Joby selects Dayton, Ohio, for first scaled eVTOL manufacturing facility

Located in the “birthplace of aviation,” Joby’s 2025 facility, led by state and local support, will deliver up to 500 aircraft per year with potential to reinforce further growth.

Joby Aviation (Santa Cruz, Calif., U.S.) has announced plans to locate its first scaled aircraft production facility in Dayton, Ohio, U.S., the birthplace of aviation, from the Wright Brothers and their first airplane factory in 1910, to Wright-Patterson Air Force Base and the headquarters of the U.S. Air Force Research Laboratories, which has played a key role in supporting Joby’s development.

Joby plans to build a facility capable of delivering up to 500 aircraft per year at the Dayton International Airport, supporting up to 2,000 jobs. The 140-acre site it has selected has the potential to support significant further growth over time, providing enough land to build up to two million square feet of manufacturing space. Construction of the scaled Ohio facility is expected to start in 2024 and come online in 2025. Joby plans to use existing nearby buildings to begin near-term operations.

The state of Ohio, JobsOhio and local political subdivisions have offered incentives and benefits of up to $325 million to support the development of the facility, while Joby plans to invest up to $500 million as it scales operations at the site. Joby has been invited by the U.S. Department of Energy to submit a Part II Application for financing under the Title XVII Loan Guarantee Program, which provides access to low-interest loans for clean energy projects and would support the scaling of the facility.

Joby’s long-term investor, Toyota (Tokyo, Japan), that worked with Joby on the design and successful launch of the company’s pilot production line in Marina, Calif., U.S., plans to continue to advise Joby as it prepares for scaled production of its commercial passenger electric vertical takeoff and landing (eVTOL) aircraft in Ohio.

“We’re building the future of aviation right where it all started, in Dayton, Ohio,” JoeBen Bevirt, founder and CEO of Joby, says. “The Wright Brothers harnessed revolutionary technology of their time to open up the skies, and we intend to do the same — this time, bringing quiet and emissions-free flight that we hope will have an equally profound impact on our world. We’re grateful to Governor Mike DeWine, Lt. Governor Jon Husted, Senator Sherrod Brown, Senator JD Vance, Representative Mike Turner and the team at JobsOhio for their support, as well as the representatives of the many other states we worked with during this process. Our partnership with Ohio is a great example of how successful public-private partnership amongst industry, local, state and federal government can bring important new technology to life.”

Joby plans to start hiring in the coming months, with early roles expected to focus on the build out of the scaled facility and the machining of parts that will initially be incorporated into Joby’s California low-volume production line. Those interested in applying for roles at Joby’s Ohio facility can register their interest at www.jobyinohio.com.

Joby’s selection of Ohio as the site for its first scaled aircraft production facility followed an extensive competitive site selection process and is contingent upon standard due diligence, state and local approvals of incentives, permitting and other legal and regulatory matters as customarily accompany such investment projects.

The company’s headquarters, R&D and pilot production facility will remain in California (read “Plant tour: Joby Aviation, Marina, Calif., U.S.”). With approximately 150 open positions across the company’s three Northern California sites, Joby continues to grow its presence in the state.

Related Content

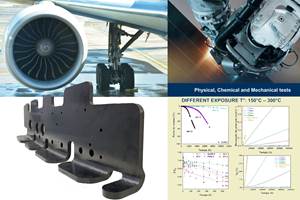

Daher CARAC TP project advances thermoplastic composites certification approach

New tests, analysis enable databases, models, design guidelines and methodologies, combining materials science with production processes to predict and optimize part performance at temperatures above Tg (≈150-180°C) for wing and engine structures.

Read MoreRecycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

Read MorePartners recycle A350 composite production waste into adjustable-length rods for MFFD

Herone, Spiral RTC, Teijin Carbon Europe and Collins Aerospace Almere recycle A350 thermoplastic composite clips/cleats waste into rods for the all-thermoplastic composite Multifunctional Fuselage Demonstrator’s crown.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreRead Next

OCSiAl to construct European graphene nanotube facility in 2024

Synthesized graphene nanotubes and other nanotube derivatives at new hub in Serbia will meet customer demand for high-performance EV batteries, polymers.

Read MoreGKN Aerospace, Joby Aviation sign aerostructures agreement

GKN Aerospace will manufacture thermoplastic composite flight control surfaces for Joby’s all-electric, four-passenger, composites-intensive ride-sharing aircraft.

Read MoreJoby marks production launch, receives permit to fly first eVTOL prototype

Joby has received a Special Airworthiness certificate for its first composites-intensive aircraft built at the company’s pilot production line built in close collaboration with Toyota, enabling flight testing to begin.

Read More