Collins Aerospace to invest $225 million in Landing Systems facility expansions in Fort Worth, Spokane, Pueblo

The planned expansions include 115,000 additional square feet of carbon brake manufacturing space between the company’s Washington and Colorado facilities.

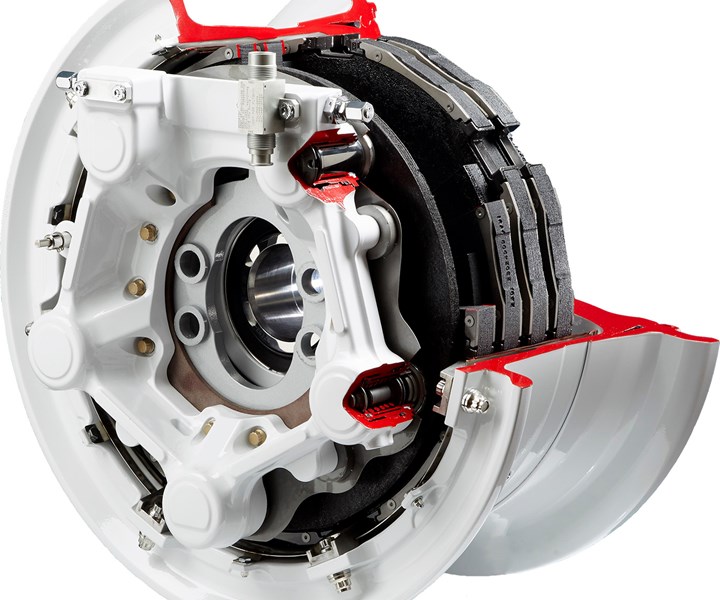

Wheel and brake system. Source | Collins Aerospace

Collins Aerospace Systems (West Palm Beach, Fla., U.S.) a unit of United Technologies Corp., has reported plans to open a new Landing Systems facility in Fort Worth, Texas, and to expand its carbon brake manufacturing facility in Spokane, Washington. An expansion of the company’s carbon brake manufacturing facility in Pueblo, Colorado, is already underway.

The company says its Landing Systems business has grown in recent years due to increasing demand for its wheels, brakes and landing gear from commercial, military and business aviation customers.

Collins Aerospace’s patented DURACARB carbon friction material is reported to deliver an average 35% longer brake life over competing carbon materials, enabling airlines to decrease maintenance time and realize additional cost savings. Read more about carbon/carbon brakes.

In Spokane, Collins Aerospace plans to invest $145 million to expand its existing carbon brake manufacturing facility by more than 50%, adding 75,000 square feet in the form of three new buildings. The expansion is slated to begin in 2021 and result in the creation of 50 new jobs.

The Spokane addition follows an $80 million expansion at Collins Aerospace’s carbon brake manufacturing site in Pueblo, where the company added 40,000 square feet and has hired an additional 50 employees. The Pueblo expansion began in 2015 and is expected to be complete in 2021.

At its new 110,000-square-foot facility in Fort Worth, Collins Aerospace will perform wheel & brake maintenance, repair and overhaul (MRO) operations as well as landing gear assembly. The addition of wheel and brake MRO capacity in Fort Worth will put the company closer to key airline customers in the region. The new facility will also combine the company’s current Fort Worth landing gear operations, while increasing shop floor space 30% over its existing landing gear facility. The company expects to create 40 new jobs at the site.

“As one of the aerospace industry’s leading providers of wheels, brakes and landing gear, we are committed to investing in our business to better serve our customers,” says Ajay Mahajan, vice president, Landing Systems at Collins Aerospace. “Once our projects in Fort Worth, Spokane and Pueblo are complete, we will have invested $225 million, while creating more than 100 new jobs across those communities.”

Related Content

-

Cryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

-

ASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

-

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

.jpg;width=70;height=70;mode=crop)