Airbus and partners to establish aircraft lifecycle center in China

Facility will offer sustainable solutions to manage the entire lifecycle of aircraft, including maintenance, conversions, dismantling and recycling.

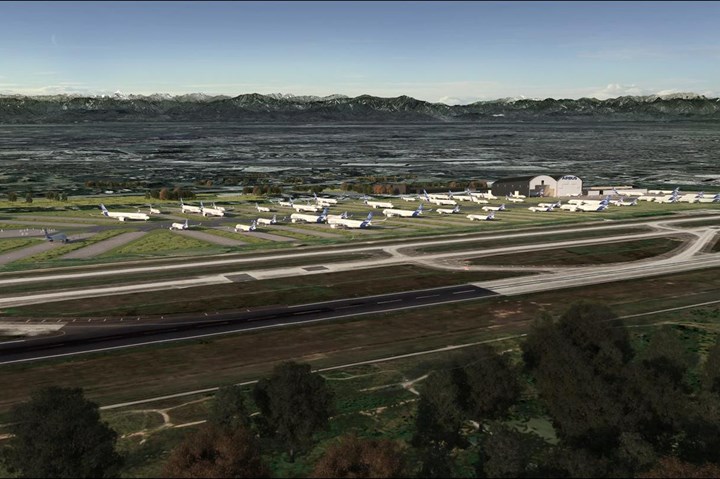

Airbus aircraft lifecycle center in Chengdu, China. Photo Credit: Airbus

On Jan. 18 Airbus (Toulouse, France) announced it has signed a Memorandum Of Understanding (MOU) with the city of Chengdu, China, and Tarmac Aerosave — a maintenance, repair and overhaul (MRO) company dedicated to aircraft storage, maintenance and recycling — for the development of the first sustainable aircraft “lifecycle” service center in China. This agreement will cover a range of activities from aircraft parking and storage, to maintenance, upgrades, conversions, dismantling and recycling services for various aircraft types.

“This is another concrete contribution to the aviation industry’s quest for sustainability, supporting the principle of a circular economy in line with Airbus’ purpose to pioneer sustainable aerospace. This center will support the expansion of Airbus’ aviation services while enabling the implementation of China’s “Green Industry” strategy,” says Klaus Roewe, SVP Airbus Customer Services. “Aircraft phase-out in China is forecast to grow exponentially over the next 20 years. Airbus is committed to investing in the region and this one-stop-shop — a first in China and outside of Europe — will see Airbus well positioned on the Chinese aircraft ‘second life’ services market.”

A formal agreement to establish and frame this industrial cooperation is planned to be signed between the partners in mid-2022, with an entry into service of the new center slated for the end of 2023, subject to relevant regulatory approvals.

Tarmac Aerosave says it will bring its 15 years of proven expertise in eco-efficient aircraft dismantling to the project. Located in the same center, Airbus subsidiary Satair (Copenhagen, Denmark) will acquire aging aircraft, trade and distribute the resulting used parts to complete the full scope of lifecycle services. The facility will cover a surface area of 690,000 square meters and a storage capacity of 125 aircraft.

Airbus continues to deploy its sustainability roadmap for the aviation industry, enabling the increased re-use of aircraft and the recycling of materials and equipment.

Related Content

-

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

-

Manufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

-

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.