Precast concrete is a construction product made by curing concrete in a reusable mold or form. Produced in a controlled factory environment, precast concrete can be closely monitored during cure, resulting in a higher quality product than can be provided when concrete is poured and cured in job-specific forms at construction sites. This offsite production also enables wider design possibilities, including use of lightweight, high-strength concrete mixes, foam-core insulation in precast panels and reinforcement with steel or synthetic materials. These options allow for longer spans, a reduced number of supports and thinner panels, which contribute to reductions in weight and cost.

A precast plant can reuse its concrete forms hundreds to thousands of times, which also helps to reduce cost. Onsite complexity is reduced as well, as is the construction schedule because manufacturing of the precast elements can begin while the building foundation is prepared. Manufactured off-site, precast elements can be stored, then transported to the construction site and installed as needed. Precast concrete is commonly used today in bridges, parking structures, office buildings, arenas, manufacturing and storage facilities, high-rise apartments and other residential structures, as well as commercial and public municipal buildings.

In 2004, Altus Group (Greenville, SC, US) introduced CarbonCast technology into North America, enabling even further weight and cost benefits, thanks to the use of carbon fiber reinforcement. An alliance of precast concrete manufacturers that brings innovative technologies to the construction market, Altus Group worked with Chomarat North America (Williamston, SC, US) to use its carbon fiber/epoxy C-GRID as a shear truss in precast concrete panels, creating a precast wall system that is lighter, thinner and stronger than most cast-in-place concrete, solid precast concrete and conventional steel-reinforced precast concrete wall systems. Because carbon fiber is much stronger than steel, panel size can be increased, meaning fewer pieces are produced and transported, so installation is faster and the overall carbon footprint during construction is smaller vs. conventional precast.

With more than 1,400 CarbonCast projects completed to date, totaling 40 million ft2 (3.7 million m2), Altus Group members see continued growth for C-GRID panels and structures as a solution to increasing demands for efficiency and performance in construction. CW explores why and how through a recent project with serious cost and schedule challenges: the Georgia State University (GSU) Piedmont Central student housing in downtown Atlanta.

Preparing the winning bid

“The student housing market is very large and increasing its use of precast concrete,” says John Carson, managing director for Altus Group. He explains that this type of project typically begins with an owner (e.g., college or university), an architect that has design responsibility for the project and/or a general contractor. The latter will help to define construction of the building envelope as part of the design process. Quite often, the owner/architect/contractor team will proceed through a design-assist model of development, where the precast manufacturer also is included, to help optimize the number of precast elements, which affects cost. The precaster also plays a large role in scheduling and determining how the finished elements are erected.

The GSU Piedmont Central project was one of seven campuses receiving housing through a public/private partnership (P3) between The University System of Georgia and the private developer Corvias Group (East Greenwich, RI, US). After a competitive bid process, the Piedmont Central project was awarded to the team of Choate Construction (Atlanta, GA, US), architecture firm Cooper Carry & Associates Inc. (Atlanta, GA) and precast manufacturer Metromont (Greenville, SC, US).

“GSU is interesting because it is an urban campus,” explains Tim Fish, architect and principal at Cooper Carry. “It actually had very little housing, but now has the largest student body in the state. This project was part of that growth.” The urban setting meant space was at a premium. “The building would occupy 1 acre on the 1.4-acre site, so there was no room for staging materials,” notes George Spence, business development manager at Metromont. The team decided early on to transfer labor to the Metromont plant. “In that way,” he adds, “only one contractor would be on site to erect the walls and no space would be required for storage and staging. Trucks would simply pull up to the site and the precast panels would be installed directly.”

Another issue was cost. “The university was determined to maintain its affordability for students,” says Fish. This meant the new dorm building had to be economical and stay on budget. And then there was the schedule. “We had one year from pouring of the foundation to student move-in,” says Spence.

Cooper Cary began working with GSU and other team members on the building design. “We began with trying to make the building blocks of the project, the residential units, as efficient as possible,” Fish recalls. This was important for the 253,843-ft2 (23,583m2) project comprising 1,152 beds in 320 suite- and semi-suite-style dorm rooms.

“Beyond that, we tried to create space for varying levels of social engagement on every floor, and we also had to create the 400-seat dining hall on the entry level, but without a lot of structural gyrations in order to meet the cost target.” Actually, the building skin was the structure, so materials were very important. “The structure had to be buildable, but also provide the desired aesthetic. We wanted to make it fit in with downtown Atlanta, but also have an identity within GSU.” He explains that the university sees each building as a way to reinforce its brand, which is a mix of modern and traditional. “A lot of demands were unfolding simultaneously,” says Fish, “and precast has a unique ability to provide a solution.”

