European boatbuilders lead quest to build recyclable composite boats

Marine industry constituents are looking to take composite use one step further with the production of tough and recyclable recreational boats. Some are using new infusible thermoplastic resins.

Share

Balsa core is laid up into the hull of Innovation Yachts’ 2023 Ocean Tribute Award-winning LBV35 catamaran.The reinforcement is volcanic fiber (i.e., basalt), the matrix a room temperature-cured, bio-derived epoxy. Photo Credit: Innovation Yachts/Marion Koch

The marine industry has long been at the center of engineering composites materials, methods and workforce development. As advanced composites have evolved, many industries have benefited from research done for the sake of competitive sport, the America’s Cup in particular. Where materials have been adapted from other industries, race boats have provided a proving ground by fatiguing material combinations in real-world corrosive environments. Strain gauges and failure analysis have become part of high-end race programs, and new processes are sometimes developed.

An increasing awareness of boats’ environmental impact makes today’s marine industry fertile ground for the testing and refinement of new materials designed for recovery and reuse (circularity). Other end-of-life (EOL) strategies are being pursued as well, such as the use of flax fiber that will ultimately biodegrade. As other industries increasingly embrace composites, boats and the molds used to produce them could also become a market for recycled materials.

Every year, CW publishes online articles devoted to the outlook of several composites-related end markets including “Composite end markets: Boatbuilding and marine,” a broad synopsis that reviews new developments in marine that were reported that year. This article specifically examines material suppliers and boatbuilders that are early purveyors and adopters of infusible, semi-thermoplastic resins, as well as a builder who is combining a novel reinforcement with bio-epoxy while developing their own methods for the recovery and reuse of composite materials.

Lalou Roucayrol and Arkema Elium

Arkema (Colombes, France) is reported to be first-to-market with an infusible thermoplastic recyclable resin, Elium. Custom boatbuilder and experienced offshore sailor Lalou Roucayrol of Neo Sailing Technologies (formerly Lalou Multi, Talais, France) led the prototyping effort and has been the face of Arkema Racing’s high-profile rollout. His protégé, Quentin Vlamynck, led the Ocean Fifty division across the Atlantic in the single-handed 2022 Route du Rhum: Destination Guadeloupe, race sailing the 50-foot trimaran Arkema 4. Though Vlamynck was deprived of first place by 18 minutes, the boat’s performance generated significant interest. With the boat renamed Solidaires en Peloton, Vlamynck remained a top competitor in 2023.

Although Arkema 4 was not entirely made using Elium, interesting use was made of the ability to recycle and reuse the resin. Notably, the molds for the floats (amas) were made from fiber-reinforced Elium and were then recycled and the resin reused to build parts of the boat’s deck, canopy and fairings. The first boat built using Elium was Arkema 3, a foiling monohull built by the same team prior to Arkema 4 to compete in the Mini 6.50 Proto Class.

The future of Elium use in volume yacht production may turn on its adoption by Arkema partners and major boatbuilding players Beneteau Group (Croix de Vie, France) with support from custom builder MultiPlast (Vannes Bretagne, France) and Brunswick Corp. (Mettawa, Ill., U.S.), with its several brands including Boston Whaler. A smaller startup, Northern Light Composites (Monfalcone, Italy), utilizes Elium across its sailboat line encompassing the Ecoracer25, the Ecoracer30 and the EcoFoiler. The 30-foot Ecoracer30 uses a combination of virgin and recycled carbon fibers, as well as flax fibers, adding to its sustainability focus.

Arkema business manager Nicolas Valloir, working in the Americas, explains that Brunswick Corp. has set some demanding targets and that Arkema’s joint R&D with them is ongoing. Valloir is less connected to the Benateau Group effort, but says that its First 44e has been well received and that other Elium models are in development. Arkema has been working with Merritt Precision (Merritt Island, Fla., U.S.), a Correct Craft company, on Elium molds. In Canada, Arkema has also recently participated in infusing a 45 footer, the largest Elium boat to date.

Elium is comprised of a thermoplastic acrylate copolymer cured by reacting monomers and oligomers of methyl methacrylate (MMA), an unsaturated ester, to become a poly (methyl methacrylate) (PMMA). As with unsaturated polyester and vinyl ester resins, a peroxide initiates the reaction. Elium also contains a base promoter, tributylamine or an iron salt, but does not contain cobalt, styrene or bisphenol A (BPA), making it less harmful to humans and the environment.1 Elium became “commercially available” in the fourth quarter of 2023. A sprayable version is available in Europe, though Arkema is also still assessing this option.

