Another opportunity to meet, and learn, in Paris

At the JEC World 2017, improvements in materials and processes were present at nearly every stand, with the emphasis on automotive-capable production speeds.

This Audi R8 Coupe incorporates adhesive technology

Improvements in materials and processes were present at nearly every stand, with the emphasis on automotive-capable production speeds. And it was apparent that the composites industry is thriving, based not only on well-established suppliers but also on the number of new exhibitors, some with massive stands and clear vertical integration. One notable example was Kangde Composites Co. Ltd. (KDC, Beijing, China), who exhibited its vertically-integrated capabilities and value chain including carbon fiber, fabrics, prepregs, part manufacturing, design and research capabilities. ZAX Technology is KDC’s carbon fiber production plant with a reported annual carbon fiber capacity of 5100 tonnes (15,000 tonnes precursor capacity), located in Langfang, China, close to Beijing. The exhibit also included KDC carbon fabrics and prepregs, in multiple areal weights and weaves and resin types. Also represented was KDX Europe Composites R&D Center and KDX Roding Europe Automobile Design Centre (the latter located near Munich), involved with composite part design and research, for automotive and other applications. The group says it plans to build a huge “Industry 4.0” plant, with an annual capacity of 1.5 million CFRP parts.

Material advancements

A good example of new materials was found at the L&L Products Inc. (Romeo, MI, US and Molsheim Cedex, France) stand, which featured a new multi-material-capable, heat-activated, fast-cure, one-component, structural epoxy film adhesive, optimized for an induction welding process. The epoxy film, with an integral fiberglass veil, guarantees a correct bond line (from 0.1 to 0.4 mm) and the veil delivers galvanic protection between metals and composites, for inductively-welded small fasteners or larger components heated using other methods. The company says that at a bonding temperature of 190°C, complete cure is achieved in 45 seconds with 28 to 30 MPa lap shear performance. The company is working with automotive OEMs and Tier 1 suppliers. Similar applications are used in the Audi R8 Coupe chassis, which was on display at the SGL Technologies GmbH stand (Meitingen Bayern, Germany), but the advantage of the L&L Products adhesive compared to the current one is that the material can be stored at room temperature, says the company.

Also on the automotive front, Fraunhofer Institute for Chemical Technology (ICT, Pfinztal, Germany) and Sumitomo Bakelite Co. Ltd.’s (Tokyo, Japan) group company Vyncolit N.V. (Gent, Belgium) announced that they will collaborate on further development of functional and structural automotive parts using phenolic-based fiber composite materials. The companies note that in addition to cylinder housing and engine blocks, the high-performance molding compounds can be used in the drive train, to reduce weight, provide acoustic damping and offer better thermal performance. The materials also offer new design possibilities, not possible in aluminum. Sumitomo Bakelite’s recently-launched sbDRIVE initiative for the auto industry provides lightweight solutions, at acceptable cost, in the automotive powertrain, including design, material development, process development and prototyping, for large-series production, all of which will be in cooperation with Fraunhofer.

Sicomin Epoxy Systems (Châteauneuf les Martigues, France) announced that it has secured a significant bioresin supply agreement with Cobra International (Chonburi, Thailand), a customer for more than 25 years who is the largest OEM manufacturer in the world of watersport boards (surf, windsurf, and standup paddleboards), as well as a manufacturer of automotive composite parts. Cobra’s CEO Danu Chotikapanich told CW that when the company moved to its new facility in 2000, it committed to sustainability throughout its business. Sicomin’s Greenpoxy products “deliver the same performance as previous non-bio resins,” says Chotikapanich, and Cobra now makes 50% of its watersport products with Greenpoxy. Sicomin also launched InfuGreen 810, an epoxy infusion system that was recently awarded DNV GL certification. The new resin is formulated to support injection or infusion techniques, including very thick laminates, and is available in large quantities. It has a very low viscosity at room temperature, has a 38% plant-based bio content, and is available with a range of hardeners.

Chomarat (Le Cheylard, France) highlighted two new materials for the show. The first, G-FLOW 500L is a structural, 0/90 woven 100% glass fiber flow media intended for infusion processing. Its specific textile geometry allows faster resin flow, replacing an external or internal flow media material, and is reportedly 100 times more permeable than traditional reinforcements like non-crimp fabrics or woven roving. Because G-FLOW is a structural reinforcement, it stays in the laminate, saving the cost of the flow media material. Also on display was C-WEAVE design, an alternative to standard carbon fiber fabric. Made with 3K carbon fibers, it’s unique weave gives a subtle hexagonal pattern, which might be desirable in sports equipment or automotive panels. C-WEAVE design is also available in a carbon/Innegra fiber (30% of total weight) version, for sports equipment products where vibration damping is desired.

