CompositesWorld News

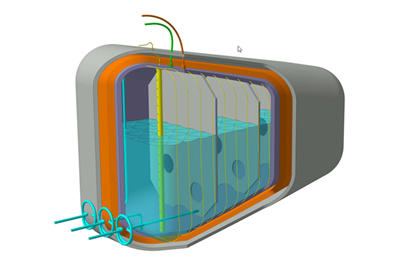

Collins Aerospace to lead COCOLIH2T project

Project for thermoplastic composite liquid hydrogen tanks aims for two demonstrators and TRL 4 by 2025.

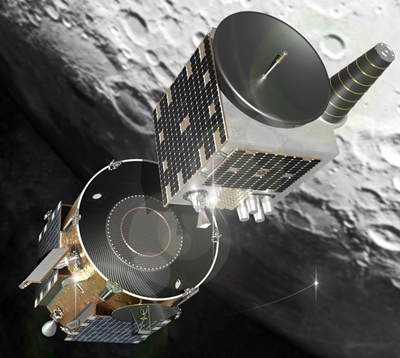

Read MoreNASA selects Firefly Aerospace for lunar surface payloads

Two agency payloads are targeted to launch in 2026 to a landing site on the far side of the moon to gain a better understanding of the early evolution of the universe.

Read MoreEirTrade Aviation undertakes disassembly activities for retiring Boeing 787s

The first two 10-year-old B787-8s to be retired from commercial service will be coordinated and managed in Prestwick, Ireland, with parts expected to be available in late Q1 2023.

Read MoreCollins Aerospace inaugurates Powered by Collins Initiative

Fostered technology development in collaboration with deep tech firms to advance technologies for UAS, composites recycling, batteries and space mobility.

Read MoreLotus Engineering innovates track bike for Paris Olympics 2024

Expertise from Lotus’ automotive projects in design, advanced engineering, lightweighting and product development are used to produce solutions in the wider transport and personal mobility sector.

Read MoreDITF develops water-spun lignin fibers as PAN precursor alternative

Lignin fibers produced via an aqueous solution and dry spinning process result in homogeneous, smooth-surfaced fibers that are more environmentally friendly and cost-saving.

Read MoreSikorsky hybrid-electric VTOL demonstrator to inform future missions

Long-range, autonomous HEX aircraft prototype featuring a composite airframe serves as evaluation of large VTOL aircraft design, novel propulsion systems and control architectures for military and commercial purposes.

Read MoreAIM3D, Naddcon implement digital process chain for 3D printing

The ExAM 255 multi-material 3D printer from AIM3D, integrated into Siemens’ NX design software, opens up new optimization possibilities for 3D-printed designs, demoed by a 3D-printed GFRP component.

Read MoreNASA names university teams for aeronautics research challenges

As part of the agency’s University Leadership Initiative, three multidisciplinary teams will address topics related to growth in AAM, while a fourth examines electricity generation for future airliners.

Read MoreAnmet launches chipboard panels made from recycled composites

Starting from university R&D collaborations, the Polish recycling company has patented a shredding and manufacturing process for wood-replacement chipboards for use by the construction industry.

Read More