AFPT GmbH

Trinkbornstrasse 10

Doerth, 56281 DE

49 6747 9501 850

info@afpt.de

afpt.de

About AFPT GmbH

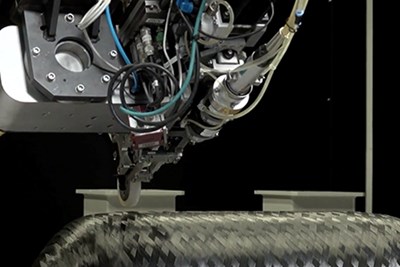

Developed, manufactures and markets laser-assisted automated tape placement technology for thermoplastic composites.

IS THIS YOUR COMPANY?

As Seen On CompositesWorld

AFPT GmbH Supplies the Following Products

- Automated fiber placement systems

- Automated tape laying systems

- Filament winding machines and controls

Editorial, News, and Products

-

Composites end markets: Pressure vessels (2024)

The market for pressure vessels used to store zero-emission fuels is rapidly growing, with ongoing developments and commercialization of Type 3, 4 and 5 tanks.

-

Digital Composites Factory joint venture to grow thermoplastics manufacturing

Together, AFPT, Alformet and New Frontier Technologies are fostering a productive environment for development of well-designed thermoplastic composites via automation, innovative design and advanced 3D expertise.

-

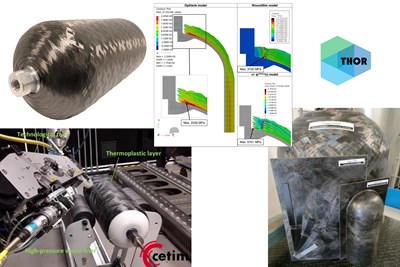

Update: THOR project for industrialized, recyclable thermoplastic composite tanks for hydrogen storage

A look into the tape/liner materials, LATW/recycling processes, design software and new equipment toward commercialization of Type 4.5 tanks.

-

Composites end markets: Industrial (2024)

The use of composites in industrial applications is increasing, driven by the need for higher performance and longer life, whether its parts for industrial machinery, EOAT components, corrosion-resistant equipment and more.

-

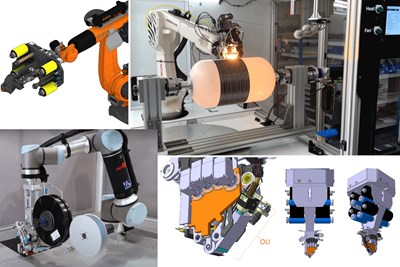

The next evolution in AFP

Automated fiber placement develops into more compact, flexible, modular and digitized systems with multi-material and process capabilities.

-

AFPT combines tape winding, placement into one tool

Typically separate processes, the company’s new vessel winding head (VWH), merged with a multiple tape laying head (MTLH) progresses composite pressure vessel development.

-

AFPT, Alformet advance bending of thermoplastic composite tubes

Specialists in AFP and LATW discuss process and lessons learned for new applications in CFRTP parts.

-

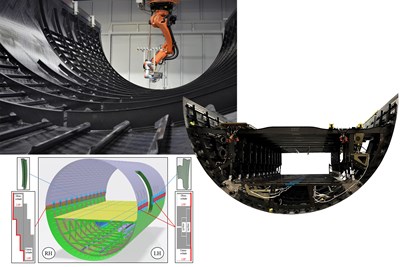

Manufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

-

THOR project develops mass-producible CFRTP hydrogen tanks

The three-year project, concluded in 2022 and aided by partners spanning the entire hydrogen storage supply chain, tested and produced 15 thermoplastic tanks, with the goal of achieving broader market introduction.

-

AFPT participates in LeiWaCo project for economic production of thermoplastic composite hydrogen tanks

Laser winding/welding will help 3-year project develop cross-industry container-based transport/supply unit for cryogenic liquid hydrogen, aiming for TRL 5 via demonstrator manufacture and testing.

-

AFPT GmbH acquires Alformet BV, celebrates 20 years

Combined know-how and company visions, and the founding of Alformet GmbH, aim to enhance the availability and delivery of high-quality fiber-reinforced thermoplastic composite solutions to customers.

-

JEC Composites presents 2023 Innovation Award finalists

This year’s 30 Innovation Award finalists representing 11 categories portray excellence in composites innovation and fruitful collaboration.

-

DLR completes MFFD upper shell skin layup

Eight-meter-long CFRTP fuselage skin was achieved via laser-heated in-situ consolidation, with stringers, frames and cleats to be welded.

-

CFRTP upper stage propellant tank

PROCOMP uses in-situ consolidation AFP and ultrasonic welding to demonstrate lightweight, novel tank design.

-

AFPT GmbH expects to acquire composite tube manufacturer

Netherlands-based Alformet BV will enable AFPT to expand the use of tubular, fiber-reinforced thermoplastic structures across a wide range of end markets.

-

DLR Institute of Structures and Design increases maturity of thermoplastic composite fuselage structures

Project with Airbus demonstrates OOA co-consolidated stringer-stiffened skin with resistance welded frame and cleats.

-

Future composite manufacturing - AFP and Additive Manufacturing

TU Munich symposium explores how these technologies are merging and reviews R&D that is creating a path forward.

-

3D printing CFRP molds for RTM flaperon, exoskeletons and more

The Chair of Carbon Composites at TU Munich is advancing composite additive manufacturing via large-scale extrusion, continuous fiber printing, integrating heating into tools and more.

-

Rocket module manufactured with in-situ consolidation survives first flight test

A carbon fiber-reinforced thermoplastic (CFRP) module developed at the Technical University of Munich survived its first launch — and a “hard landing” — in March.

-

CFRP module saves weight on rocket design

Taking advantage of carbon fiber/PEEK mechanical and thermal performance, the Technical University of Munich replaces an aluminum rocket module with a 40+% lighter composite alternative.

-

INOMETA invests in new laser-assisted tape winding technology

Using the new automated manufacturing process, the company aims to expand its current thermoplastics product range with an eye toward mass production.

-

Thermoplastic composite demonstrators — EU roadmap for future airframes

There is a TPC development roadmap in Europe, supported by Airbus and a variety of aerospace consortia, and involving almost every major aerostructures supplier in Europe.

-

Thermoplastic composites technology: A view from Europe

For this Dutch consortium, bringing the manufacturability of thermoplastic materials to maturity is the goal in concert with OEMs, materials and equipment supplier members.

-

JEC COMPOSITES 2009 Product Showcase

Despite the doleful state of the global economy, the turnout in Paris — exhibitors and visitors — proved surprisingly strong.

-

JEC Composites 2009 showcase

Despite the doleful state of the global economy, the turnout in Paris — exhibitors and visitors — proved surprisingly strong.