Fiber sizing, tow spreading and the quest for encapsulation

Fiber sizing is easily overlooked by composites fabricators, but it will be increasingly important to optimization of fiber performance.

Whenever a composites manufacturer thinks about fabricating a part or structure, he or she, understandably, focuses on the basic, raw ingredients of a composite application: resin, fiber, tooling, processing, finishing. Absent from these considerations most of the time is fiber sizing — the chemistry applied to fibers to facilitate handling, minimize abrasion, promote resin/filament adhesion or convey some other property to the fiber to help optimize mechanical properties in the final part.

Sizing is easily overlooked because it is typically applied by the fiber manufacturer using chemistry that is often tightly controlled. Further, sizing is a material that is most noticeable by the handling, processing and performance headaches that arise in its absence. When it is present, on the other hand, it performs with rare recognition.

As resins and fibers evolve, however, sizing is likely to move closer to the top of the composites industry’s collective mind. Dr. Nagesh Potluri, group technology director at sizing specialist Michelman (Cincinnati, Ohio, U.S.), says the chemical and physical complexities surrounding fiber sizing should not be underestimated.

Michelman’s history is grounded primarily in development and manufacture of sizing for glass fibers reinforcing polypropylene (PP). The company also has sizings optimized for use with polyamide (PA) and polyurethane (PU) polymers. Potluri notes, however, that the company recognizes the aerospace industry’s tilt toward increased use of thermoplastic matrix resins, and sees an opportunity.

Continuous fibers used with aerospace thermoplastics, like PEKK, PAEK and PEEK, typically go unsized, mainly because high temperatures make sizing use challenging. Michelman, however, is working on technologies that will enable thermoplastic sizing.

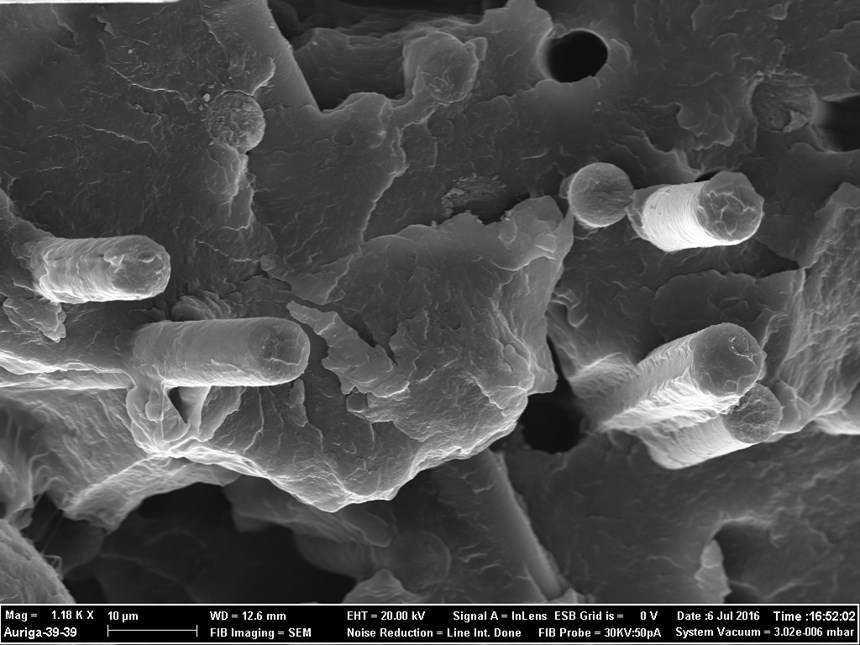

This work has led to another, related, area of interest: fiber spreading. Potluri notes that carbon fiber tows, whether being used to make unidirectional tapes or woven fabrics, must first be spread to flatten out and straighten the filaments. Generally speaking, carbon fibers of 3-12K tow are relatively easy to spread, while larger tows are more cumbersome and difficult to spread, primarily because of fiber-to-fiber friction, which can cause filament entanglement or breakage. Potluri argues that a well-spread tow facilitates more even sizing distribution, which, in turn, promotes better resin/fiber adhesion.

“The weakest link in a composite is the matrix,” Potluri says. “That’s why we like high fiber volumes. For this reason, you want the matrix to impregnate the interstitial spaces between fibers and maximize the mechanical properties embedded in the fibers. Effective spreading does that.”

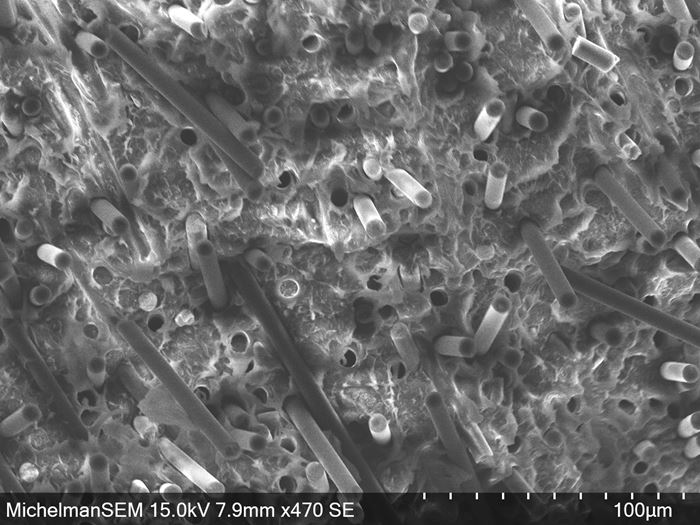

In a typical carbon fiber fabric, he says, just 60-70 percent of all filaments interact with, or are encapsulated by, the matrix resin. To increase this number, Michelman is working on a lubricant-based sizing that would be applied to a carbon fiber tow to minimize fiber-to-fiber friction and ease spreading, and by extension improve fiber/matrix distribution. “If we do that,” Potluri says, “we are essentially getting to theoretical maximum fiber performance values.”

The Next Generation of Aerospace Manufacturing

With the commercial aviation industry projected to double in the next 20 years, meeting the demand for passenger and freight aircraft will require new technologies and unprecedented manufacturing rates.

Learn more about the materials and processes that will shape next-generation aircraft in a collection of stories from CompositesWorld, Modern Machine Shop and Additive Manufacturing, available to read or download for free. Get it here.

Related Content

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreTU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

Read MoreJeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More