CEAD grows large-scale 3D printing presence with new facility opening

From garage startup to global 3D printing company, CEAD’s 3,000-square-meter facility, featuring Flexbot, extruders and more, opens up the potential for new R&D, partner collaborations and future company growth.

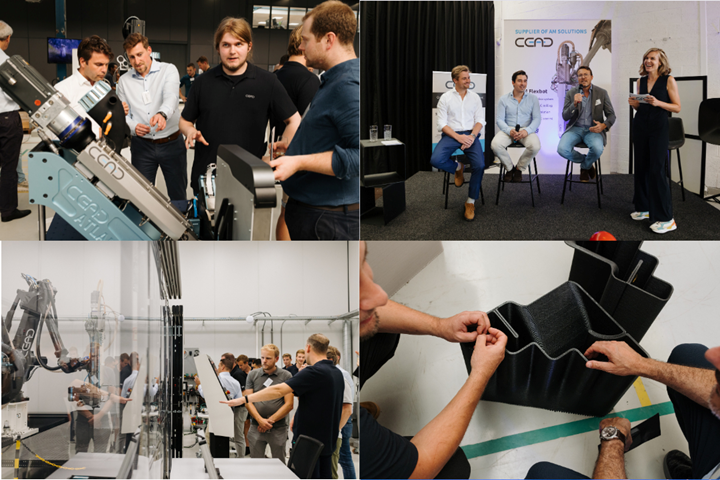

On Sept. 7, CEAD (Delft, Netherlands), joined by partners, unveiled a new 3,000-square-meter state-of-the-art facility, signifying the company’s journey from garage startup to its current position as a global large-scale 3D printing company.

In addition to acting as a collaborative R&D space with partners, the facility houses many of CEAD’s technology developments, including the presence of five substantial Flexbot setups and an extensive range of extruders. CEAD says there is still plenty of room left for future growth.

From the beginning

Nine years ago, two young visionaries, CEAD’s founders, CTO Maarten Logtenberg and CEO Lucas Janssen, started their journey within the walls of a garage in the middle of a residential area. Their dream was to design and build machines. However, the sounds of heavy machinery led them to relocate to a shop floor in Rotterdam. As their operations continued to expand, they outgrew each subsequent workspace, necessitating a series of moves that ultimately led to this opening event.

Over the years, CEAD has experienced its fair share of challenges and pivots. Initially, the company wrestled with the concept of “building machines which don’t exist,” a broad and ambitious vision which led to various interesting projects, but made it challenging for potential customers to find them due to a lack of one particular specialization. With limited resources and an unwavering determination, CEAD embarked on a transformative journey to redefine its focus and find a niche.

With prior experience in consumer desktop 3D printing from LeapFrog, Logtenberg and Janssen decided to re-enter the 3D printing world, this time focusing on the business-to-business market. With their team’s support during somewhat uncertain times and the trust of their first official customer, Jan Schrama from PolyProducts, CEAD launched the CFAM Prime 3D printer.

It was quickly realized that for full market adoption, the technology required more adaptability than the cartesian gantry system could deliver. In 2019, CEAD introduced the Flexbot, a flexible and scalable robot-based system that met the diverse needs of the company’s expanding clientele. Within a few short months, the first Flexbot was operational and by year end, CEAD celebrated its first international sale to TU Munich (TUM). The journey was one of continuous learning, a testament to the cofounders’ and team’s resilience and ability to create a new niche in an evolving market.

A successful event

CEAD’s achievements brought a diverse audience of approximately 400 attendees, including development partners, hardware and software suppliers, material suppliers and local support partners to the event. It also attracted the esteemed presence of His Royal Highness Prince Constantijn van Oranje-Nassau, ambassador of TechLeap. Constantijn van Oranje-Nassau has worked tirelessly on boosting the Dutch innovation and tech scene. He expressed his admiration for the milestones CEAD has achieved, noting the rarity of the company’s growth without external funding.

“It’s not only about the machine and the technology,” Janssen says. “It’s also about implementing a turnkey solution to transform a production process into a more efficient and cost-effective process. Our customers continue to surprise us by printing parts in entirely new industries that we had not yet considered. For example, we would never have guessed our machines would be used to print Christmas decorations.”

Finding success in collaboration

An important aspect when fully adopting a new technology is collaborating with knowledge institutes and research universities. As an early adopter of the Flexbot, TUM performed crucial testing on the machine and helped validate many 3D printing materials. TUM is also now involved in the testing of the Advanced Tape Layer Additive Manufacturing (ATLAM), CEAD’s latest invention in collaboration with GKN Aerospace (Redditch, U.K.) (read “ATLAM combines composite tape laying, large-scale thermoplastic 3D printing in one printhead”).

Meanwhile, CEAD technology has been installed and is operational at numerous research facilities around the world. Aside from closely collaborating with these universities and exchanging mutual feedback, CEAD has also allocated a significant portion of its new facility to R&D. Throughout the shop floor, CEAD engineers provided insights into various facets of the production and installation process, and current software developments, as well as explanations of the live demo prints that were running on two Flexbots.

The display of CEAD’s range of extruders, currently consisting of four different models, further underscores its commitment to anticipating clients’ needs by offering diverse solutions. At the partner island, various partners displayed their research, technologies and other exciting activities they’re engaged in. Hi Delta, Haagse Hogeschool + SAM XL, Brightlands Materials Center, TUM Carbon Chair of Composites and MX3D were present, enhancing Charléne van Wingerden (CCO) concluding speech noting that collaboration is what truly takes a new technology to the next level. Van Wingerden also expressed her gratitude to everyone in the AM community for their efforts and knowledge-sharing.

Today, CEAD boasts a workforce of 65 employees and interns. With an ever-deepening understanding of its market, more than 120 machines installed worldwide, great partnerships and the company’s own personal growth, CEAD stands stronger than ever before.

Read Next

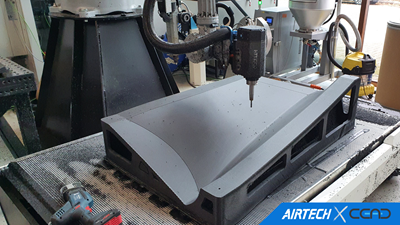

CEAD qualifies Airtech Dalhtram resins for use on all AM Flexbot platforms

Combination of the robot-based system with Airtech’s extensive resin line will enhance composites AM production and performance flexibility across multiple industries.

Read MoreJoby selects Dayton, Ohio, for first scaled eVTOL manufacturing facility

Located in the “birthplace of aviation,” Joby’s 2025 facility, led by state and local support, will deliver up to 500 aircraft per year with potential to reinforce further growth.

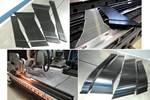

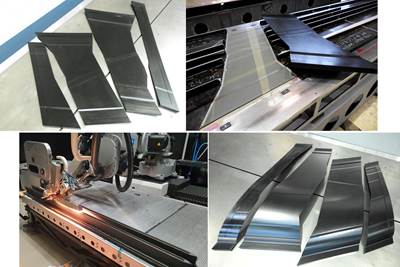

Read More3D-printed CFRP tools for serial production of composite landing flaps

GKN Aerospace Munich and CEAD develop printed tooling with short and continuous fiber that reduces cost and increases sustainability for composites production.

Read More