As electric vehicle (EV) technology advances to improve vehicle performance and range, battery technology may be grabbing many of the headlines, but equally important are the electric motors that convert battery energy to vehicle propulsion. For many years, one type of EV motor called a permanent magnet motor (PMM) has incorporated a carbon fiber-reinforced thermoset sleeve that wraps around the PMM’s rotor. The sleeve keeps the rotor assembly from flying apart at high rotational speeds. In a recent advancement, Trelleborg Sealing Solutions (Albany, N.Y., U.S.) has leveraged some advantages of thermoplastic resins to develop an improved design for the sleeve. Increased motor efficiency may soon propel the Trelleborg design into production EV motors.

In the EV market, PMMs have recently been selected for several production vehicles over the more common induction motor. These include the Tesla Model 3 and the Chevrolet Bolt and Volt. Induction motors feature a relatively low cost and high reliability, but PMMs offer higher power density and lighter weight. The price of PMMs is a decided disadvantage, due to the high cost of permanent magnets — most commonly made of rare earth metals. Therefore, every advancement that increases the efficiency of these motors is critical to building a business case for them. This is why Trelleborg’s carbon fiber-reinforced thermoplastic (CFRTP) sleeve for PMMs is under serious consideration for the EV market.

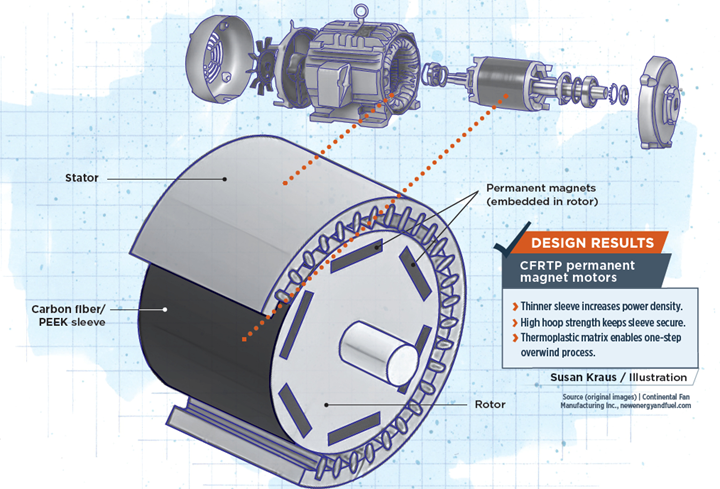

Electric vehicle motor options. Permanent magnet motors produce their own electromagnetic field via embedded magnets, different from induction motors, which are magnetized by electric power from the battery. Photo Credit: newenergyandfuel.com

“We have built a couple sleeves for evaluation in this market, though we can’t elaborate at this time,” Trelleborg product manager, Reid Hislop reports. But commercial application to the EV market seems likely on the near horizon. Trelleborg’s proven composite design and manufacturing technology have already been incorporated into PMMs for other commercial applications, such as industrial pumps and drives for machine tools, down-hole oil and gas pumps, and HVAC equipment.

Powering EVs

EV motors operate through electromagnetic forces. A rotating magnetic field is produced in the stationary component, the stator, by applying an alternating electric current. The stator surrounds the rotating component — the rotor — which is also magnetized. The resulting magnetic attraction and repulsion between the two components forces the rotor to rotate and power the drivetrain.

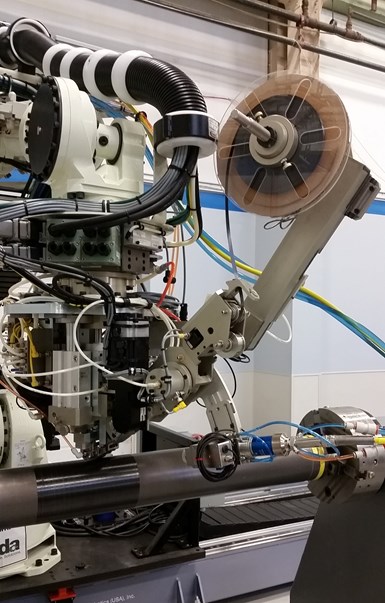

CFRTP sleeve. With its automated fiber placement (AFP) with in-situ consolidation, Trelleborg overwinds carbon fiber/thermoplastic composites directly onto metal structures. Pretensioning the composite material keeps it in place even for applications with high rotational speeds, like permanent magnet motors. Photo Credit: Trelleborg Sealing Solutions.

In induction motors, conductors such as copper or aluminum are wound or embedded within the rotor’s steel laminate cylinder, and the stator’s AC current induces the rotor’s magnetic field. A permanent magnet rotor, on the other hand, generates its own magnetic field by either encasing or bonding permanent magnets to the rotor.

PMMs are inherently more efficient than induction motors because the induction rotor consumes electric power to generate its magnetic field while the PMM rotor does not. PMMs also offer a high power density and torque density: Compared to an induction motor, a PMM can provide an EV’s targeted power and torque with a smaller, lighter weight motor — supporting the critical EV objectives of higher performance and greater driving range. PMMs also feature low noise generation, which is attractive to the EV market.

