AIM3D, Naddcon implement digital process chain for 3D printing

The ExAM 255 multi-material 3D printer from AIM3D, integrated into Siemens’ NX design software, opens up new optimization possibilities for 3D-printed designs, demoed by a 3D-printed GFRP component.

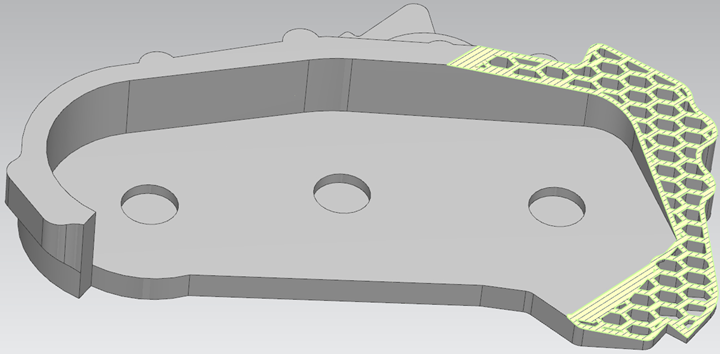

The optimized component made of glass fiber-reinforced polyamide is represented here within the NX program with a weight-optimized lattice structure. Photo Credit, all images: Naddcon

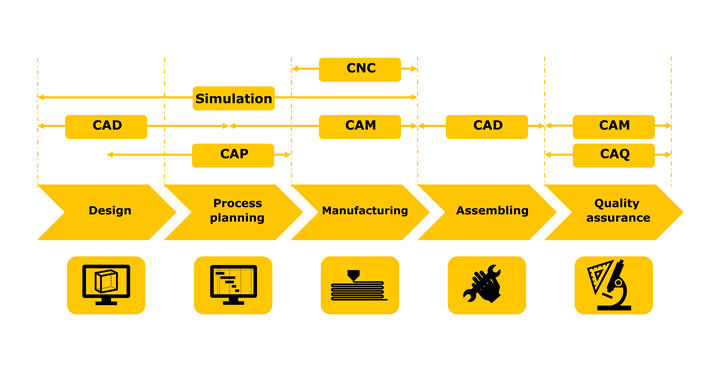

AIM3D GmbH (Rostock, Germany), in cooperation with Naddcon GmbH’s (Lichtenfels, Germany) research and development center, an additive manufacturing (AM) specialist, recently integrated an ExAM 255 3D printer from AIM3D with Siemens Digital Industries Software’s (Plano, Texas, U.S.) NX design software. The NX tool contains extensive CAD, CAM and CAE solutions, as already used for the conventional manufacturing of components in the machining industry. Naddcon integrated the software with AIM3D’s multi-material 3D printer in an effort to enable mapping the 3D printing process as a continuous digital process chain, from the component design to production and post-processing. For example, users can now make use of an alternative approach to operate 3D printers and to generate G-code.

The bridge between AIM3D’s machine firmware and Siemens NX’s CAD/CAM environment is reported to integrate the 3D printer into a CAM processing machine. With CAD, CAM and CAE approaches, NX offers the user a comprehensive tool for the design and iterative optimization of additive components. Based on a desired requirement profile, 3D components can be optimized in terms of bionics, free-form surfaces, selective densities (variable filling strategies) and weight reductions (for example, grid structures).

Composite 3D-printed demonstrator component. Original design (top) and NX-optimized design (bottom).

In addition, fiber reinforcement can be laid down in an optimized manner with respect to the force flow, which defines the stiffness or elasticity and the mechanical load capacity. A database system and simulation models are also available, meaning that the entire 3D printing process — from design to production — can be better controlled, components can be optimally designed and a high level of reproducibility can be achieved.

It is said that NX enables an exact machine simulation. More precisely, this means that traversing speeds, extruder performance and temperatures can be controlled with pinpoint accuracy depending on the component geometry, according to AIM3D and Naddcon.

Using the NX design software, Naddcon notes that generation of tool paths along curved surfaces is possible, ensuring that true 3D paths, which create planes independently, can be generated during the composite extrusion modeling (CEM) process inherent to AIM3D’s 3D printers. Moreover, using this technology in process development can eliminate the staircase effect typical of AM processes. The result is a true 3D contour of a solid body.

Sebastian Kallenberg, project engineer at Naddcon, demonstrated the capabilities behind this system integration via a standardized demonstrator component made of glass fiber-reinforced polyamide (PA6 GF30), the design of which was to be optimized using NX.

First, Kallenberg built a kinematic model of the 3D printer by integrating the CAD model of the ExAM 255 into NX, as well as defining the kinematic axes and determining the machine zero point. The kinematic model enables a machine simulation of the tool paths before the actual production process takes place. The next step was the generation of the tool path for the extruder of the AM system. This involves generating trajectories based on machining operations and the component geometry. Third was the machine simulation of the ExAM 255 — that is, the simulation of the tool path with the associated axis movements of the machine model. The application of the material, as well as potential machine collisions, can also be simulated. The main aspect here is the programming of a post-processor to translate the NX tool paths into a numerical G-code that the 3D printer can interpret.

A G-code consists of path conditions (G-word) and additional functions (M-word), each of which are assigned either a movement or an action. The combination of these commands allows the 3D printer to understand the pattern it must follow to produce the part. In 3D printing, a G-code is usually generated automatically by the slicer software when the design is converted to an STL file. Post-processor programming enable machine-specific adjustments for an improved process control. When using NX, however, an STL format is no longer necessary, as the process makes use of solids that are either directly generated within NX or can be imported from a different CAD system.

To develop the sample component, the tool path was generated, and tests were carried out on the ExAM 255 machine to identify the optimal process parameters, but also possible errors in the post-processor. For an optimized design, NX enables the user to vary densities, integrate lattice structures to reduce weight, control shrinkage, apply stiffeners and move “drill holes.”

“Our digital NX approach is intended to better exploit the CEM machine technology from a design and production preparation point of view,” Kallenberg says. “There is considerable potential here for free-form surfaces, that is, real 3D contours, but also bionic design strategies.”

Learn more about the potential of composite extrusion modeling (CEM), or have AIM3D’s 3D printers target precise, cost-effective polymer processing

Related Content

Hybrid process marries continuous, discontinuous composites design

9T Labs and Purdue applied Additive Fusion Technology to engineer a performance- and cost-competitive aircraft bin pin bracket made from compression-molded continuous and discontinuous CFRTP.

Read MoreLarge-format 3D printing enables toolless, rapid production for AUVs

Dive Technologies started by 3D printing prototypes of its composite autonomous underwater vehicles, but AM became the solution for customizable, toolless production.

Read MoreThe next evolution in AFP

Automated fiber placement develops into more compact, flexible, modular and digitized systems with multi-material and process capabilities.

Read MoreReinforcing hollow, 3D printed parts with continuous fiber composites

Spanish startup Reinforce3D’s continuous fiber injection process (CFIP) involves injection of fibers and liquid resin into hollow parts made from any material. Potential applications include sporting goods, aerospace and automotive components, and more.

Read MoreRead Next

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More