Carbon Conversions partners with motorsports shop Vermont SportsCar

To incorporate more environmentally conscious practices into its manufacturing processes, VSC is working with Carbon Conversions to reclaim, recycle and reuse its carbon fiber materials.

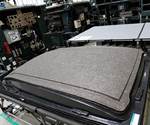

Photo Credit: Vermont SportsCar

Carbon fiber recycling company Carbon Conversions (CCI, Lake City, S.C., U.S.) has announced a partnership with Vermont SportsCar (VSC, Milton, Vt., U.S.) in helping VSC achieves its sustainability goals. A premier rally car prep shop in North America, VSC is reported to be the world’s largest Subaru Motorsports program. Along with CCI, VSC has started the process of “closing the loop” with various materials up to and including CCI’s re-Evo MCF nonwoven mat.

“VSC shares the same vision and passion as CCI,” Keith Graham, VP of sales and business development, notes. “With our advanced materials utilizing recovered carbon fiber from their waste stream, together we can push the boundaries of technology to create high-performance and eco-friendly solutions.”

In CCI’s “close the loop” system, which aims to save on materials and reduce production cost, the company works with customers to reclaim, recycle and repurpose carbon fiber and find valuable ways to use it. CCI uses a distinctive technique to distill the material, free discontinuous carbon fiber and create a variety of products for nearly any application, including:

- Chopped carbon fiber: re-Evo HSC and re-Evo IMC

- Nonwoven carbon fiber: re-Evo MCF and re-Evo MCO

- 3-DEP: 3D preforms using various re-Evo carbon fiber products

“The VSC facility was built with sustainability in mind and we make best efforts to incorporate environmentally sound practices whenever possible,” VSC adds. “We are thrilled to be working with Carbon Conversions, which will allow us to divert our carbon fiber scraps from the landfill while providing material that we, and other customers, can use again.”

Related Content

-

TU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

-

Natural fiber composites: Growing to fit sustainability needs

Led by global and industry-wide sustainability goals, commercial interest in flax and hemp fiber-reinforced composites grows into higher-performance, higher-volume applications.

-

Plant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.