The Vision of the Fjords all-carbon composite catamaran includes DIAB core materials, SAERTEX reinforcements and Reichhold resin.

DIAB’s (Laholm, Sweden) innovative booth, with the theme “stronger, lighter, smarter,” showed visitors just how light cored composite panels can be compared to legacy metals by using demonstrator panels loaded with kettlebell weights. DIAB was one of the winners of the JEC Innovation Award in the “Better Living” category for the 40m-long all-carbon composite Seasight catamaran, Vision of the Fjords, built by Brødrene AA AS (Hyen, Norway). DIAB (Laholm, Sweden) supplied the core material for the sandwich laminates, SAERTEX supplied the carbon fabric reinforcements, and Reichhold (Research Triangle Park, NC, US) the vinyl ester resin for the fast-tracked project. The vessel, powered by hybrid-electric motors, is vacuum infused, and the carbon design is 50% lighter than legacy materials (and thus uses less fuel to operate, a key project goal). Vision of the Fjords is used for tourist excursions in the UNESCO World Heritage-listed fjord of Nærøyfjord. Also on display at the stand: a new “microcell” polyvinyl chloride (PVC) core, H60MC, with cell size one-fifth that of normal PVC. The smaller cell size reduces the total resin uptake per square meter by 80% during processing, allowing for substantial weight and cost savings, says the company.

Coats Industrial (Uxbridge, UK), the world’s largest producer of sewing thread, exhibited its Synergex range of advanced composite carbon fibers used in custom solutions for a range of markets including automotive. Coats produces unidirectional tapes, as well as a range of fabric weaves, braids and tailored fiber placement. The company’s commingled carbon and thermoplastic yarn is used to produce, through tailored fiber stitching of flat preforms, the wheel arches for the Elemental Rp1 production sports car, which was on display at the Coats stand.

The Elemental Rp1 sports car incorporates carbon fiber technology from Coats.

Aerospace innovations

Aerospace innovations were reflected as well, particularly the main rotor hub of the composites-intensive Airbus H160 medium-duty, twin-engine helicopter, on display at the Porcher Industries (Eclose-Badinieres, France) stand. The new Spheriflex composite hub is a carbon fiber-reinforced polyetheretherketone (PEEK) part, with high toughness and fatigue resistance, resistance to aviation fluids, and end-of-life recyclability, and it reportedly delivers three times the life span of legacy metal or thermoset composite materials. Porcher’s CEO André Genton told CW that the company developed, with Airbus, new carbon fiber reinforced plastic (CFRP) prepreg tapes with controlled fiber sizing, along with a special weaving and high-temperature impregnation process. The part, which undergoes tremendous flexion during operation, has passed rigorous testing and has received the go-ahead for production by Airbus Helicopters.

The Airbus H160 main rotor hub made with carbon/PEEK materials from Porcher

Henkel AG & Co. (Duesseldorf, Germany) presented a technical paper on an improved liquid shim for aerospace manufacturing, EA 9378 Aero, an epoxy-based structural liquid shim system with better performance. The shim, which fills gaps between parts during assembly while supporting fasteners, has a 33% faster cure rate than legacy shim materials (for shorter drill time), exhibits very low shrinkage and shows improved performance and durability in fatique tests over a wide range of thicknesses, without visible cracks. Also on display: Henkel’s Loctite EA9845 LC AERO aerospace surfacing film with lightning strike protection that can help reduce aircraft weight due to its lower thickness and which provides excellent surface finish. Textron Aviation Inc. (Wichita, KS, US) just announced that it has selected the film for its composite components.

Evonik Industries (Darmstadt, Germany) had a busy stand with multiple exhibits, among them the announcement that the company’s ROHACELL HERO polymethacrylimide (PMI) foam is now qualified by Airbus for aircraft structural parts (under AIMS 04-11-011 and ABS5955 standards), passing required bird strike impact tests. HERO foam was developed to replace honeycomb cores in aircraft structure, but with significantly reduced layup times, weight savings and cost reductions, says the company.

