AMRC fiber handling expertise aids CMC coating technology

The CICSiC project successfully developed equipment and processing know-how associated with the uniform, continuous coating of SiC-based CMC, to bring down cost, and improve performance and reliability for new designs, applications.

Share

Read Next

AMRC technical fellow, Steffan Lea processing silicon carbide (SiC) fiber on a 3D weaving loom. Photo Credit, all images: AMRC

Lower emissions and increased aircraft performance are benefits of a novel prototype machine developed by an industrial consortium that includes the University of Sheffield Advanced Manufacturing Research Centre (AMRC, Catcliffe, U.K.), designed to improve the coating technology for ceramic matrix composites (CMC).

The AMRC has collaborated with Archer Technicoat Ltd. (ATL, Wycombe, U.K.), TISICS Metal Composites (Farnborough, U.K.) and Cygnet Texkimp (Northwich, U.K.) to deliver a project on “Continuous Interface Coating for Silicon Carbide (SiC) composites,” or CICSiC for short. The project focused on the manufacture routes for SiC-based CMCs — a material of particular interest for high-temperature applications of up to 2,000°C in sectors such as aerospace, space and nuclear. The delivery of the project builds on the AMRC’s reputation as one of the leading centers nationally for research in the manufacture of these materials.

The interface between the fiber reinforcement and the matrix is a critical component of CMC. CICSiC aimed to develop equipment and processing know-how for uniform, continuous coating of interfaces on SiC fibers, such that the mechanical properties of SiC-based CMC can be more closely specified to enhance their aerospace applications. This enables the development of more efficient engines, offering significantly lower weight, lower cooling requirements and lower aircraft emissions — resulting in a reduced impact on the environment.

“SiC-based CMC are a promising material for many extreme environment applications including aeroengines,” says Ryan Skillett, technical manager at ATL. “The CICSiC project kick-started the development of a new method for manufacturing these high-value materials, aiming to simultaneously bring down costs while improving performance and reliability.”

The project sought to develop a new reel-to-reel coating technology to replace the current batch coating method to apply interphase coatings to CMC. In the batch coating method, a preform is made from uncoated fiber which is treated in one step, making it difficult to ensure an even coverage of all areas of the preform with equal precision. The new method uses a reel-to-reel process to apply the interphase coating instead. Material is wound from its original spool onto a new spool with the interphase being applied in between. This ensures a uniform coating. As the material is still on a spool, it can easily be used in fiber processing technologies. This enables shapes with increased complexity to be formed with a uniform interphase coating.

Skillett says the results of the project have drawn international interest from specialists. “The project worked towards the creation of a continuous fiber coating system to work in harmony with the existing batch-based technology, and in doing so, look to take on some of the major barriers to market for the product. The results of this project have drawn international interest from specialists in the material, leading us to believe it has a very bright future.”

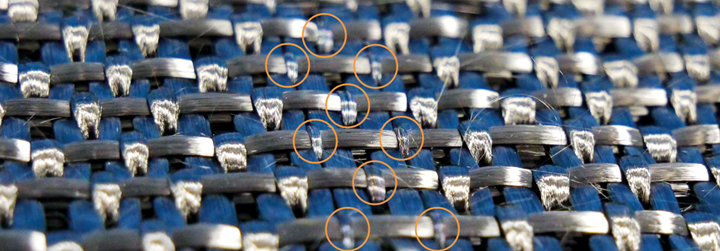

Nicalon fibers (circled) used as binder yarns in an 8-layer orthogonal 3D woven textile made up of 12K PAN fibers.

The AMRC’s role in the project focused on the industrial scale processing of SiC fibers to produce preforms with increased complexity. The ability to process the fiber is key to realizing the potential of this material, AMRC notes. Using SiC fibers in processing technologies such as weaving and tailored fibre placement (TFP) is important for building confidence in the handling of these materials so that they can be adopted into industry, and understanding the current processing limits.

The work on handling fibers was performed on as-purchased SiC and on SiC provided by ATL that had undergone the coating procedure in order to understand the difference in processing requirements, limitations and the quality of the output.

“Silicon carbide composites [SiC-SiC] are of interest to many industry sectors looking at high-temperature applications,” says Steffan Lea, a technical fellow in the AMRC’s composites team. “The ability to produce more complex preforms from continuous SiC fiber will enable new designs and applications for this high-performance CMC material.”

Lea adds that “during the CICSiC project, the AMRC has gained familiarity and knowledge on how to process SiC fiber on industrial-scale machines. Our knowledge on how to process SiC fibers on weaving looms to produce 3D woven preforms enables the production of unitized preforms with added complexity. Using the Nicalon on TFP allows us to make efficient use of the material, only placing it where it is required and controlling the path of the fiber to make best use of its properties.”

CICSiC was funded by the National Aerospace Technology Exploitation Programme (NATEP), a £15 million program to develop 60 aerospace technologies in the U.K. aerospace supply chain. Funded by the Aerospace Technology Institute (ATI) and managed by ADS, it is aimed at small- to medium-sized enterprises (SMEs) to develop innovative technologies to enhance their capabilities and increase their ability to win new business.

Related Content

New CMC turbine vanes successfully tested in wind tunnel

SiC/SiC ceramic matrix composite (CMC) inlet guide vanes for a high-pressure turbine are aimed for a geared turbofan and show promise for more efficient aeroengines with less weight and need for cooling.

Read MoreORNL, Sierra Space create novel C/SiC TPS for reusable space vehicles

CMC tiles will be used on the Sierra Space DC100 Dream Chaser spaceplane carrying critical supplies and science experiments to and from NASA’s ISS.

Read MoreSRI advances CMC for solar, renewable energy and industry

U.S. research institute advances “infiltration-free” process for improved performance, durability and affordability of materials able to withstand highly corrosive environments at temperatures beyond 700°C.

Read MoreDITF Denkendorf advances sustainable carbon fibers, oxide fibers for CMC and more

The German Institutes of Textile and Fiber Research are targeting more sustainable carbon fiber via low-pressure stabilization and bio-based precursors, and working with Saint-Gobain to commercialize oxide ceramic fibers for CMC.

Read MoreRead Next

Lockheed Martin expands development, production of ultra-high temp CMCs with facility expansion

Targeting current and future needs in hypersonic and aeronautics applications, Lockheed Martin Skunk Works’ Allcomp team is increasing and digitizing its capabilities in ceramic matrix composite (CMC) materials and parts fabrication.

Read MoreTechnology Innovation Institute AMRC explores novel metamaterial shapes for better shock, vibration shielding

Exploration of precisely engineered lattice structures including triple periodic minimal surfaces (TPMS) serve to develop more predictable, lightweight, high-performance sandwich cores.

Read MoreCollaboration between NCC, UKAEA to develop fusion-grade SiC/SiC composites

High-volume composites development for future fusion power reactors under HASTE-F program accelerates U.K.’s net-zero energy generation, drives transformation in industries that use high-temperature CMCs.

Read More