Design for efficiency

Trelleborg’s thermoplastic composite sleeve is fabricated from a continuous fiber-reinforced prepreg that is overwound directly onto the PMM rotor. The company’s manufacturing process, automated fiber placement (AFP) with in-situ consolidation, is capable of making sleeves suitable for EV PMMs and nearly any other PMM application. They range in size from a diameter under 2.5 centimeters all the way up to a sleeve for the 33-centimeter-diameter rotor of a prototype electric motor, designed for commercial single-aisle class aircraft propulsion.

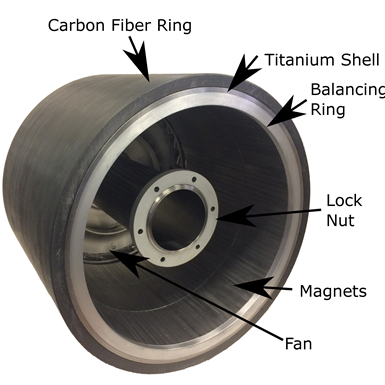

AFP/ISC for design. Trelleborg’s manufacturing process offers new design freedom — structurally stable thin overwinds and thick overwinds with no fiber waviness or buckling, for example. It also enables one-step manufacture of the composite PMM sleeves. Photo Credit: Trelleborg Sealing Solutions

For the high-performance requirements of an EV application, the sleeve is made from carbon fiber-reinforced polyetheretherketone (PEEK) prepreg tape. The materials and process for Trelleborg’s thermoplastic composite sleeve create advantageous design freedom compared to other materials and processes. Alternatives to the carbon fiber/PEEK sleeve include the thermoset composite version mentioned above, and a steel version. The properties of thermoplastic matrices, including their superior toughness and their resistance to wear, fatigue and chemicals, make them well suited to the harsh conditions that an EV drivetrain experiences.

Thinness is one key advantage of the Trelleborg design and process. The rotor sleeve adds distance between the rotor magnets and the stator, and the larger this gap, the lower the motor’s electromagnetic power and efficiency. This means that the ideal sleeve offers high strength in as thin a structure as possible. Trelleborg’s design produces a sleeve that is both thinner than can be fabricated from thermoset composites and stronger per unit thickness than can be produced with steel. Trelleborg program manager, Graham Ostrander, expects that sleeves for EV motors will be five to 20 plies thick.

Another important performance characteristic is the much lower electrical conductivity of carbon fiber-reinforced composites as compared to steel. Low conductivity reduces interference with the magnetic field. The combination of thinness and low conductivity helps the carbon fiber/PEEK sleeve to maximize the PMM’s power density.

Because rotors spin at very high speeds, the sleeves must also be designed in a way that prevents radial forces from causing fatigue or sudden failure. The rare earth metals that comprise the permanent magnets are brittle, and so stress reduction on the magnets during spinning is critical to the PMM’s performance and durability. The vast majority of the plies for the rotor application are 0° (hoop angle) to handle these radial forces, but axial reinforcement (90°) may also be incorporated as needed to increase bending stiffness. (Trelleborg’s AFP machine is capable of laying down prepreg tape, from 3 to 25 millimeters wide, at any angle.)

Raising throughput. The AFP/ISC technology can accommodate simultaneous overwind of multiple rotors. Instead of one long cylindrical component as seen here, the machine would line up the rotors end to end and be programmed to wind the rotors all at the same time. Photo Credit: Trelleborg Sealing Solutions

Key to withstanding the radial forces is pretensioning the composite material — Trelleborg’s current AFP machine is capable of up to 0.5 metric ton of tension (possible only with continuous fiber prepregs). “This pretension creates a hoop stress that acts as a compressive stress, keeping the composite sleeve in place over top of the item being overwound,” Ostrander says.

“The composite’s high tensile strength allows the rotor to spin at a much higher speed than any adhesive can hold,” he adds. Carbon fiber’s low coefficient of thermal expansion (CTE) also factors into the strong mechanical bond between sleeve and rotor, as does its light weight, which handles rapid acceleration and deceleration well.

The desired rotational speed of the rotor and the weight of the magnets together dictate the tension required. “Pretensioning the wind retains the sleeve on the rotor across a broad range of temperatures — a rating of -40°C to 80°C,” Ostrander reports.

Manufacture for design

In recent years, the engineering community has often pursued “design for manufacture” — making adjustments to a product’s design so that it can be manufactured more easily, more quickly, and/or more cost efficiently. In the case of PMM sleeves, however, one might characterize Trelleborg’s process as “manufacture for design,” or even “manufacture for design for manufacture.” That is, Trelleborg engineers developed a manufacturing approach that has reduced some constraints on product design; and this design freedom has in turn enabled a more efficient manufacturing workflow.