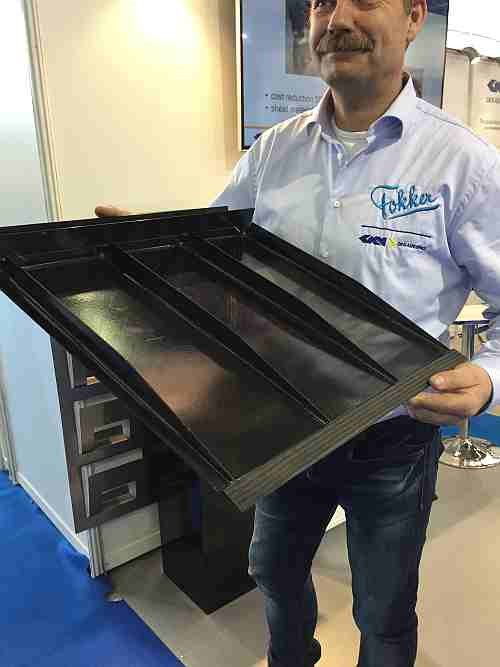

A thermoplastic composite aileron demonstrator on display at Fokker Aerostructures.

At the Fokker Aerostructures (Papendrecht, Netherlands and Hoogeveen, Netherlands) stand, collocated with parent company GKN Aerospace (Redditch, Worchestershire, UK), a technology demonstrator carbon fiber/thermoplastic aileron part was on display, consisting of two halves welded together. Each half is a skin with co-consolidated stiffeners and a half-height spar; stiffeners and spar are flat parts that are butt joined to each other and the skin, a process possible due to the thermoplastic matrix. The final triangular “box” part shape is created by welding at the trailing edge and the spar, says Arnt Offringa, Fokker Aerostructures director of R&D.

Machine tools and processing

A significant portion of the exhibits space was devoted to machine tool and process equipment manufacturers. MTorres Diseños Industriales SAU (Torres de Elorz, Spain), known for its automated fiber placement (AFP) and automated tape laying (ATL) machines, discussed with CW that its hybrid ATL/AFP machines, which accept both 24-tow, ½-inch AFP end-effectors and ATL head end effectors, are capable of head changes in less than 2 minutes. The AFP end-effector is designed to contain high-weight spools, up to 9 kg, reducing times between head changes. These hybrid machines have reportedly saved 30 million Euro for Airbus at its Stade and Illescas plants, as evidenced by a recent internal Airbus award. Also on display were MTorres’ new, highly flexible robotic ATL and AFP systems, for carbon fiber composite part fabrication (and reportedly already in use in aerospace production); the system was shown in an MTorres video at the show. MTorres will be exhibiting at the upcoming Paris Air Show, where some composites-related announcements are expected.

Cannon SpA (Borromeo, Italy) had a busy stand featuring the company’s wide range of machinery and solutions for composites processing, including prepreg compression molding, liquid compression molding, preforming, high-pressure RTM, SMC and GMT molding, dispensing machines for wind blade manufacture and more. Notable was information on Industry 4.0, and Cannon Group company Cannon Automata’s cybernetic solution and digital communication system for smart factories. Automata provides solutions both internally for the Cannon Group as well as for outside companies.

Along the lines of Industry 4.0, Diversified Machine Systems (DMS, Colorado Springs, CO, US), maker of custom CNC cutting machines and turnkey manufacturing solutions, emphasized its ability to improve composites manufacturing. It works with software provider CIMCO A/S (Copenhagen, Denmark), whose manufacturing data management system (MDM) allows DMS customers to manage project data, including CAD/CAM files, NC programs, tool lists, setup sheets and much more, on a central server. CIMCO integrates seamlessly with CAD/CAM systems from many vendors, as well as with other machines in the customer’s production line. DMS emphasized their expertise in custom machine designs to accommodate specific customer process requirements re: efficient production.

Zünd (Altstätten, Switzerland) demonstrated its G3 M-1600 modular cutting table, able to handle anything from prepreg (thermoset or preconsolidated thermoplastic sheet) to dry fabrics and core materials, together with a “collaborative” robot arm supplied by Universal Robot (Odense, Denmark) for offloading. With its modular design, customers can install different tools, or add modules such as an inkjet printer, and can be integrated into a fully-automated industrial production setting. The robust, upgradable design and open -source interface command system (Zünd Cut Center) reduces customer risk, says the company. The collaborative robot does not require caging or protective workspace and can offload cut materials and kits to relieve workers from repetitive motion.

