Carbon fiber-reinforced concrete accelerates in Germany

TU Dresden and C3 – Carbon Concrete Composite demonstrator aims to reduce concrete material use by 50% and CO2 emissions by up to 70%; Hitexbau touts high-volume automated production for carbon fiber textile grids.

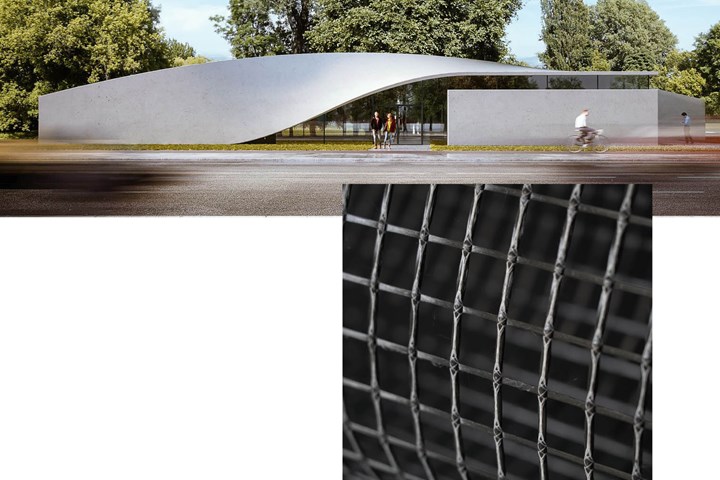

Rendering of CUBE building at TU Dresden and Hitexbau carbon fiber grid. Source | © Iurii Vakaliuk, HENN, TU Dresden and Hitexbau.

Technical University Dresden in Germany announced the onset of construction for its C³ tech demo house CUBE, locally known as Carbonhaus. TU Dresden claims the 220-square-meter, two-story building will be the world’s first building made entirely from carbon fiber-reinforced concrete.

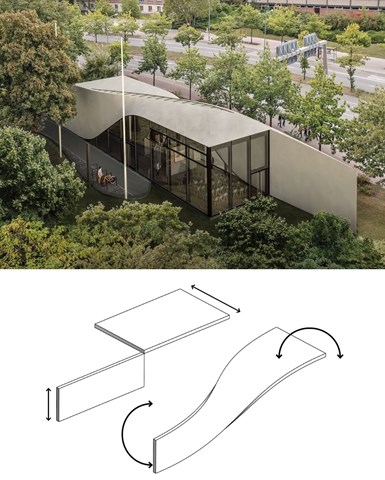

The CUBE showcases carbon fiber-reinforced concrete via a 24-meter-long seamless concrete wall and a “twist” combining wall and roof into a single, double-curved structure. Source | TU Dresden, HENN

Financed by the German Federal Ministry of Education and Research, the €5 million project started in 2017 and will culminate in spring 2021 in a university building comprising classroom, lab and presentation spaces. Though the foundations were poured in March 2020, further construction has only now resumed following a coronavirus-caused delay.

The design, refined by Munich-based architecture firm HENN, showcases the lightweight and formability of carbon fiber-reinforced concrete via its “twist” element and, as reported by John Caulfield in Building Design + Construction, a 24-meter length of seamless concrete wall.

The “twist” is formed from two shell-like elements that serve as wall and roof. The other main element is a split-level, precast box. Carbon fiber-reinforced concrete is used for both sections. Once completed, the building will be about 40 meters long, 7.2 meters wide and 6.9 meters at maximum height.

A rendering of the CUBE demonstrator inside looking onto the precast box element. Source | © Iurii Vakaliuk, HENN, TU Dresden

As described by TU Dresden Institute of Concrete Structures, the goal of this project is to show and demonstrate with a real structure that carbon-reinforced concrete is usable and practical.

New research center for carbon concrete

TU Dresden will continue further work with carbon-fiber reinforced concrete though a collaborative research center funded by the German Research Foundation (DFG, Bonn), as announced on June 6.

Dedicated to exploring new construction strategies using carbon fiber-reinforced

concrete, €12 million over 4 years will fund 26 researchers. They will pursue not only replacing previous steel-reinforced concrete but also develop new design strategies tailored to the properties of carbon fiber-reinforced concrete.

The project is led by long-time TU Dresden carbon fiber- and textile-reinforced concrete researcher, Dr. Manfred Curbach, and is titled, “Construction for the future: CRC/TR 280 Design strategies for carbon concrete structures using a minimal of material – Fundamentals for a new way of constructing.”

Partners include RWTH Aachen University (Aachen, Germany) and the Leibniz Institute of Polymer Research (IPF, Dresden). An excerpt from the project synopsis explains:

“Novel materials allow for new designs and new methods of construction. It sounds quite simple, but there is often a long way to go. In architectural engineering, innovation processes take a particularly long time due to high demands on safety and durability as well as complex standardization and approval procedures. This holds true even more so for high-performance building material combinations such as textile-reinforced concrete and carbon concrete, which will bring about a paradigm shift if not a revolution in building with concrete, the most important building material worldwide in terms of volume.

