CarboScreen project to develop multimodal, sensor-based monitoring of carbon fiber production process

January 2023 CarboScreen project seeks to improve carbon fiber yield, reduce cost and improve properties.

Share

Read Next

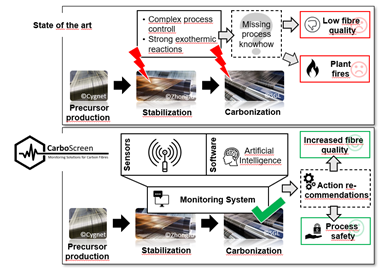

Reinforcing fibers such as carbon fiber can only develop their full potential if the fibers are not damaged during production and processing. However, optical monitoring of the processes according to the current state of the art is not sufficient to detect structural defects during most fiber production processes.

This deficit is particularly evident in the complex carbon fiber manufacturing process. Currently, no sensor systems are commercially available for monitoring the quality of carbon fibers as they are being manufactured. This results in the risk of reduced fiber quality and, in extreme cases, plant fires.

In order to guarantee sufficient product quality, the maximum production speed is often limited to roughly 12 to 15 meters/minute. The current production potential of these carbon fiber production lines, therefore, is significantly reduced — in some instances, the use rate is only 30-40%. As a result, the selling price for carbon fibers, at an average of €20/kilogram, is well above the acceptable costs for mass applications.

Funded by the German EXIST-Forschungstransfer (research transfer) program, the CarbonScreen project will include development, production and sale of a multimodal, sensor-based monitoring system to carbon fiber manufacturers to improve carbon fiber yield, reduce cost and improve properties.

In addition to mechanical fiber damage, the system will also monitor relevant parameters such as the degree of fiber stabilization inline. At the heart of this solution is the adaptation of various sensor systems to the carbon fiber manufacturing process and the development of an AI-based software platform. The software platform links the measured sensor data with process know-how to derive and deliver recommendations for action to the plant operator.

The combination of sensor, fiber and process know-how to derive recommendations for the customer is the expertise of the project leaders. Start of the CarboScreen project is planned for January 2023. For more information, contact Felix Pohlkemper, researcher at the Institut für Textiltechnik (ITA) at RWTH Aachen University (Aachen, Germany).

Related Content

-

SAM XL demonstrates closed-loop digital methodologies via full-size aerocomposite parts development

PeneloPe Project’s modular, zero-defect manufacturing deliverables are being highlighted in an upcoming video that demonstrates the resulting aerospace pilot line’s feasibility.

-

Aerotech Academy Puglia is inaugurated at Leonardo Aerospace site in Grottaglie, Italy

Joining the Leonardo MaTeRIA Lab and Joint Lab with Syensqo, this aerostructures training course will be 75% materials science and structural design/analysis, 25% digital transformation and AI.

-

Next-gen composites manufacturing: Combining material, machine and mold cavity data with analytics

Using a sensor, an edge device and machine learning software, sensXPERT sees into processes and is improving quality and cutting scrap, cycle time and energy use for composites customers like ZF and Carbon Revolution.