The GSU Piedmont Central project was designed as an entirely precast building — all of its elements would be precast concrete. “This speeds construction by at least 15-25%,” says Carson. The CarbonCast-based design features loadbearing wall panels with a brick and sandblasted concrete exterior finish. Thermally efficient, the insulated wall panels have an R-value that exceeds the energy code with painted back sides that provide the interior finish. All wall system requirements were met in one precast panel, versus several passes around the building (and use of subcontractors) to perform individual framing, insulation, interior-finish, air/moisture barrier, waterproofing and exterior finish. “This CarbonCast construction is everything you want in a wall system: airproof, waterproof, moistureproof,” notes Spence, “and it eliminates $7/ft2 [$75/m2] worth of studs, framing and insulation.”

Light weight, high insulation

C-GRID was developed to replace the welded metal wire mesh in concrete structures and prefabricated panels. It is made from 24K and 50K carbon fiber tows, which are assembled perpendicular to each other into a grid, using a continuous rotary-forming process that chemically binds them with a tough, heat-cured epoxy resin. In the CarbonCast wall system, C-GRID is a key component of the overall composite panel design.

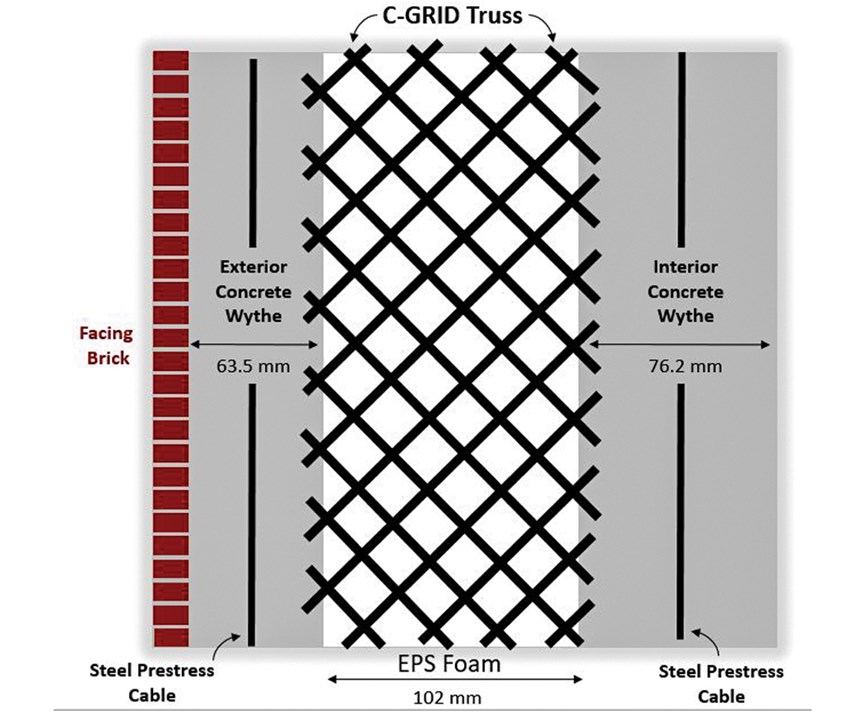

CarbonCast insulated wall panels use foam insulation sandwiched between two concrete wall sections called wythes (Fig. 1). Spence explains that C-GRID “acts as a truss, holding the front and back faces of the wall panel together, which is very efficient structurally.” For example, a 9-inch (229-mm) thick CarbonCast insulated wall panel, with 3-4 inches (76-102 mm) of foam, and held together with C-GRID trusses behaves as if it were a 9-inch thick solid concrete panel. “But the C-GRID can make the panels 40-50% lighter,” he adds. “It’s cheaper to supply C-GRID panels to the job site vs. heavier, solid panels, and we can get two to three more C-GRID panels per truckload.”

Thermal performance also is a benefit. Carson touts the higher insulation values of C-GRID panels, which reduce a building’s energy use and carbon footprint. “Another big advantage of C-GRID is no thermal bridging,” says Spence. Thermal bridging occurs when a building’s insulation is breached because heat or cold is conducted to its exterior via metal-to-metal contact between fasteners and other components. “C-GRID prevents this because it is not metal and, therefore, does not interrupt the foam insulation performance or conduct temperature in or out of the panel.” He adds that continuous insulation is a requirement in most building codes today. There also are no voids or cavities to support mold growth, and the C-GRID panels provide inherent corrosion resistance and fire resistance without additional layers or concrete additives.