While boatbuilders may not have much experience with acrylic resins, many work with methacrylate adhesives such as Plexus (ITW Performance Polymers, Danvers, Mass., U.S.) or those from Arkema’s Bostik division. Boatbuilders also frequently work with clear acrylic sheet for portlights and other windows, windscreens and hatches. Those with non-marine construction experience may have come across acrylic products from EPS (Marengo, Ill., U.S.), including the emulsion PMMA resin Forton used to toughen glass fiber-reinforced gypsum (GFRG) panels. A lower toxicity than alternative aromatic resins makes these products more pleasant to work with — and likely safer.

Like unsaturated polyester, Elium resin cures at room temperature. Being a thermoplastic, Elium’s relative ductility gives it epoxy-like characteristics, enabling reinforcement fibers to take intermittent loads without fatiguing and ultimately cracking the matrix. Unlike many epoxies, no post-cure heat is necessary for Elium to achieve its full mechanical properties.

Part of an exclusive partnership with Arkema, Beneteau Group’s new eco-friendly boat concept, the First 44e, was made entirely from Elium resin and is the first such offering from a major production sailboat builder. Photo credit: Benateau Group

What makes a polymer thermoplastic is a discernable melting temperature (Tm) between its glass transition temperature (Tg) and its degradation temperature (Td). “Malleable and Recyclable Thermosets: The Next Generation of Plastics,” a 2019 University of Colorado paper in the journal Matter2, discusses a range of novel polymer chemistries, among them covalent adaptable network (CAN) polymers. In the 2020 article, “Vitrimers, the reprocessable thermoset,” CW noted both the origin of many of these technologies in the lab of French (originally Polish) physicist Ludwik Leibler of ESPCI ParisTech and the centrality of research at the University of Colorado.

Since that article, novel CAN and vitrimer chemistries have been covered extensively in CW. While they are not always fully recoverable by the application of heat alone, recovery is often possible because interlocking molecular bonds can be chemically “unzipped.” Unlike epoxy, some semi-thermoplastic resins attain their full strength at room temperature without post-cure. In many cases, they are:

- Relatively ductile, making tough, impact-resistant composites possible without the addition of plasticizers;

- Formable with heat, making it possible to laminate flat panels and thermoform them afterward;

- Able to be joined using some form of plastic welding; and

- “Self-healing” at some temperatures.

Arkema’s Elium resin achieves at least some of the advantages of other thermoplastics while being less novel than vitrimers and reversible epoxies. Being relatively simple in its chemistry yet impressive in its properties, Elium is the first thermoplastic to gain significant use within the marine industry. That it’s mostly compatible with existing boatbuilding methods is an additional virtue.

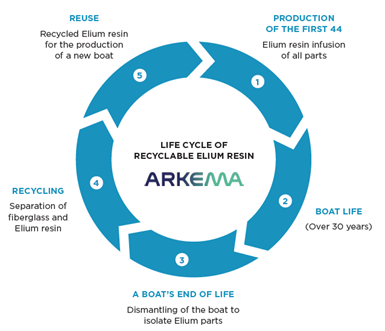

This graphic from Beneteau illustrates circularity as the concept applies to the company’s First 44e model made with Elium. Photo Credit: Beneteau Group

There are variations of Elium targeted to different markets. “Elium 188 or 191 series resins dedicated to marine and wind markets lead, after radical polymerization initiated by an organic peroxide, to a strictly linear polymer. This polymer can be softened to be compounded,” says Arkema global business director Guillaume Cledat. “Since Chebil et. al.1 was written, the formulation of Elium resins have been improved to be more robust and easier to use. A crosslinked version is available for markets where recycling is less crucial.”

Recycling Elium

With EOL Elium-based composites coming onto the market in the next few decades, action is being taken now to be ready to receive these materials for recycling or reuse. “We can count on consumables made from Elium-based composite materials to arrive in 2024-2025, with production waste from the manufacturing of boats and wind turbine blades,” says Arkema research engineer Jean-François Devaux. “These account for 5-10% of composite materials made, and this waste contains significant volumes of Elium resin, which we want to recover and reuse.” Hence the importance of demonstrating the feasibility of recycling processes to specialist operators, as well as their financial viability.