Aerospace application. As Trelleborg continues developmental work with EV manufacturers, the company has already helped in proof of concept research for 737-class electric aircraft. The PMM rotor here, with a carbon fiber/PEEK sleeve, was created and tested by NASA-funded researchers at the University of Illinois. Photo Credit: University of Illinois Urbana-Champaign

Trelleborg’s AFP can be used with either thermoset or thermoplastic composite prepreg, but of course in-situ consolidation is used only with thermoplastics. For the sleeve application, consolidation is performed using a laser heating system, which enhances the speed and efficiency of the process compared to conventional hot gas torch (HGT) heating.

One important feature of this process is the localization and short duration of heat application. High temperatures would demagnetize the rotor, rendering it unusable. “Even though we are using high heat to melt the polymer together, the heat is only applied for a very, very short amount of time,” Ostrander explains. “Our process does not increase the net temperature of the part we are overwinding more than a few degrees Celsius.”

Overwinding of the thermoplastic composite sleeve is performed directly on the magnetic rotor surface. “We have a special process that allows us to place the composite material on the part and make it stay in place without any adhesive or bonding to the surface of the part,” Ostrander emphasizes. The deposition head heats both the material it is laying down and the substrate beneath (initially the rotor surface in this application, then previously placed plies) and applies pressure while the resin is molten. This enables polymer chains to diffuse between the incoming tape and the substrate, creating a full bond.

The multiple passes of laser heat application — initially as the tape is first laid down, then reheating as the AFP goes over the area with subsequent plies — results in full crystallinity of the PEEK resin, maximizing its stability during use. Ostrander reports that temperature at the nip, where the incoming material is pressed against the substrate, is 450°C for carbon fiber-reinforced PEEK prepreg. PEEK melts at 343°C, and the nip temperature is typically set 60-120°C higher than the melt temperature. “The key is to stay below the degradation temperature of the polymer,” he says.

Spinning test. To verify analytical models of mechanical expansion, rotordynamics and rotating loss, the aircraft rotor prototype was tested inside a spin pit (for safety). The rotor performed successfully while spinning at 18,000 revolutions/minute, which is 20% faster than the intended operating speed. Photo Credit: University of Illinois Urbana-Champaign

Consolidating thermoplastic composites in-situ enables Trelleborg to overwind the PMM sleeve on the rotor in a one-step operation. Structures made with this manufacturing approach require no secondary oven or autoclave consolidation and typically achieve fiber volume of about 60%. “Once the part is done being wound, it is complete and ready for final machining,” Ostrander says.

“Our process allows us to combine a bunch of different manufacturing steps in one operation,” Hislop emphasizes. “This enhances the efficiency of the overall manufacturing process.”

In contrast, thermoset composite sleeves require a multi-step process. The thermoset version must be fabricated separate from the rotor because oven or autoclave consolidation would damage the magnets. After cure, these sleeves are pressed on or shrunk-fit over the rotor. This final step prevents the thermoset sleeve from being made as thin as the thermoplastic sleeve. “Since you don’t have to press the [thermoplastic] sleeve on the rotor [after cure], there’s no compressive load that would damage a thin sleeve,” Hislop explains.

The Trelleborg process has been used to make various kinds of composite structures, ranging in size from an inside diameter of 0.5 millimeter to an outside diameter of 150 centimeters. It has also fabricated stable structures as thin as two plies and as thick as 7.5 centimeters with no fiber waviness or buckling. Buckling can be a problem in thicker laminates fabricated with other consolidation methods, Ostrander says. “When you lay these materials in place, you wind up having air trapped in between the layers, but with in-situ consolidation, the air is squeezed out during the bonding process.” Coupled with the virtually unlimited outtime of thermoplastic prepregs, Ostrander concludes, “the in-situ consolidation process can be scaled up to make structures as large as airplanes.”

The indefinite outtime also enables the Trelleborg process to wind very long parts. In the case of the rotor sleeve, this capability means that a long chain of rotors can be set up in a line and wound all at the same time. “That way, we increase the throughput and decrease the overall cost to the customer,” Hislop says.

The attraction of PMMs

The cost of rare earth metals remains a detriment to the total cost of ownership of PMMs, and this fact, along with geopolitical tensions (China is the predominant supplier of rare earth metals), may slow the application of PMMs to EV series vehicles. But the appeal of PMMs remains strong because of their greater efficiency, torque and driving range when compared to induction motors. Last year, Reuters reported numerous efforts by major automakers to reduce their reliance on rare earth metals. It appears that most are doing so by finding alternative materials for permanent magnets, rather than switching to induction motors.

Whether through alternative magnets or through an easier, less costly supply of rare earth metals, PMMs appear likely to be adopted by a growing number of EV makers. And advancements like Trelleborg’s thermoplastic composite sleeve promise to catalyze this market.

Related Content

Composites manufacturing for general aviation aircraft

General aviation, certified and experimental, has increasingly embraced composites over the decades, a path further driven by leveraged innovation in materials and processes and the evolving AAM market.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreJeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

Read MorePlant tour: Teijin Carbon America Inc., Greenwood, S.C., U.S.

In 2018, Teijin broke ground on a facility that is reportedly the largest capacity carbon fiber line currently in existence. The line has been fully functional for nearly two years and has plenty of room for expansion.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More