CEAD qualifies Airtech Dalhtram resins for use on all AM Flexbot platforms

Combination of the robot-based system with Airtech’s extensive resin line will enhance composites AM production and performance flexibility across multiple industries.

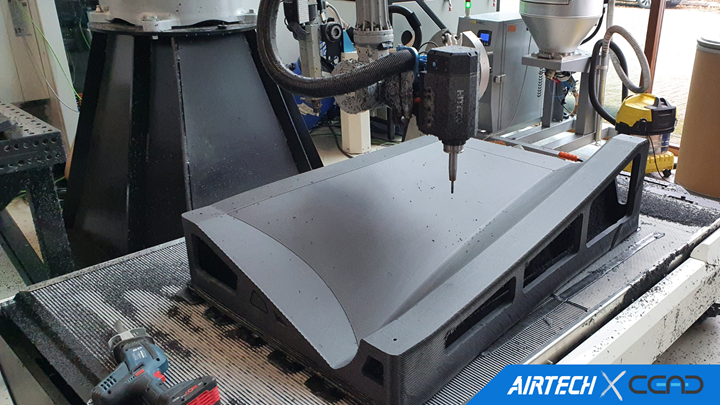

Photo Credit: Airtech, CEAD

In addition to expanded its offering of resins for use in additive manufacturing (AM) Airtech Advanced Materials Group’s (Huntington Beach, Calif., U.S.) Dalhtram resins have been qualified for use on all CEAD (Delft, Netherlands) robot-based AM Flexbot platforms. With exceptional process knowledge, application requirements and production performance, Airtech contends that this development offers breakthrough performance and unparalleled flexibility across industries.

The AM Flexbot, one of CEAD’s solutions for large-scale composite AM, uses Comau (Turin, Italy) robots directly controlled by Siemens’ (Waltham, Mass., U.S.) Sinumerik operating system. It offers the option to combine 3D printing and milling into one automated process and provides multiple options which can be integrated to configure the system to specific needs. This versatility makes it ideal for moldmaking and tooling applications, for example, when needing to achieve a required surface finish.

Airtech Dahltram resins are suitable for multiple print platforms, offering production flexibility with end-use material validation. Airtech reports that it has continued to demonstrate efficacy in composites fabrication with extensive autoclave cycle testing across various platforms with all materials offered. Providing extensive mechanical characterization data, Dahltram resins are well suited for composites fabrication, as well as metal fabrication and direct-to-part applications.

This partnership is the latest gain in Airtech’s continued effort to drive innovation, development and testing in the AM market.

Related Content

-

ATLAM combines composite tape laying, large-scale thermoplastic 3D printing in one printhead

CEAD, GKN Aerospace Deutschland and TU Munich enable additive manufacturing of large composite tools and parts with low CTE and high mechanical properties.

-

Hybrid process marries continuous, discontinuous composites design

9T Labs and Purdue applied Additive Fusion Technology to engineer a performance- and cost-competitive aircraft bin pin bracket made from compression-molded continuous and discontinuous CFRTP.

-

Large-format 3D printing enables toolless, rapid production for AUVs

Dive Technologies started by 3D printing prototypes of its composite autonomous underwater vehicles, but AM became the solution for customizable, toolless production.