Both forms of Elium recycling involve crushing or chopping the composite first. Either process can be followed from there.

Recycling by thermal depolymerization (TDP). Heating the crushed/chopped composite above the resin’s Tm initiates thermolysis, allowing it to melt or “self-heal” to a flat sheet. The original fibers remain; separating them out is not part of this process. This will not result in the restoration of the composite’s original mechanical properties, but there are possible uses for materials recovered in this way.

“I think making pellets to use in 3D printing or an injection machine makes a lot of sense,” says Valloir. “It’s easy, you keep the fiber in it. And then, for example, if you grind a conventional ABS with 50% Elium scrap you save 50% of the cost and you enhance the property of ABS about 20%. That makes a lot of sense, technically speaking, financially speaking and as a waste stream strategy. The resulting product is recyclable as well, so it's a loop.” Arkema is working with the REVEL project to refine this process and study the resulting material’s properties and potential applications.

Recycling by solvolysis. Recycling Elium by solvolysis involves introducing specific chemicals and heating them along with the crushed composite material to about 400°F, turning the solid resin into a gaseous monomer. The resulting liberation and recapture of constituent chemicals enables new Elium resin to be created without the loss of physical properties. By this process, molds utilized in the construction of parts of the trimaran Arkema 4 were recycled to become part of a finely tuned racing machine, as described earlier. If this can be instituted on an industrial scale, circularity can be realized. Liberation of the reinforcement having been accomplished, the fibers (as shorter strands due to the initial crushing) can be recycled as well. Arkema’s partner programs working on this recycling technology include the ZEBRA program, which focuses on wind turbine blades, and MMAtwo, which is specific to acrylics.

(Left to right) Lalou Roucayrol of Neo Sailing Technologies (formerly Lalou Multi) and Arkema Racing, Jeroen Wats of Ultimate Boats (ExoTechnologies), Norbert Sedlacek Koch and Marion Koch of Innovation Yachts. The three men are noted offshore racers as well as boatbuilders, while Marion is a standout sailor in her own right with yacht and sports equipment design credentials. Photos Credits: Arkema, ExoTechnologies and Innovation Yachts

ExoTechnologies and Ultimate Boats

Like Lalou Roucayrol, Jeroen Wats is a successful offshore sailboat racer turned boatbuilder. Cognizant of the environmental impact of boats, and with a desire to innovate, Wats formed TYNC (The Young Naval Architects) in 2015, then set up a composites lab, 360 Quantillion Ltd. (Castletown, Isle of Man, U.K.). 360 Quantillion is a reference to the gallons of water in the sea. The lab is now the materials R&D hub of ExoTechnologies (Douglas, Isle of Man, U.K.).

“I love sailing, but I love the planet more.” explains Wats, now ExoTechnologies’ founder and chief innovation officer. “In Europe, 250,000 metric tons of glass fiber goes to landfills each year. Glass fibers are the new asbestos. Their annual production emits the same CO2 as seven countries.”

Moreover, recycling methods like solvolysis degrade fiberglass. Without a reinforcement that’s recoverable with its mechanical properties intact, would the recycling proposition be worthwhile? “You can separate a thermoplastic resin from the fibers, but the fiber is not reusable for the simple reason that it does not retain its strength,” notes Wats. In search of a durable, affordable material that could be reused at EOL, he tested thermoplastic resins with reinforcements other than E-glass, S-glass or carbon fiber. The quest resulted in ExoTechnologies’ Danu.

The reinforcement chosen for Danu, which Wats is keeping close to the vest, “handles the impact of chemicals very well.” In addition, “when we tested Danu and we saw the mechanical properties, we thought: This is much stronger than we ever dreamed! In some areas we were approaching carbon fiber properties.”

Answer in hand, Wats was introduced to Shane Mugan, the Irish owner of a Scottish boat company, Ultimate Boats. Together with an American partner, retired NOAA officer Michael J. Silah, they founded ExoTechnologies to promote sustainable composite solutions across multiple industries. Because wind blades are thick near the hub, the amount of material in a single wind blade is far greater than in most boats, so future production boat construction could utilize recovered material if the quality can be maintained. “The benefit, I personally think, of chemical recycling [solvolysis] is that if you’ve got a biaxial, you get a biaxial back,” explains Wats. He sees the goal not as recovering degraded short strand fibers, but as recovering significant lengths of woven or stitched fabric.

