Construction of new Arevo composite 3D printing facility announced

The continuous fiber 3D printing specialist also named new executive leadership to support its growth plans.

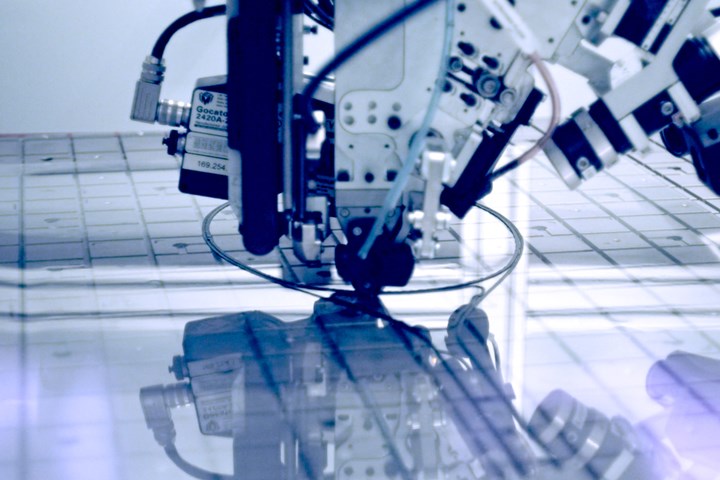

Source | Arevo

Composite 3D printing specialist Arevo (Santa Clara, Calif., U.S.) announced on June 8 that it is constructing a new plant to operate its rapid-turnaround manufacturing-as-a-service (MaaS) model for high-speed continuous carbon fiber-reinforced polymer (CFRP) composite additive manufacturing. Arevo has not yet announced which city the new plant is located in, but says that it will be in Asia.

Arevo’s MaaS program is an on-demand service for the production of custom, 3D-printed composite parts. MaaS represents the second generation of Arevo’s composite material deposition technology, and, the company says, is more than four times faster than the first generation. Arevo says it plans to host hundreds of production systems at the new location, enabling the company to meet customer demand for the rapid turnaround of large and geometrically complex CFRP products.

In November 2019, Arevo announced that it had partnered with AGC Inc. (Tokyo, Japan), which will provide MaaS services using Arevo’s Aqua 3D printer.

In addition, the company has recently brought on new executive staff to support its growth plans. Sonny Vu, CEO, is an entrepreneur who founded wearables company Misfit. Tuan TranPham, chief revenue officer (CRO), is a 17-year veteran of the 3D printing industry and was most recently CRO of Desktop Metal. Daisuke Tanaka, general manager in Japan, is an entrepreneur who previously served as general manager for various Japanese technology companies.

“The new team will be key to our success as we enter into this new expansion phase. We needed people who had a blend of startup experience, ability to scale technical businesses as well as deep industry experience in additive manufacturing,” says Hemant Bheda, Arevo co-founder and chairman.

Related Content

-

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

-

Plant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

-

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

.jpg;width=70;height=70;mode=crop)