Concordia University leverages Swiftcomp VABS software

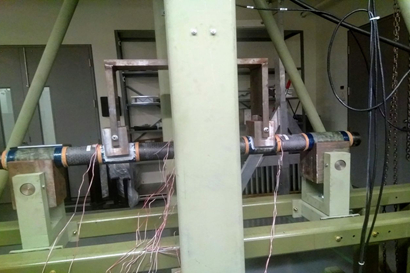

The university is using AnalySwift’s simulation software as part of the company’s Academic Partner Program to research composite tubes, particularly those used in helicopter landing gear.

Photo Credit: Concordia University

AnalySwift, LLC, (West Jordan, Utah, U.S.) announced on Nov. 2 that Concordia University (Montreal, Quebec, Canada) is participating in its recently launched Academic Partner Program (APP), and is using its two products, the VABS and SwiftComp simulation software — which enable highly efficient, yet accurate modeling of composite structures and materials — for researching composite tubes, particularly those used in helicopter landing gear. The research is taking place in the Concordia Centre for Composites (CONCOM), a research group in the Gina Cody School of Engineering and Computer Science at Concordia University.

Led by Professor Suong Van Hoa, CONCOM is reported to have a mission to attain world-class excellence in research, training and industrial development activities in composites, with an emphasis on the research and development of low-cost, high-volume polymer matrix composite structures. CONCOM also carries out research on fundamental work in metal matrix and ceramic matrix composites (CMC).

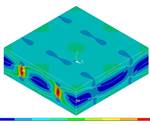

“We are working on analysis of composite tubes, including using the variational asymptotic method (VAM),” says Saeid Khadem Moshir, PhD student at Concordia University in CONCOM. “We are analyzing the bending of thermoplastic composite tubes for the application of landing gear in helicopters. The utilization of a fast and accurate method for analysis of composite tubes made of a large number of layers is necessary. The SwiftComp software is used as an accurate and quick tool for this stress analysis of composite tubes.”

He continues: “These tubes are manufactured by an automatic fiber placement machine [AFP]. Real-life applications for the present research include analyzing stress and bending behavior of cross tubes for landing gear of helicopters.”

According to AnalySwift, its Academic Partner Program (APP) offers participating universities no-cost licenses of engineering software programs VABS and SwiftComp so students, researchers and faculty can leverage the tools in their academic research. It also affords students an additional avenue to highlight their research. A robust community of users helps answer questions through the online cdmHUB (composite design and manufacturing HUB) platform. In October, it was reported that Dalian University joined APP as well.

“We are excited by the work being done by researchers at Concordia University as part of their academic research on helicopter landing gear, and we are pleased they have selected VABS and SwiftComp as part of their toolset,” says Allan Wood, president and CEO of AnalySwift. “As a versatile simulation tools for composites, they save orders of magnitude in computing time without a loss of accuracy so engineers can consider more design options and arrive at the best solution more quickly.”

Related Content

-

AMRC Training Centre introduces composites apprenticeship opportunity

With partners McLaren and Teledyne CML Composites, the Training Center will train new composites technicians in South Yorkshire to build up the future industry workforce.

-

Women in the Composites Industry brings together women for networking, educational opportunities

Aiming to support the growth of women in this industry, the WCI industry group and its partners recently held its first live training event hosted by Owens Corning.

-

Inha University incorporates SwiftComp simulation software to virtually test composites

AnalySwift’s SwiftComp tool aims to mitigate the burden of costly experiments and enable accurate testing of woven and braided composite structures.