“The circular economy works when the virgin materials are more expensive than the recycled materials, and the quality is the same,” Wats continues. “With Danu, from a wind turbine blade you can make another wind turbine blade, from a wind turbine blade you can make a boat, or you can upcycle from a boat to make another wind turbine blade! And if not, let’s say recycled fibers go into a landfill; that has no ecological effect at all. Nature goes back to nature. There is no boric acid in it, and no toxics like you have with fiberglass.”

“Danu is a recipe named for the Celtic mother of Earth,” says Wats, describing the composite he developed. “It’s a technology around existing resins and fibers. The processes are where we’ve innovated. We were recently granted a U.K. patent and are now approaching sailboat builders.”

Ultimate Boats, an ExoTechnologies subsidiary, produces fast foam-collar RIB-style boats using Danu composites, often for government agencies in the U.K. Photo Credit: ExoTechnologies

The Ultimate Boats Co. (Clydebank, Scotland), an ExoTechnologies subsidiary, utilizes Danu throughout its product line, making it the first powerboat company to incorporate an infusible thermoplastic resin. “At Ultimate Boats, we made the first prototypes of the new hull in fiberglass, as we were developing Danu at that stage,” said Wats. “Then we switched — literally overnight — and have been building Danu boats since. It was that simple.”

“The strength in Danu is that the proposition is not expensive,” Wats adds. “People think it’s inferior, but it’s considerably stronger than GRP [glass fiber-reinforced polymer] and it’s fully recyclable, so it’s future proof technology. It’s the answer to upcoming legislation, eco-taxes and starting immediately, it’s the answer to tender applications if you’re doing deals with government.”

Armor is another market for Danu, made still more appealing by Kevlar’s recent supply issues. “We did a ballistic test and reached Level 3 according to the National Institute of Justice on a 5-pound, 12-millimeter-thick sample,” says Wats.

“We have something which is ballistic, recyclable, sustainable, circular and affordable,” he continues. “We’re not a commodity fiber, don’t get me wrong, but by the time you’re done you can build a boat with Danu that’s competitively priced.”

Innovation Yachts and Isomatex volcanic fiber

Innovation Yachts founder and managing director Norbert Sedlacek Koch had polar adventures in mind when conceiving Ant Arctic Lab, said to be an Open60AAL yacht. His wife and partner Marion Koch directed the design and engineering. Photo Credit: Innovation Yachts/Christophe Favreau

Because the process of “carbonizing” carbon fiber requires high heat, the material has a significant carbon footprint. CW has previously discussed an alternative, basalt fiber. As explained by author Karen Mason in “The still-promised potential of basalt fiber composites”:

“The fact that the raw material for basalt fiber is naturally occurring leads to one major technical hurdle: inconsistent raw material properties. That is, rock mined from different locations varies in the specific quantities of iron, magnesium, and other constituents.”

This problem is reportedly overcome by Isomatex S.A. (Gembloux, Belgium), the primary, but not exclusive, supplier of reinforcement fiber to Innovation Yachts (Les Sables d’Olonne/Vairé, France). Isomatex claims the ability to supply consistent product due to its sourcing and processing methods. It also claims the advantages of volcanic fiber closely parallel those of basalt fiber. Isomatex fiber brands include Filava and its successor, Tenron, an aerospace-grade mineral fiber. Note that Innovation Yachts refers to all of the reinforcement fibers it works with as “volcanic fiber” or “pure mineral fiber.”

By whatever name, these volcanic fibers are processed from the form of igneous rock that results from lava cooling quickly at the Earth’s surface. Said to be “extrusive,” this mineral is naturally aphanitic (fine-textured) relative to other igneous rocks. While volcanic fiber production involves melting basalt rock to 1,400-2,200℃, that requires less energy than the process of producing carbon fiber from polyacrylonitrile (PAN) or pitch.

All of the boatbuilders featured in this article emphasize toughness over stiffness in their approach to engineering. With that as the agenda, Filava and Tenron reinforcement fibers offer several advantages, including low density and high tensile strength with greater elongation to break than carbon fiber. Isomatex also claims recyclability.

Besides primary structures such as hulls and decks, volcanic fiber may have another boatbuilding application. Some race boats are now built of carbon fiber prepreg/epoxy heated in female molds. In many cases, those molds are made of carbon fiber to match the coefficient of thermal expansion (CTE) of the hull material. Unlike other reinforcements, the thermal expansion of basalt or volcanic fiber may be sufficiently like that of carbon fiber to make it a substitution candidate.

