Biomimicry braiding for load-bearing slender FRP node structures

An interdisciplinary research team has developed a spatially branched, carbon fiber-reinforced, high load-bearing supporting node for consideration in building and construction.

Concrete support node with carbon fiber-reinforced plastic hull. Photo Credit: Larissa Born, University of Stuttgart (ITFT), Institute for Textile and Fiber Technologies

An interdisciplinary research team from the University of Stuttgart (ITKE, ICD and ITFT) and the German Institutes of Textile and Fiber Research (DITF, Denkendorf) has developed a spatially branched, braided, carbon fiber-reinforced, high load-bearing supporting node as well as a process for manufacturing such complex structures. The biomimicry-inspired fiber-reinforced plastic (FRP) research and development is being carried out within the DFG-funded TRR-141 “Biological Design and Integrated Structures” in cooperation with the University of Freiburg (Germany).

“Weight is hardly a consideration in building and construction” according to Adriaan Beukers and Ed van Hinte, authors of “Designing Lightness” (2020). “Heaviness happens to be a traditional quality that comes with a gut feeling of trustworthiness and pride.” With an estimated 41% of global energy consumption attributed to buildings and structures according to the Energy and Environmental Building Alliance (EEBA, Plymouth, Minn., U.S.), there is a growing movement towards materials that can lighten the impact in every sense. Fibers, textiles and composites in particular are said to be growing in importance for the sector with a projected growth from $45 billion in 2017 to an expansion of more than 4.5% CAGR by 2025 (Global Markets Insights).

Moreover, according to Dr. Marie O’Mahony, an industry consultant, visiting professor at the Royal College of Art (RCA, London, U.K.), public and private buildings with open, wide and light spaces have an identified need for a supporting structures with branched columns to minimize the number required and the ground space they occupy. Similarly, in bridge construction, slender-branched load-bearing elements enables aesthetically pleasing and resource-saving constructions that perform very effectively in load distribution. The technical challenge of branched load-bearing structures is the connecting component, or structural node, between the straight members which is subjected to complex forces.

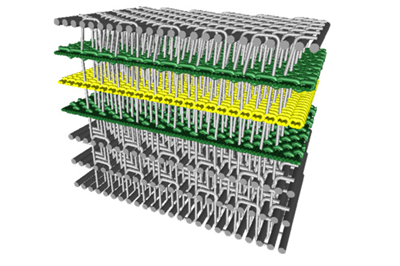

Branched, braided supporting structure consisting of node elements and straight supports. Exhibited at Construction Bionics Natural History Museum, in Stuttgart. Photo Credit: University of Stuttgart (ITKE), Institute of Building Structures and Structural Design

In this project, high-strength carbon fibers, used in synergy with concrete, are precisely aligned and arranged in order to maximize their mechanical properties. According to the research team, concrete is good at transferring the compressive forces that occur, while the outer FRP hull absorbs the tensile or bending stresses of the load-bearing nodes.

The fiber preform is produced using a braiding process. With the radial braiding machine used, up to 216 threads are braided simultaneously to produce a 3D textile with three fiber directions. The braiding threads inserted in the circumferential direction of the core geometry primarily form the dense cover for the concrete casting. Acting as a confining agent, the fibers force a multi-axial stress state, increasing the compressive strength of the concrete. The filler threads oriented in the axial direction mainly dissipate the tensile forces occurring during bending loads. The textile preform is then impregnated with a thermosetting polymer and consolidated into the solid FRP hull. Researchers found that the structure is dimensionally stable and can be used as a casting mold into which the concrete filling is poured.

One of the key challenges addressed by the team has been the development of a digitized workflow to reduce the time taken in setting up the process, such as the time-consuming process of programming the mandrel path through the braiding machine and the fiber placement, which is also a barrier to commercialization. With the development tool, the research team notes that it is possible to define the mandrel path through the braiding machine in a virtual braiding environment location, enabling considerable setup time to be saved. In this way, large and geometrically complex structures such as branched, 3D components can be produced with a continuous fiber reinforcement.

Moreover, the principles of biomimicry have been used to analyze the plant-branching effect for efficient load transfer, orientating the high-strength carbon fibers and developing the manufacturing process for the load-bearing node. Because the difference in the manufacturing effort for changing the geometric configurations of the node geometry is so slight, the process offers the architect, engineer or designer great freedom of design at a relatively low cost in time and money.

While already offering many possibilities, this biomimicry-inspired composite looks set to inspire whole new structure in the future. The four-arm node will be exhibited during JEC World 2022 from May 3-5 at the Innovation Planet “Building & Industry.”

Related Content

Improving carbon fiber SMC simulation for aerospace parts

Simutence and Engenuity demonstrate a virtual process chain enabling evaluation of process-induced fiber orientations for improved structural simulation and failure load prediction of a composite wing rib.

Read MorePlant tour: BeSpline/Addcomp, Sherbrooke, QC, Canada

Composites automation specialist increases access to next-gen technologies, including novel AFP systems and unique 3D parts using adaptive molds.

Read MoreASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

Read MoreOptimized approach to predict delamination failure in CFRTP structures

ARRK Engineering and Mitsui Chemicals improved delamination prediction accuracy to help optimize absorbed energy/failure load for an overmolded TAFNEX CF/PP UD tape bumper beam.

Read MoreRead Next

Smart, self-powering composite from DITF uses a "textile power plant" concept

Multilayer fabric-based piezoelectric elements and pyroelectric energy harvesters reinforce the FRP structure, generating electrical energy using vibration, oscillation and temperature fluctuation.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More