Consumer electronics: hybrid composite covers

Study demonstrates feasibility of thermoplastic composites, high-speed production process.

SABIC demonstrated in a recent study that a 1-millimeter thick cover could meet all relevant industry performance specifications for very thin notebook computers or tablets. Source, all images | SABIC

Consumer electronics is a dynamic market with quite short cycle times between product generations. From their smartphones, smartwatches, tablets and notebooks/laptops, consumers want faster operating speeds, longer-lasting batteries, greater durability and more features at lower cost and weight. To meet consumer demand, OEMs ask suppliers for materials with high aesthetics and design freedom, excellent impact resistance and high stiffness — which connotes quality in this market — at low weight and thin wall sections. They also want cost-effective, highly repeatable processing methods that meet global production demand in the tens-of-millions of units annually. These pressures have pushed the market first to lightweight metals for covers/cases and frames, and now is driving it toward metal/composite and fully composite solutions.

A feasibility study conducted by SABIC (Bergen op Zoom, Netherlands) involved use of two types of thermoplastic composites to produce a 1-millimeter-thick notebook-computer/tablet cover. The study showed the hybrid thermoplastic composite design could be a viable solution for the challenging consumer electronics market.

Test case

Since 2012, SABIC has made a series of investments to develop its own unidirectional (UD)-fiber-reinforced thermoplastic composite tapes (see “Evolving into continuous fiber reinforcements”), which extended the company’s core competency in short-fiber injection and long-fiber thermoplastic (LFT) materials, and allowed SABIC to expand into higher performance thermoplastic composites. In 2015, the company purchased majority share in tape maker Fiber Reinforced Thermoplastics B.V. (FRT, Lelystad, Netherlands) and in 2017 it partnered with and became a minority investor in Airborne (The Hague, Netherlands), a machine maker and developer of composite processing lines.

As SABIC and Airborne designed and built technology to rapidly and cost effectively produce net-shape, high-quality thermoplastic tape-based laminates for truly high-volume markets (see “High-speed, high-rate thermoplastic composites manufacturing”), the team began looking for a test case. This demonstrator would be an important marketing tool to prove out design concepts for thermoplastic composite laminates produced from composite tapes overmolded with discontinuous fiber-reinforced compounds. It also would be important to test predictive engineering tools the team had developed for both materials technologies and to showcase the high-speed manufacturing process evolving in the Netherlands.

“We decided to specialize in consumer electronics applications,” explains Gino Francato, SABIC global composites leader. “That market is very interesting because there is a real ambition to move into lightweight materials to make our mobile phones and notebooks lighter and thinner. And since they make millions and millions of them, we decided to take the challenge this market offered.”

“We decided to start with something that was reasonably complex but not too complex,” explains Scott Davis, SABIC staff scientist-global application technology. The top cover of a very thin notebook computer or even a tablet — which the team hoped would eventually translate to smartphone components — seemed a good place to start. “We were working with a simple overall geometry, a rectangle, that still had to maintain high aesthetics and offer lots of complexity on its B-side, including attachment features,” continues Davis. “We had to keep the cover very thin, but still meet challenging deflection requirements common in the industry. And, of course, we had to deliver a very consistent product via a complex new manufacturing process.”

Since they weren’t working with an actual customer design, and were only creating the protective cover for a screen, they used generic geometry. In fact, Davis notes, when they started cutting injection tooling for internal development, they weren’t even sure if they would be making a tablet or a notebook cover, so the cover was designed to work for either. “There were lots of challenges to get a composite solution ready for high-volume production,” Davis adds. “In fact, there was a lot happening simultaneously — tape development, laminate development and process development — and we couldn’t wait until all those things were finalized to begin our tooling, which is how we ended up with that design.” With basic design complete, the team focused on other details, such as the best way to gate, what kinds of overlaps were needed between laminate insert and overmolding compound, how to handle automated placement inside the tool, how to deal with the coefficient of (linear) thermal expansion (CLTE or CTE) mismatch between the two composites and how to create an easily repeatable part.

Meeting challenging requirements

The goal was to develop a 1-millimeter-thick upper cover that provides high stiffness and passes all performance and aesthetic requirements — especially the center-point deflection test applied regularly to laptop covers to evaluate the loads required to damage the underlying screen. Load/deflection requirements vary by OEM, device and model, but typically no more than 3-5 millimeters of deflection are allowed under 40-120 Newtons of pressure — a situation that simulates the loads exerted by a finger or elbow pressed into the cover as a human user stands up. In many industries, the strategy for passing such tests would be to increase section thickness, but this market values thinner designs that free up space for larger batteries and other components without increasing device size or weight. Hence, the team needed to use a different design strategy to prevent screen damage — namely selecting stiffer materials (via a laminate insert) and using geometry (for example, ribbing via injection overmolding). But, first, they had to specify materials.

One of these materials, polycarbonate (PC), is already widely used in this industry for covers and other components, owing to its excellent aesthetics and high impact strength. The polymer’s biggest weaknesses are chemical resistance and surface scratching, but the coating, paint or combinations of both applied to most covers generally overcome these potential problems.

“Because ultralight computers are so thin, package space inside is at a real premium, so deflections and mechanicals become really critical,” Francato points out. “While you would want to use glass [reinforcement] from a cost perspective, we had to use carbon [fiber] to get the stiffness we needed.” As a result, all tape-based laminates evaluated were variations of carbon fiber-reinforced polycarbonate — grades then under development with SABIC subsidiary FRT.

