Anisoprint launches basalt fiber for continuous-fiber 3D printing

The material is said to be 15 times stronger than plastic, five times lighter than steel and 1.5 times stronger and lighter than aluminum.

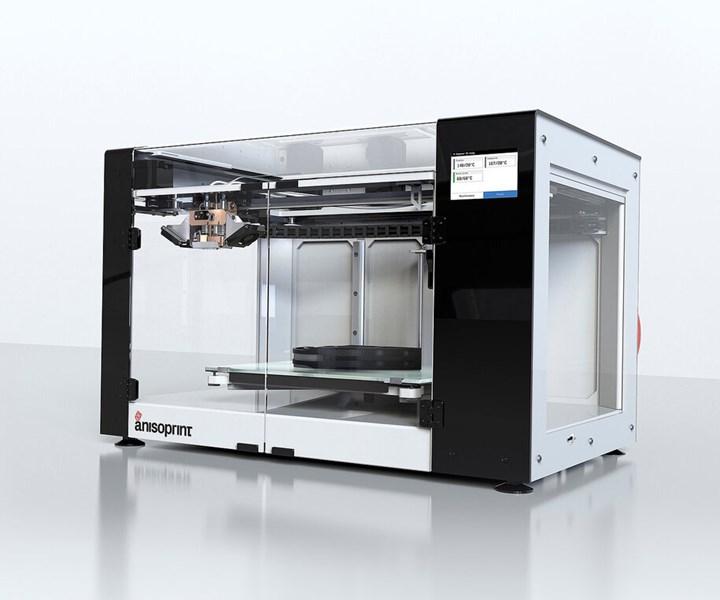

Anisoprint’s basalt fiber composite is available for use with its Composer continuous-fiber 3D printer. Source | Anisoprint

Anisoprint (Esch-sur-Alzette, Luxembourg), a manufacturer of continuous carbon fiber 3D printers and materials, recently launched a basalt fiber composite for use with its 3D printing technology.

According to the company, the material, when applied to its 3D printing technology, is 15 times stronger than plastic, five times lighter than steel, and 1.5 times stronger and lighter than aluminum. It also is said to significantly decreases manufacturing costs.

Since basalt fiber also features radio transparency, Anisoprint says that parts made of its basalt fiber composite do not significantly alter the amplitude and phase of radio-frequency electromagnetic waves transmitted through them, making it an ideal option for non-conductive elements and isolators.

Anisoprint’s technology involves continuous composite fiber coextrusion with thermoplastic polymers and enables variations in fiber direction, volume ratio and material density.

Related Content

-

Cryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

-

Dawn Aerospace reusable rocket-powered aircraft flies twice in one day

Eighth and ninth flights of composites-intensive Mk-II Aurora reach an altitude of 63,000 feet, demonstrates same-day reusability capability for rocket-powered systems.

-

Paris Air Show 2023 highlights

The Paris Air Show, one of the largest aerospace trade shows in the world, returned for the first time since 2019 and proved that the global aviation industry industry is very much alive and kicking.

.jpg;width=70;height=70;mode=crop)