Gunnar AG (Rebstein, Switzerland) exhibited a static cutting table, the Aiox, designed for the small shop that wants to eliminate hand cutting, but doesn’t require a full automated setup. With a vacuum system to hold materials in place, the 1.2 by 1.6m Aiox runs on 110V electrical and employs a knife system (drag knife or “pizza” wheel). Multiple software control modules are available, depending on customer needs, and the machine can be upgraded with various hardware modules (nesting, or inkjet printing, for example) or robotic off-loading.

Evonik also displayed its PulPress technology, a new manufacturing method that combines pultrusion and a press system for shaped structural parts. A Rohacell foam core is automatically encased in fiber reinforcement and resin, then fed into a moving press that processes the part at elevated pressure and temperature. The resulting 3D profile can be shaped and inserts and fasteners can be included. The high production speed processes reportedly delivers parts with virtually no waste, and is significantly less expensive than a process such as RTM, says the company, and is intended to replace metallic parts in aerospace and automotive applications.

Owens Corning exhibited a composite rebar cage used to reinforce precast tunnel segments at its stand. The company sees significant growth in infrastructure applications for composites.

More focus on recycling

Recycling of composites was more evident at the show, and some significant announcements took place regarding composite waste recycling and reuse. ELG Carbon Fibre Ltd. (Coseley, Dudley, UK) revealed it is providing recycled carbon fiber for a semi-structural automotive car part being produced by Tier 1 supplier Sanko Gosei (Skelmersdale, UK), using reinforced thermoplastic compounds from Albis (Knutsford, UK). The objective is to demonstrate the feasibility of using recycled fibers in production automotive applications.

ELG's JEC stand

Following up on its strategic investment in Carbon Conversions Inc. (CCI, Lake City, SC, US) last December, Hexcel (Stamford, CT, US) showed CCI’s recycled carbon fiber products at its stand, including nonwoven mats from 100 to 500 gsm in weight, high-loft, 1200 to 1400 gsm products made with CCI’s 3-DEP water-based slurry process, and non-woven commingled hybrid blends.

CRTC (Composite Recycling Technology Center, Port Angeles, WA, US), with a stand in the US Pavilion, showed its latest product made with the group’s repurposed prepreg production waste: pickleball paddles. The non-profit group, focused on driving economic development in the region while growing recycling methods, reuses near-first-quality carbon/epoxy prepreg scrap to make products. It recently announced a memorandum of understanding (MOU) with ELG Carbon Fibre to use ELG products as well, in new products, as the group expands through many ongoing partnerships and collaborations. The pickleball paddles are the first of many products to come; the paddles have been endorsed by the USAPA and are distributed by Pickleball Central of Kent, WA, US.

Adesso Advanced Materials (Wuhu, China and Monmouth Junction, NJ, US), which offers a recyclable thermoset resin technology called Recycloset, is also involved in an automotive project, partnered with ELG and with Chery New Energy Automobile Technology Co. Ltd. (Wuhu, China). Adesso’s Recycloset resin will be combined with ELG’s recycled carbon in the Chery eQ1 electric vehicle, to replace aluminum. The group’s chairman and CEO revealed that Adesso will cooperate on the development of recyclable wind turbine blade resin formulation with the University of Southern California and Dr. Steve Nutt.

French technology transfer and research group Cetim-Cermat (Mulhouse-Cedex, France) unveiled a new composite recycling pilot line for direct production of composite structural panels from thermoplastic composite waste. And, a press conference was held on Wednesday at the show, by Innovation Plasturgie Composites (IPC, Bellignat-Oyonnax Cedex, France) in collaboration with CRECOF, the French composite recycling collective, to launch the first guide to composites recycling. The guide was co-financed by IPC and the French government agency ADEME to provide information for manufacturers working with composites on recycling technologies and applications for recycled material.

Related Content

JEC World 2023 highlights: Recyclable resins, renewable energy solutions, award-winning automotive

CW technical editor Hannah Mason recaps some of the technology on display at JEC World, including natural, bio-based or recyclable materials solutions, innovative automotive and renewable energy components and more.

Read MoreRTM, dry braided fabric enable faster, cost-effective manufacture for hydrokinetic turbine components

Switching from prepreg to RTM led to significant time and cost savings for the manufacture of fiberglass struts and complex carbon fiber composite foils that power ORPC’s RivGen systems.

Read MoreComposites end markets: Batteries and fuel cells (2024)

As the number of battery and fuel cell electric vehicles (EVs) grows, so do the opportunities for composites in battery enclosures and components for fuel cells.

Read MoreCollins Aerospace to lead COCOLIH2T project

Project for thermoplastic composite liquid hydrogen tanks aims for two demonstrators and TRL 4 by 2025.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More