Commercial-scale carbon fiber recycling comes to Tennessee

Accepting carbon fiber waste materials now, Carbon Fiber Recycling will recycle 2,000 tons of carbon fiber waste per year at its Tennessee facility.

Source, all images | Carbon Fiber Recycling LLC

Carbon Fiber Recycling’s 35,000-square-foot Tazewell, Tenn., U.S. recycling facility is under construction and expected to open in early 2021, but the company reports that it is now accepting carbon fiber waste.

Using a proprietary, continuous-flow pyrolysis process, the facility, which will employ about 20 people, will reportedly have the capacity to recycle at least 2,000 tons of carbon fiber waste per year, producing an unsized chopped or milled carbon fiber product. To accommodate its production rate, the company needs the support of the carbon fiber industry to make this happen. Carbon Fiber Recycling is already working with a few companies that have implemented a green, sustainable approach to carbon fiber waste.

“We’ll take any form of carbon fiber – cured or uncured, thermoset or thermoplastic,” says Tim Spahn, executive director of licensing and sales for Carbon Fiber Recycling LLC.

Specifically, the company is looking for carbon fiber waste, prepreg or finished parts that contain at least 30% carbon fiber. The only exception, Spahn says, is carbon fiber that is mixed with glass fiber, which the company is unable to process.

So far, Spahn says, the company has received its material from companies in the automotive, aerospace and sporting good industries. Companies interested in recycling are asked to send the company a sample and then upon approval, to ship the material to the facility. “In most cases, the truth is that it’s cheaper to recycle [carbon fiber] than it is to landfill it,” Spahn says.

He adds, “In our process, we are able to recycle every part of the waste material we bring in – nothing ends up in a landfill.”

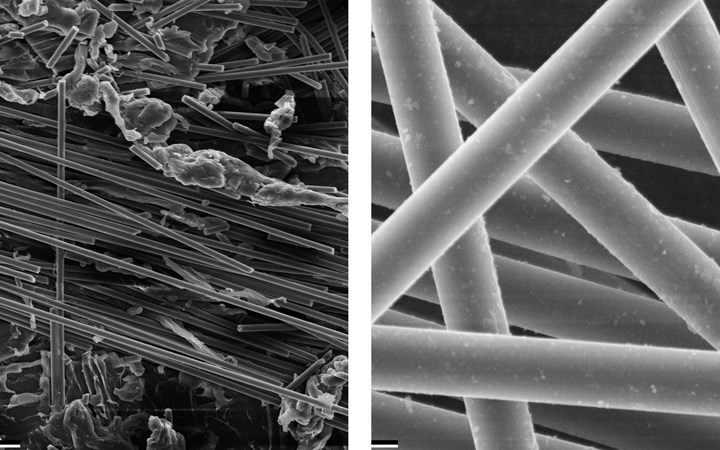

SEM images of carbon fibers before (left) and after (right) recycling.

The company’s chopped fiber product can be used for a variety of applications. For example, Spahn says that Carbon Fiber Recycling is working closely with the Fibers and Composites Manufacturing Facility (FCMF) at the University of Tennessee (Knoxville) and Oak Ridge National Laboratory (ORNL, Oak Ridge, Tenn., U.S.) on new uses and applications for the recycled fiber.

The company is eyeing expansion opportunities throughout the U.S. and European markets once its process becomes proven.

For more information, go to carbonfiberrecycling.com or reach out to Tim Spahn at tspahn@carbonfiberrecycling.com.

Related Content

-

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

-

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

-

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

.jpg;width=70;height=70;mode=crop)