Fast-paced production

With the design and construction approach determined, Metromont worked with Cooper Cary and the Engineer of Record (EOR) to optimize panel sizes, aiming for the fewest number of panels that would satisfy building code requirements. During this final phase of design, each piece in the building was engineered to carry its required load and its connections were detailed, both to the structural frame and to other precast elements. “Once the construction drawings were approved, we were released to start production,” says Spence. “This was roughly two months before they would be ready for us on the job site.”

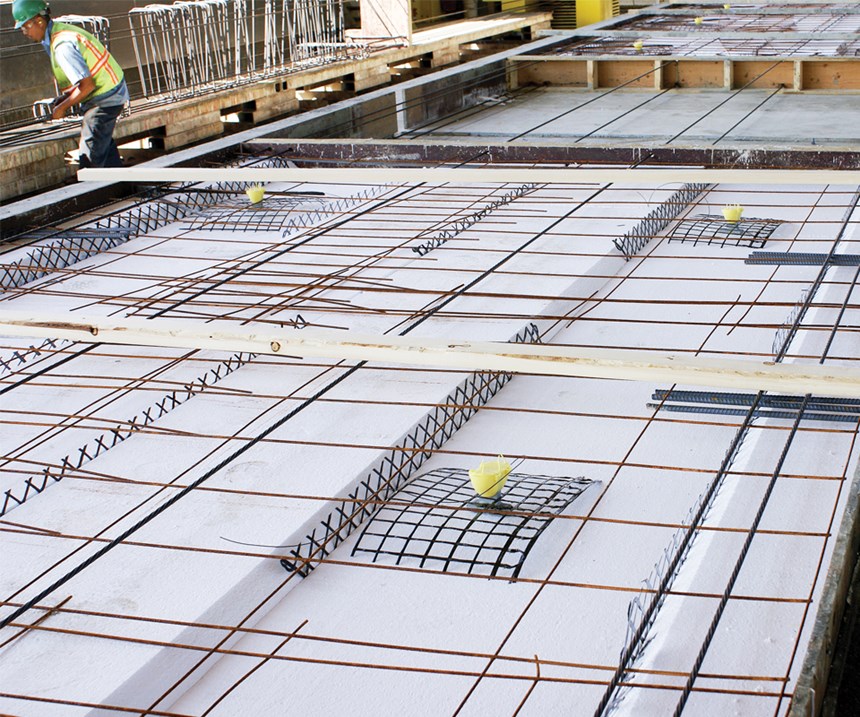

When production began at the Metromont precast plant, each wall panel was made using basically the same steps. “The panels were 12 ft [3.7m] tall because they span from floor-to-floor in the building and, for this project, range from 24 to 44 ft [7.3-13.4m] in length,” Spence explains. The exterior face of each panel was poured first. “It used a 2.5-inch [63.5-mm] thick architectural mix concrete poured on top of 0.625-inch [15.875-mm] thick facing bricks used for exteriors, which had already been set face down in a mold,” he continues. Next, 4-inch /102-mm thick expanded polystyrene (EPS) foam boards were placed on top (Step 1). Strips of C-GRID were then placed vertically next to and in between the EPS foam boards at regular intervals, plunged 0.75 inch/19 mm down into the wet concrete (Step 2). Their tops would extend into the final pour of concrete. “These connect the exterior wythe to the interior wythe, which will be poured next,” notes Spence.

Before the final concrete pour, prestressed cables and some conventional steel reinforcements (see black and brown strands, respectively, in Step 3) were placed on top of the EPS foam. (These also were used in the previously poured exterior wythe and were part of the approved design for these loadbearing walls.)

Plastic covers (the yellow “cups” visible in Step 3) for lifting inserts that enable crane installation of the panels were also placed, each anchored with a square of C-GRID. Finally, the 3-inch /76.2-mm thick interior concrete wythe was troweled on (Step 4). The Metromont production crew could make one panel in about an hour. The panels then cure until the concrete reaches a stripping strength — strength at which formwork can be removed — of 4,000 psi, which takes roughly 10 hours. The panel forming bed is then set up to cast again the next day.

