Norco selected as main composite supplier for UK Ministry of Defence contract

Norco is currently manufacturing two complete vessel structures to replace the interim Gibraltar Squadron Fast Patrol Crafts.

Photo Credit: Norco

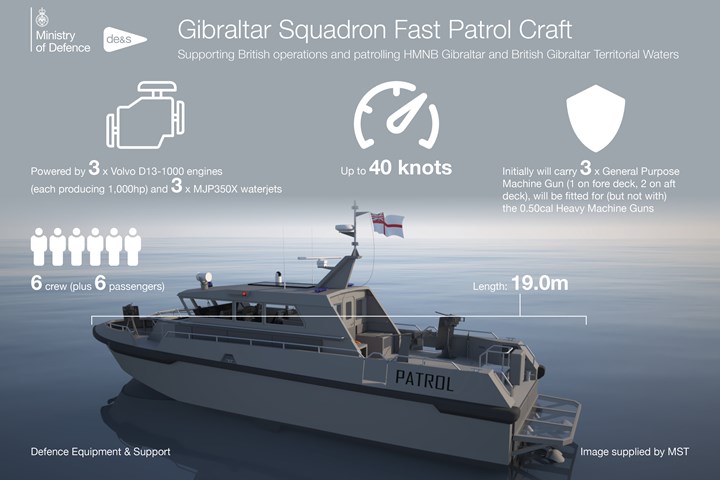

Norco (Dorset, Poole, U.K.), manufacturer of large glass fiber-reinforced polymer (GFRP) structures, reported in February 2020 that it has been successfully selected by Merseyside-based Marine Specialised Technology (MST; Liverpool, U.K.) as the company’s main composite supplier for a £9.9 million contract with the UK Ministry of Defence (MoD). The contract is to construct two new vessels to replace the interim Gibraltar Squadron Fast Patrol Crafts.

According to Norco, the construction of the two boats began in July, and will take approximately 18 months, with the first boat due to be delivered in the third quarter of 2021/2022; boat two is due for delivery in the first quarter of 2022/2023. Norco says it will manufacture the complete structure—hull, deck and wheelhouse—for the two vessels in line with MST’s production schedule.

“I am very happy to be working in partnership with MST again. Here at Norco, we pride ourselves on developing successful relationships with our customers to gain repeat business,” comments Mark Northey, managing director at Norco. “This project will add to our portfolio of defense contracts, which demonstrates our ability to deliver product that meets the stringent quality standards of the MoD.”

HMS Pursuer and Dasher, two Archer-class vessels are said to have recently taken over from Scimitar-Class vessels HMS Sabre and HMS Scimitar, while the two MST vessels are under-construction. The Scimitar Class vessels had been in service in Gibraltar for 17 years and were due an upgrade as part of the Royal Navy’s modernization program. These vessels maintain the security of British Gibraltar Territorial Waters.

“We are delighted to have Norco onboard with us for this prestigious defense project with the Royal Navy as they have proven in the past, on many occasions, that they can deliver quality composite structures on-time with their large capacity facilities,” adds Chris Hurley, project manager at MST.

Related Content

-

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

-

Milliken & Co. partners with MMI Textiles to offer Tegris thermoplastic

The commercial market partnership enables easier access to the Tegris thermoplastic composite fabric for defense customers in the quantities that they require.

-

US Air Force selects Integris Composites ballistic body armor

Cratus Wave armor is thin, lightweight and reduces heat stress, providing buoyant personal protection for the 582nd Helicopter Group.