January Editorial

I trust that all of you had an enjoyable Christmas break. We took the opportunity here to do some end-of-year cleaning out and sprucing up, and also to reflect on the past year and our 2005 accomplishments here at Ray Publishing. One of our biggest was the launch of our e-newsletter, CompositesWorld Weekly. It gives

I trust that all of you had an enjoyable Christmas break. We took the opportunity here to do some end-of-year cleaning out and sprucing up, and also to reflect on the past year and our 2005 accomplishments here at Ray Publishing. One of our biggest was the launch of our e-newsletter, CompositesWorld Weekly. It gives us a chance to report on fast-breaking news and items of interest that we don't always seem to have room for in the magazine. Many of you have told us that you enjoy receiving the newsletter and get a lot out of it - thanks for your comments.

We also published another Guide this past year -- Composites in Alternative Energy - A design and application guide. It's the fifth in a series of similar guides that explain how composites play an enabling role in both established and emerging markets. The Guide is available for sale ($59.99) and you can order one by sending a message to guides@compositesworld.com; the address is also listed on the "Guides" page at our Web site. You might also have noticed that our Web site is bigger and faster than ever. Articles are available to read online and you can print them at no charge. You can also locate a comprehensive listing of suppliers to the industry in our fully-searchable, online SourceBook directory, which just went "live" last week for 2006. If you are a supplier anywhere in the world, and you don't see your company listed, call us to post your free listing. Our Webmaster will continue to optimize our site and make it more useful for both our advertisers and our readers.

After my comments throughout last year about carbon fiber supply shortages and the need for more supply capacity, it's encouraging to see that virtually all of the carbon fiber manufacturers are adding new lines (see our News story, page 13, and D.J. DeLong's Market Trends column on page 7). Plus, the Accordis precursor plant has been purchased by investors and will continue to provide commercial grade PAN precursor. It's also good to see that despite a tight fiber supply, manufacturers are confidently moving ahead with some innovative designs, like those featured in this issue. A surprising number of companies are planning to offer Very Light Jet models (page 34), small jet-powered planes that just might give commercial air carriers some heartburn if proposed air taxi networks become a reality. Some are producing all-composite aircraft supplied by pre-qualified AGATE prepregs, which proves the success of the FAA program that ended several years ago to streamline general aviation material qualification. On the subject of making material qualification easier, the article on microtesting (page 18) highlights how focused microscopic-scale tests can greatly simplify and reduce macro-scale material coupon and article testing. High-volume automotive and recreational apps are also featured -- our Inside Manufacturing story (page 24) features an innovative automated preforming method in which a "tailored blank" is made with carbon/thermoplastic tapes, for thermoforming of automotive parts (we got a chance to tour the facility and see the process first hand). And our bicycle design story on page 44 shows how carbon fiber is being put to use where it makes the most sense, for performance and cost-effectiveness.

So what so we plan to accomplish in 2006? We intend to update our Automotive Composites guide and reissue it with new information, so watch for that. Suppliers take note: if you're interested in supporting this effort, give me a call. We'll also strive to broaden our composites coverage, making our publications even more international. Have a safe and prosperous New Year!

Related Content

Plant tour: BeSpline/Addcomp, Sherbrooke, QC, Canada

Composites automation specialist increases access to next-gen technologies, including novel AFP systems and unique 3D parts using adaptive molds.

Read MoreNovel dry tape for liquid molded composites

MTorres seeks to enable next-gen aircraft and open new markets for composites with low-cost, high-permeability tapes and versatile, high-speed production lines.

Read MoreLarge-format 3D printing enables toolless, rapid production for AUVs

Dive Technologies started by 3D printing prototypes of its composite autonomous underwater vehicles, but AM became the solution for customizable, toolless production.

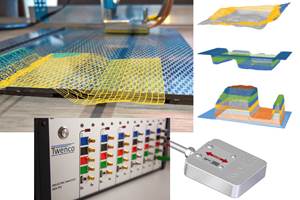

Read MoreTwenco develops sensors for smart molds and process control in resin infusion and composites welding

Non-invasive DEA and NDT Analyzer for multi-parameter monitoring, QA and control, including real time simulation feed and 3D process visualization across and through composite parts.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MorePlant tour: Teijin Carbon America Inc., Greenwood, S.C., U.S.

In 2018, Teijin broke ground on a facility that is reportedly the largest capacity carbon fiber line currently in existence. The line has been fully functional for nearly two years and has plenty of room for expansion.

Read MoreThe next-generation single-aisle: Implications for the composites industry

While the world continues to wait for new single-aisle program announcements from Airbus and Boeing, it’s clear composites will play a role in their fabrication. But in what ways, and what capacity?

Read More

.jpg;maxWidth=300;quality=90)