“Using carbon concrete can significantly reduce both the enormous consumption of resources and the CO2 emissions of the construction industry, at the same time giving access to additional functions. However, first construction projects have demonstrated that despite the novel possibilities, … the conventional materials are simply being substituted. The full potential of the innovative carbon concrete composite material will only be realized in the future if it will be combined with intelligent design strategies.

C³-Carbon Concrete Composite won the German Sustainability Award 2015. C³ consortium member VDZ (Düsseldorf) assisted in research designed to eliminate market barriers by creating the foundation for clear regulations (based on DIN Technical Report 100) to establish carbon fiber-reinforced concrete in German construction practice. Source | ©Ulrich van Stipriaan, C³-Carbon Concrete Composite and VDZ

“Profound fundamental research as well as a holistic approach are the prerequisites for finding suitable methods for the designing, modelling and projecting with novel construction materials. For carbon concrete composite, this implies lightweight construction principles adapted to the material. … The development of novel structures is closely linked to issues of manufacturability, taking into account both an accompanying product-related sustainability assessment and an adequate refinement of the composite itself.

“The construction strategies that will prove to be effective will allow for completely different shapes. The new design strategies and material combinations will reduce resource and energy consumption due to previously unknown lightweight construction principles, while at the same time offering high suitability for use, structural safety and durability. Additionally, these new strategies and composites are reflected in ambitious aesthetics, which may develop into a new 'art of constructing.'”

Carbon fiber for concrete reinforcement in large volumes

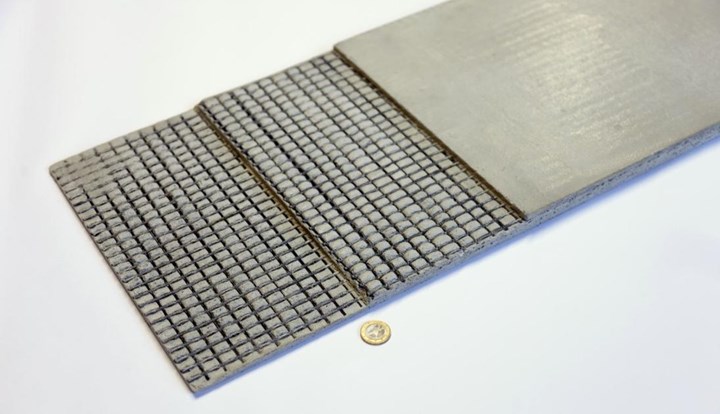

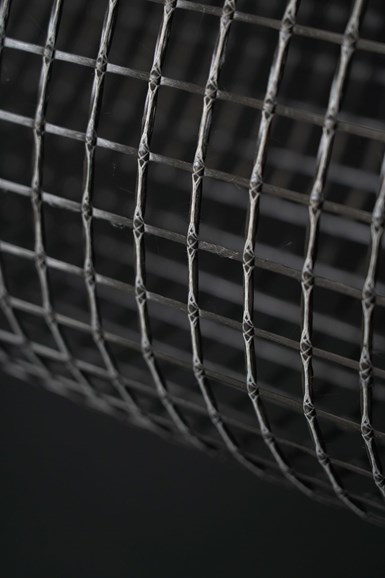

Carbon fiber lattice grid for reinforcing concrete, produced by Hitexbau. Source | Hitexbau

The news story “Concrete reinforcement made of carbon in large volumes” was published in January 2020 by Breton and later in March by BFT International, a recognized trade journal for manufacturers of concrete and precast concrete products. Hitexbau (Augsburg, Germany) has developed a highly automated production line for carbon fiber reinforcements, enabling large dimensions as well as large volumes. Lattice grids are available as rolls or sheets and reportedly make it possible to use concretes with a large grain diameter of up to 16 millimeters.

In combination with special coatings of the textile reinforcement structures and with different concrete formulations, Hitexbau claims these reinforcements enable concrete with a peak compressive strength of 3,300 newtons per square meter.

Since 2015, Hitexbau has worked in close cooperation with both TU Dresden and RWTH Aachen to develop carbon fiber textile reinforcements for the building and construction industry. In addition to supplying reinforcements, it offers product development and laboratory testing.

Editor’s note: Altus Group (Greenville, SC, US) is an alliance of precast concrete manufacturers that brings innovative technologies to the construction market. As of 2017, its members had completed more than 1,400 projects using CFRP-reinforced CarbonCast technology, totaling 40 million ft2 (3.7 million m2). Please read about the CarbonCast technology, developed with Chomarat North America (Williamston, SC, US) using its C-GRID product in the 2017 article: “Higher performance in precast concrete with CFRP”.

Related Content

Sulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

Read MoreBio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.

Read MoreASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

Read MoreWelding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

Read MoreRead Next

Higher performance in precast concrete with CFRP

C-GRID trusses in CarbonCast wall system cut construction time, cost, complexity and carbon footprint in energy-efficient urban student housing.

Read MoreReinforced concrete incorporated into sustainable building design

A Chicago apartment complex uses glass fiber-reinforced concrete facade cladding as part of its climate-friendly construction.

Read MoreCOMPOSITES AND CONCRETE

The benefits of composite materials are well established in concrete reinforcement and construction.

Read More

.jpg;maxWidth=300;quality=90)