Airtech 3D-printed resin delivers advanced manufacturing capabilities to U.K. defense sector

Carbon fiber-reinforced, PEI-based Dahltram I-350CF resin system enables production of high-temperature mold tooling for next-gen combat air demonstrator.

Share

Read Next

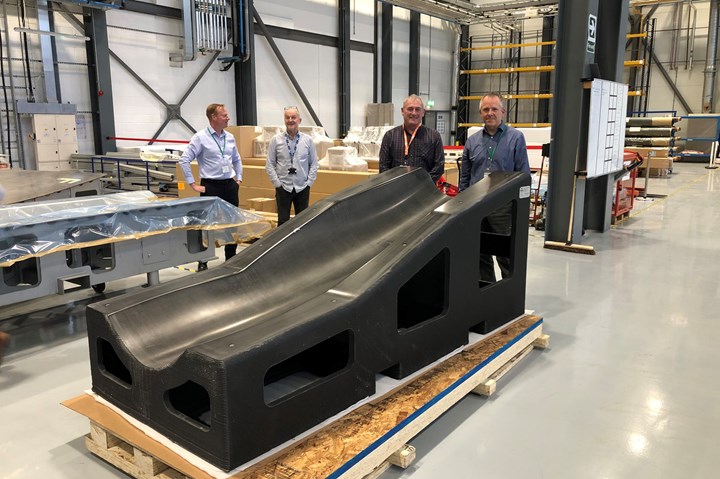

3D-printed tool. Photo Credit: BAE Systems.

BAE Systems (Farnborough, U.K.) reported on May 20 that it is using large-scale 3D printing to produce high-temperature mold tooling using Airtech’s (Huntington Beach, Calif., U.S.) Dahltram I-350CF resin for the production of a future combat air demonstrator.

Dahltram I-350CF system is a high-temperature capable, carbon fiber-reinforced, PEI-based 3D print resin, which has been adopted by the aerospace industry. BAE Systems says it has been working on the development of the manufacturing process with Airtech Advanced Materials Group and Ingersoll Machine Tools, Inc. (Rockford, Ill., U.S.) which printed the mold tool on its MasterPrint large-format 3D printing platform.

The Dahltram range of resins are suitable for multiple print platforms, providing production flexibility with end-use material approvals. Airtech has been able to demonstrate technology readiness and manufacturing readiness with its Dahltram range of resins and its own in-house tooling 3D print service. Continuous thermal cycle testing, pressure leak testing, laser surface scanning and contact material testing have reportedly generated data supporting more than 250 autoclave cycles, without degradation of the Dahltram manufactured tooling. Airtech Advanced Materials Group also has Dahltram Additive Manufacturing Resins and Print-Tech large-scale 3D-printed tool manufacturing capability in the U.S. and Europe.

Related Content

-

TU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

-

Bio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.

-

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.