Innovation Yachts doesn’t generally employ prepreg, and often dispenses with a female mold in favor of building directly on a male jig. Like Greenboats (Bremen, Germany), a flax fiber boat construction company, Innovation Yachts utilizes bio-epoxy resin. Experimentation continues in the Innovation Yachts lab, but it’s a choice it stands by for the moment after having built boats using several resins, all supplied by resin development partner BTO Epoxy (Amstetten, Austria). Innovation Yachts continues to develop its own method of recycling its volcanic fiber/bio-epoxy combination, not only to provide a comprehensive approach to producing green boats, but to give the potential to incorporate recycled material into boat molds, bulkheads and interior panels.

Innovation Yacht’s display at Boot Düsseldorf in January featured the first boat, called the Volcat 16, to be built with Isomatix’s new “pure mineral fiber,” Tenron. Photo Credit: Innovation Yachts

“We have pursued our own composites development program since 2009, and probably have the most extensive basalt/volcanic fiber test database in the nautical industry having tested fiber from Asatec, Isomatex, Basaltex, DBF, Mafic and others,” says Norbert Sedlacek Koch, CEO of Innovation Yachts. “We developed several solutions with Isomatex starting in 2015. On our Open60AAL [boat], we used Filava for the most critical areas of the hull; for the rest, we used a unidirectional volcanic fiber that we produced from 2012 till 2015, FipoFix, along with ASA.TEC roving.” FipoFix was a UD volcanic fiber Innovation Yachts produced in-house from 2012 to 2015.

Innovation Yachts is not the only boatbuilder using basalt (or something similar). Windelo Catamaran (Canet en Roussillon, France) builds basalt fiber-reinforced boats, and Northern Light Composites uses both basalt and Arkena’s Elium resin to build its Ecoracers. Even so, Innovation Yachts has lived up to its name, earning its LBV35 catamaran the 2023 Ocean Tribute Award from Boot Düsseldorf.

Isomatix has just introduced a new mineral fiber, Tenron. Innovation Yachts presented the Volcat 16, in Düsseldorf in January 2024, representing the world’s first boat build from this mineral fiber. Use of Isomatex reinforcements in the wind energy sector is also being actively explored.

A new age in circularity

When reflecting back on the developments explored in this article, it seems that the goal of implementing a truly circular recycling strategy through the use of more sustainable fibers and resins in boatbuilding, or across several industries at a large scale, may be ambitious but achievable. Implementation will take coordinated efforts on several fronts involving end users, regulators, industry groups and government incentives — something we can already observe via the ongoing development in novel materials and processes. Those rising to the challenge are commended.

References

1Chebil, MS (April 2021). Oxidation and unzipping in ELIUM resin: Kinetic model for mass loss. Hal Open Science.

2Jin, Yinghua (December 2019). Malleable and Recyclable Thermosets: The Next Generation of Plastics. Matter.

About the Author

Stephen Ditmore

Stephen Ditmore worked in yacht design in the 1990s and then with plaster and cast stone for about 12 years where his work included the 3D modeling of a replica senate chamber elliptical dome ceiling made of glass fiber-reinforced gypsum for the Edward M. Kennedy Institute in Massachusetts. In 2014 he returned to school to study composites and quality assurance. Currently, he writes about polymers in medicine, transportation, renewable energy and the marine sector, and about medical clinical trials.

Related Content

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreCryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreManufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MoreRead Next

Al Seer Marine, Abu Dhabi Maritime unveil world’s largest 3D-printed boat

Holding the new Guinness World Record at 11.98 meters, the 3D-printed composite water taxi used a CEAD Flexbot to print two hulls in less than 12 days.

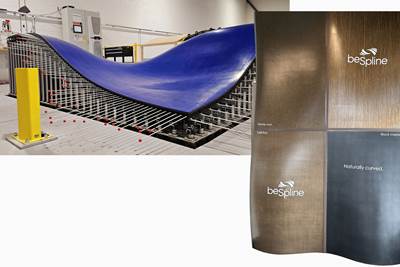

Read MorePlant tour: BeSpline/Addcomp, Sherbrooke, QC, Canada

Composites automation specialist increases access to next-gen technologies, including novel AFP systems and unique 3D parts using adaptive molds.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More