Spence explains that where the C-GRID trusses are placed is defined by the EOR, based on the wall system structural requirements and other considerations for each project. “Generally, the C-GRID shear webs are placed 2 ft [0.6m] apart,” he notes. Non-loadbearing walls require fewer C-GRID connections, so they can be spaced further apart. For the GSU project, however, every panel was loadbearing.

As panels were completed, they were loaded onto trucks for just-in-time delivery to the job site. “We staged production to make sure that erection of the walls and floors proceeded per the plan,” says Spence. At the building site, panels were lifted with a crane and set into place (Step 5). “There were metal plates or angles embedded in the vertical wall panels and horizontal floor panels,” Spence explains. “These were welded together to form the wall-to-floor connections. The resulting box structures comprise the building. When the welding was finished, structurally, the building was complete.” He notes that a final layer of concrete was poured on top of the installed floor panels to cover the welded connection details.

The precast structure — including 1,803 pieces and 200,670 ft2 (18,643 m2) of C-GRID panels — was erected in five months by a six-man crew. “After about one month into this process, Choate began bringing in other trades,” says Spence. This allowed the contractor to jumpstart installation of electrical, plumbing and interior finishing systems (Steps 6 & 7) in order to complete the dormitory for the start of the 2016 school year.

Continued drive for efficiency

The GSU Piedmont Central dorm is just one example of the CarbonCast system’s success based on C-GRID. “We’ve converted all of our vertical wall panels to this system,” says Spence.

“We just finished building apartments in Tampa, Florida, using these panels,” he adds, “because C-GRID walls can withstand 200-mph hurricane winds. That is a tough building code requirement to meet,” he points out, noting, “You can do it with solid concrete, but it’s heavy and expensive.”

The CarbonCast system also is a plus in the booming digital world. “We build a tremendous number of data centers, and C-GRID is used in the precast walls to meet the mandatory 180- to 200-mph wind load requirements,” Spence adds. The CarbonCast panels also meet data center conditioned space (heating/cooling/dehumidification) requirements. “I don’t quote a job with conditioned space, where I don’t specify C-GRID. The panels are cheaper and the energy costs are lower,” he explains, emphasizing, “The customer wins twice.”

But why must the fiber-reinforced plastic (FRP) composite be reinforced with carbon fiber? Wouldn’t glass fiber be more cost-effective? “There are other FRP forms that CarbonCast competes against, most being glass fiber-reinforced vinyl ester resin,” Carson replies. “But CarbonCast offers higher performance, enough that you can use significantly less concrete. There is also an advantage in how the CarbonCast system uses the C-GRID vs. how other FRP elements are used in competing wall systems.”

This last point is part of the unique relationship between Chomarat as the C-GRID manufacturer, Altus Group, the CarbonCast technology licensor, and the precast manufacturer members of Altus Group as CarbonCast licensees. “All of our members which use CarbonCast use the same design engineering protocol and manufacturing guidelines,” Carson explains. He adds that Chomarat’s manufacturing process for C-GRID is unique. It supplies the reinforcement trusses straight to each precaster. “It’s ready to use as delivered, and is one of the lowest-cost forms of carbon FRP [CFRP] used for building/construction applications.”

“Composites, in general, offer a lot of flexibility in projects,” says Cooper Carry’s Fish, citing a current project where FRP is being considered to reinforce a building that must be supported during partial demolition because it is lightweight yet stronger than steel. All of the GSU Piedmont Central partners agree that the demand for speed, efficiency and performance in building and construction will continue to increase. According to industry reports, this will drive continued growth in precast concrete’s share of the overall construction market, and continued opportunities for C-GRID and CarbonCast.

Related Content

Gatorbar, NEG, ExxonMobil join forces for composite rebar

ExxonMobil’s Materia Proxima polyolefin thermoset resin systems and glass fiber from NEG-US is used to produce GatorBar, an industry-leading, glass fiber-reinforced composite rebar (GFRP).

Read MoreCCG FRP panels rehabilitate historic Northamption Street Bridge

High-strength, composite molded, prefabricated panels solve weight problems for the heavily-trafficked bridge, providing cantilever sidewalks for wider shared use paths.

Read MoreCirculinQ: Glass fiber, recycled plastic turn paving into climate solutions

Durable, modular paving system from recycled composite filters, collects, infiltrates stormwater to reduce flooding and recharge local aquifers.

Read MoreComposites end markets: Infrastructure and construction (2024)

Composites are increasingly used in applications like building facades, bridges, utility poles, wastewater treatment pipes, repair solutions and more.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More