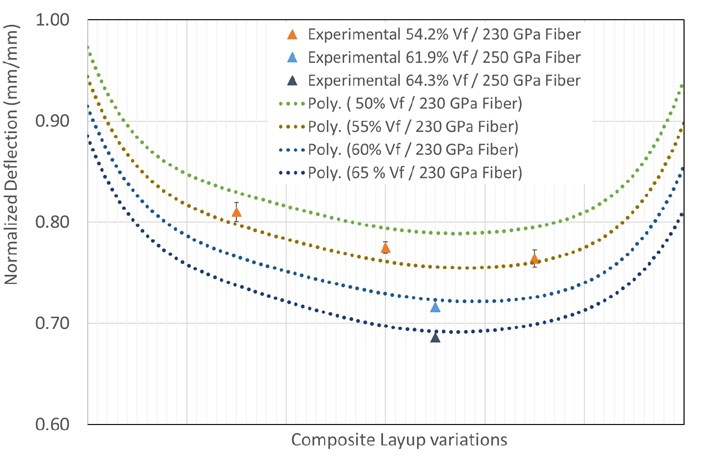

SABIC has developed predictive models to simulate laminate type and architecture (with and without overmolding compounds) vs. molded part performance and reports strong correlation between predictions and experimental results have been achieved. The predictive engineering tools are said to accelerate material development.

The overmolding compound required a different approach. Initially, the strategy was to use a longer-fiber LFT compound, but for a number of reasons — including high aesthetic requirements, part size and gating strategy — short-fiber compounds better met project requirements. Another issue was the type of fiber to use. “Short-carbon injection compounds are really difficult to work with and still get high aesthetics,” continues Francato, “so for our overmolding material, we looked at short-glass-reinforced grades.” SABIC subsidiary LNP Engineering Plastics, Inc. (Exton, Pa., U.S.) offers many glass fiber/PC grades with good aesthetics and stiffness that are popular among device OEMs, so the team focused on those.

While fully amorphous PC is less prone to warpage than semi-crystalline polymers, still the team worried about CLTE differences between the highly reinforced and anisotropic UD carbon fiber tapes and the more isotropic, discontinuous short-glass fiber overmolding grades at lower fiber loadings. “In such thin walls, there’s very little room for error, so the slight differences in CLT were things we had to carefully consider,” explains Davis. “And that doesn’t even touch on all the normal issues you’re concerned with when injection molding, like gate locations, fill patterns, packing pressures and knitlines. All these factors were simulated and verified with physical testing.”

Once the materials were chosen, SABIC engineers conducted multiple iterations of mold filling, structural analysis and warpage simulation to evaluate laminate layup, geometry and materials combinations to optimize stiffness for the load/deflection test, plus other performance and cost requirements. The company says it has developed comprehensive and accurate composites modeling tools (available to customers and running in common structural and processing codes) that can rapidly model and simulate laminate architecture, overmolding compound composition and various processing and tooling options versus as-molded part performance. These tools are said to achieve strong correlation between predictions and measured performance and are ideal for accelerating custom materials development.

Ready for prime time

Front side of the final laptop/tablet cover, which was produced using a carbon fiber-reinforced polycarbonate tape-based laminate insert overmolded with short-glass/polycarbonate-copolymer compound, a combination that met all relevant mechanical and aesthetic requirements in a 1-millimeter thick part.

The final demonstrator features a laminate insert produced from seven layers of developmental UDMAX carbon fiber/PC tapes (55% fiber volume fraction), then consolidated, trimmed, preformed and trimmed again to final net-shape, before being injection overmolded with 40% fiber-weight fraction THERMOCOMP D452 short-glass fiber/PC-copolymer (a grade optimized for high flow and high aesthetics and already widely used in this segment). The combination produces a cover with high stiffness and strength at low mass and section thickness while including numerous 3D design details, attachment features and good aesthetics, thereby harnessing the best of each material. The cover reportedly passed all requisite industry tests and currently is being evaluated by device OEMs.

Back side of the finished cover.

Work between Airborne and SABIC also has borne fruit for SABIC’s consumer electronics market goals. The partnership was announced in 2018, and this year further detail has been provided about what both companies call their Digital Composites Manufacturing Line, which can produce four net-shape consolidated laminate inserts from thermoplastic composite tapes per minute or 1.5-million laminates per year from a single production line. The system is said to be flexible (in terms of layup architecture and materials) and fast. Beginning in 2020, Airborne will use the line to manufacture laminates for commercial use in consumer electronics, becoming a resource that both companies hope will greatly increase penetration of thermoplastic composites in this highly competitive and fast-paced segment.

Related Content

Carbon Mobile, SABIC to develop, deploy advanced carbon fiber in connected devices

Collaboration aims to deliver the next generation of thinner, lighter, stronger and more sustainable composite materials used in consumer electronics and automotive industries.

Read MoreComposites end markets: Electronics (2024)

Increasingly, prototype and production-ready smart devices featuring thermoplastic composite cases and other components provide lightweight, optimized sustainable alternatives to metal.

Read MoreTeijin lightweight materials enable VAIO portable displays

Teijin's Tenax TPCL and Panlite Sheet materials allow for the creation of complex, three-dimensional shapes in a single molding step.

Read MoreSyensqo launches Swyft-Ply brand for electronics, smart devices

Multifunctional composites leverage traditional advanced material benefits while meeting specific industry manufacturing and performance requirements.

Read MoreRead Next

Evolving into continuous fiber reinforcements

SABIC expanded its materials offerings in short-fiber injection and long-fiber thermoplastic (LFT) materials to include continuous-fiber thermoplastic tapes.

Read MoreHigh-speed, high-rate thermoplastic composites manufacturing

A novel process from SABIC and Airborne promises high-speed, high-rate production of thermoplastic composite laminates for mainstream manufacturing and a variety of applications.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More

.jpg;width=70;height=70;mode=crop)