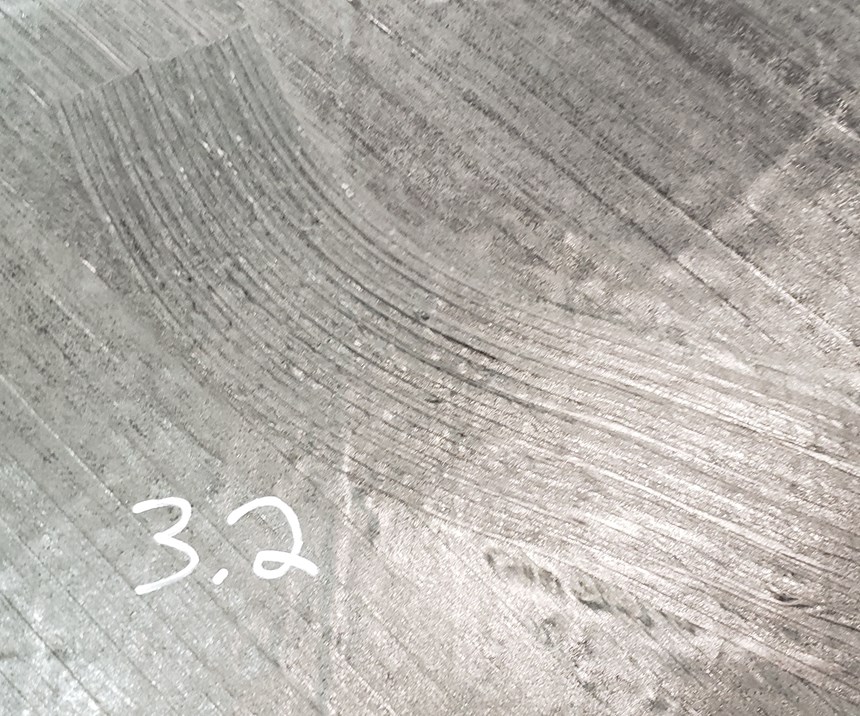

Spirit contracted with NIAR to do the qualification, which was conducted over the last two years. Boshers says Spirit evaluated producibility of the prepreg exclusively for automated fiber placement (AFP) processes; the allowables data does not cover hand layup at this time, but there is an equivalency test plan in the works to answer this question. Spirit, in the process of developing the allowables data, fabricated a large part that Boshers says demonstrates the capabilities of the material in a range of potential applications, including fuselage, wing and tail structures. Boshers singled out the T1100/3960’s easy steerability as a significant feature of the prepreg.

According to Eric Hein, senior director of R&T at Spirit AeroSystems, an investment in NCAMP to develop processes for qualification of future material systems that are designed for the manufacturing and deployment of tomorrow’s aircraft is essential — not only for the future of Spirit but the future of the aviation industry as a whole.

Jeff Cross, director, aerospace business development at Toray Composite Materials America Inc. (Tacoma, Wash., U.S.), says T1100G/3690 prepreg features a new fiber introduced by Toray in 2017. Toray’s T1100 family of fibers offers improved tensile and modulus strength properties as compared to legacy IM fibers, creating a new class of fiber called IM+. The fiber is manufactured in Toray’s Decatur, Ala., carbon fiber production facility; the T1100/3960 prepreg is produced in its Tacoma plant. As the name implies, it is designed to fill the modulus gap between intermediate modulus (IM) and high modulus (HM) fiber. Cross notes that Toray is aiming the prepreg toward high-performance applications, including vertical lift airframes and rotor components, space launch vehicles and weight-critical defense platforms. Cross says the material’s increased modulus can provide advantages to designers of next-generation commercial airfoils who desire minimum thickness cord sections and longer wingspans.

T1100/3960 offers tensile strength of 3,797 MPa, tensile modulus of 173 GPa, compressive strength of 1599 MPa, compressive modulus of 151 GPa and an in-plane shear strength (at ultimate) of 93 MPa. Click here to access all materials data for T1100/3960.

The Next Generation of Aerospace Manufacturing

With the commercial aviation industry projected to double in the next 20 years, meeting the demand for passenger and freight aircraft will require new technologies and unprecedented manufacturing rates.

Learn more about the materials and processes that will shape next-generation aircraft in a collection of stories from CompositesWorld, Modern Machine Shop and Additive Manufacturing, available to read or download for free. Get it here.

Related Content

Recycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreThe lessons behind OceanGate

Carbon fiber composites faced much criticism in the wake of the OceanGate submersible accident. CW’s publisher Jeff Sloan explains that it’s not that simple.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More