AFPT participates in LeiWaCo project for economic production of thermoplastic composite hydrogen tanks

Laser winding/welding will help 3-year project develop cross-industry container-based transport/supply unit for cryogenic liquid hydrogen, aiming for TRL 5 via demonstrator manufacture and testing.

AFPT (Dörth, Germany), supplier of equipment and technology for automated fiber placement (AFP), laser-assisted tape winding (LATW) and welding, is participating in the 3-year LeiWaCo project that is funded by the German government and led by the Composite Technology Center (CTC, Stade, Germany), an Airbus company.

The LeiWaCo project began in November 2022 and is targeting developments to aid economic series production of thermoplastic composite pressure vessels for use as liquid hydrogen (LH2) tanks in aviation and other transportation applications. Partners in the Germany-based consortium include:

- AFPT (Dörth)

- ARGO-ANLEG (Wesel)

- CompriseTec (Hamburg)

- CTC Composite Technology Center (Stade)

- DLR – Insitut SY (Stade)

- DLR – Institut RY (Bremen)

- eCap Marine (Hamburg)

- Faserinstitut Bremen e.V. (FIBRE, Bremen)

- Fachhochschule Nordwestschweiz (FHNW, Münchenstein, Switzerland)

- IDVA (Freiburg im Breisgau)

- Schunk (Lauffen am Neckar)

- Suprem (Yverdon-les-Bains, Switzerland)

- Teijin Carbon Europe (Wuppertal).

LeiWaCo project description

In a project description by enArgus.de, LeiWaCo will develop a cost-effective and high-strength lightweight tank made of fiber-reinforced composite materials for storing LH2 with the aim of using it in a new, cross-industry logistics solution in the form of a container-based transport and supply unit. The project’s cross-industry consortium is also considering the adaptation of the developed technologies for tanks in aviation, marine shipping, road and rail transport.

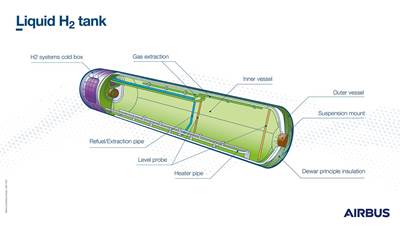

One of the main challenges is that LH2 must be stored at cryogenic temperatures to prevent evaporation into gas at its boiling point of -253°C. Part of this challenge is providing sufficient resistance to permeation of the very small H2 molecules, a key performance requirement that may be impaired by thermally induced microcracks in the material due to the low temperatures required. The LeiWaCo project aims to prevent this via a new approach: The use of thermoplastic materials in combination with the application of thin film technology. To achieve this, the project will develop new design and calculation methods, new semi-finished products and material tests and corresponding manufacturing technologies and test methods.

The LeiWaCo project will include the entire value chain and validate its developments using demonstrators, which will be tested in a setup representing the operational environment to prove the essential technical elements. This corresponds to a technology readiness level of TRL 5 and will include appropriate production technologies and test methods for the thermoplastic composite LH2 pressure vessel.

AFPT contributions

AFPT has participated in numerous industry projects, including TopTape for LATW with integrated quality inspection, the Clean Sky Sonaca Wing flap for large passenger aircraft, Maremo for reusing/recycling towpregs, Comet for additive layer manufacturing (ALM), COMMUNION for 3D joining of metals to thermoplastic composites and more.

“The laser welding technology developed by AFPT provides precise processing of thermoplastic composites that ensures high quality and efficiency in production,” says Patrick Kölzer, one of the founders and managing directors of AFPT. “By combining our technology with other leading technologies in the lightweight industry, the LeiWaCo project will enable economical series production of hydrogen tanks, which is of great importance for the energy transition and the achievement of sustainability goals. We are proud to contribute to this important project and continue to develop innovative solutions that optimize the production of hydrogen tanks and other lightweight components.”

Part of this contribution is AFPT’s laser-supported processing of thermoplastic composites which enables the coupling of thermal cameras and data analysis to provide inline process control for production of high-quality thermoplastic components that meet rigorous industry standards. This ensures that the reliability and safety demanded for pressure vessels in aerospace and other transportation applications are met. In addition to these industries, AFPT claims its technology makes it possible to also efficiently produce high volumes of thermoplastic composite components for industrial applications as well as sporting goods and consumer products.

Related Content

Jeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreWelding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreRead Next

CFRTP upper stage propellant tank

PROCOMP uses in-situ consolidation AFP and ultrasonic welding to demonstrate lightweight, novel tank design.

Read MoreZeroAvia and Absolut Hydrogen partner to develop liquid hydrogen refueling infrastructure for aircraft operations

Partnership supports development of LH2-powered aircraft with up to 80 seats by 2027 and robust airport infrastructure.

Read MoreWill the Airbus-CFM H2 flight demonstrator use metal or composite tanks?

The Airbus A380 testbed will fly in 2026 with four 100-kilogram liquid hydrogen tanks — metal and composites are being developed via Airbus ZEROe Development Centres — with multiple other programs to develop composite H2 tanks for civil aviation that were begun in 2021.

Read More

.jpg;maxWidth=300;quality=90)