AZL Aachen announces new project on composite rotor sleeves

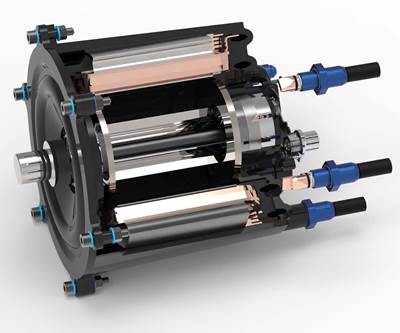

Joint Partner Project aims to address the growing demand for more efficient, powerful and compact electric motors in mobility and industrial applications.

AZL Aachen GmbH (Aachen, Germany) announces a “Joint Partner Project” focusing on composite fiber reinforcement sleeves for electric motors. The 9-month project, titled “Rotor Sleeves for Electric Motors: Potentials for Composite Materials and Technologies,” will investigate current and future applications for electric motors, their requirements for armoring sleeves and provide technological insights. Companies interested in the project can join the consortium consisting of Kümpers GmbH, Rassini and Schunk Kohlenstofftechnik GmbH, among others, until the kick-off on Sept. 12, 2024.

Compared to metals, composite rotor sleeves with their high stiffness, low density, almost zero thermal expansion and favorable electromagnetic properties are particularly suitable to contribute to all the highly focused development goals.

The application, manufacturing and material technologies for composite rotor sleeves have been proven to be mature, so far mostly in niche high-power applications. Due to the increasing demand for efficient electric drives, the demand for rotor sleeves and the corresponding production volumes is growing rapidly. Composite-based rotor sleeves are expected to expand into mass applications for electric vehicles, power tools, machine tools, electric aircraft and other industrial applications.

"As a manufacturer of composite materials, we develop and produce customised towpregs and prepreg unidirectional tapes for a wide range of applications,” says Dietmar Hoffstedde, expert for composite towpregs and prepregs, Kümpers GmbH. “With the increasing demand for efficient electric motors, the importance of rotor sleeves in mass production has increased, which achieve a very high level of performance, particularly when processed with towpregs. The AZL Joint Partner Project is a promising opportunity to gain impulses for the further development of our material and market expertise. With the AZL approach of bringing together supply chain players in a Joint Partner Project, we look forward to expanding our network and discovering new solutions.”

AZL will bring together experts from across the value chain to investigate current and future applications, analyse requirements and assess the impact on design, material selection and production concepts.

Throughout the project, participants will gain a comprehensive understanding of rotor sleeve technology and its applications in electric motors. The team will conduct extensive screening of current and future applications, explore different materials and processes for rotor sleeve manufacturing and analyse design options.

The requirements and expertise of electric motor designers and manufacturers will be combined with the manufacturing and materials expertise of AZL’s advanced materials network. In addition, the project will evaluate the cost and carbon footprint of alternative designs and production concepts, ensuring a holistic approach to support the business and technology development of the project participants along the entire value chain of electric motors with composite rotor sleeves.

Related Content

McLaren celebrates 10 years of the McLaren P1 hybrid hypercar

Lightweight carbon fiber construction, Formula 1-inspired aerodynamics and high-performance hybrid powertrain technologies hallmark this hybrid vehicle, serve as a springboard for new race cars.

Read MoreCryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreTPI manufactures all-composite Kenworth SuperTruck 2 cab

Class 8 diesel truck, now with a 20% lighter cab, achieves 136% freight efficiency improvement.

Read MoreASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

Read MoreRead Next

Reducing heat in EV motors via fiber-reinforced thermoset housing and stator

German researchers demonstrate fiber-reinforced phenolic motor housing and alumina-filled epoxy overmolded stator with integrated cooling circuits for reduced weight, increased power density and efficiency.

Read MoreProtecting EV motors more efficiently

Motors for electric vehicles are expected to benefit from Trelleborg’s thermoplastic composite rotor sleeve design, which advances materials and processes to produce a lightweight, energy-efficient component.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More