Continuous Composites, Siemens Energy apply high-performance materials for power generators

Continuous Fiber 3D Printing (CF3D) enables new designs for AM with thermoset GFRP composite and exceeds material requirements for generator components.

Share

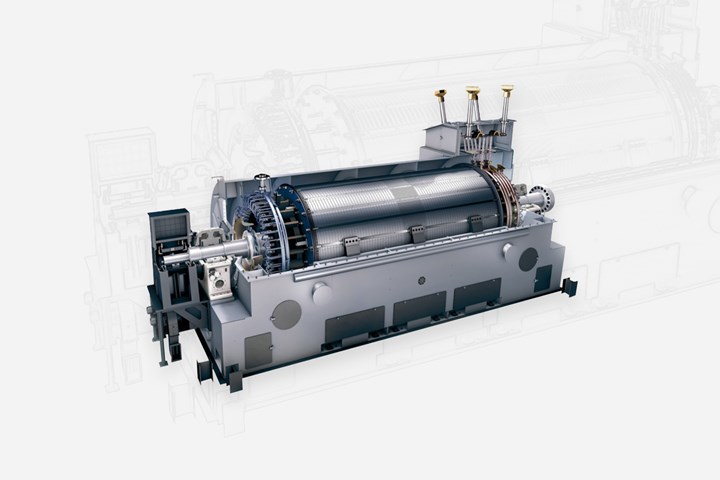

Composite power generator. Photo Credit: Business Wire

Continuous Composites (Coeur d'Alene, Idaho, U.S.) and Siemens Energy (Munich, Germany), a spin-off of the former Gas and Power division of Siemens Group, announced the successful demonstration of Continuous Fiber 3D Printing (CF3D) technology for Siemens Energy’s generator components. Through this multi-year collaboration, the companies developed a thermoset glass fiber-reinforced polymer (GFRP) material, introducing better mechanical performance at higher temperatures, topology optimized designs and dynamic fiber steering to orient anisotropic fibers in the load direction for customized applications.

“The deployment of CF3D for manufacturing generator components is one example where our technology is disrupting current manufacturing processes and replacing metallic parts with high-performance composite materials,” says Tyler Alvarado, CEO of Continuous Composites. “Our collaboration with Siemens Energy demonstrates our ability to develop and customize material solutions with stringent mechanical property requirements which go well beyond the energy sector.”

Continuous Composites and the company’s materials partner, Arkema (Cologne, Germany), through its Sartomer Business, jointly developed a high-temperature CF3D thermoset polymer, enabling the printing of large, complex parts that would not be able to be manufactured using traditional composite techniques. According to Continuous Composites, the material achieved a glass transition temperature (Tg) of 227°C and experienced minimal strength loss at temperatures above the Tg. Further, the CF3D-printed composites reportedly demonstrated fiber volume fractions (FVF) greater than 50% with less than 1.5% void content.

According to Continuous Composites, several generator components are currently manufactured using a metal casting process which is expensive and has long lead times. The development of these new materials paired with the CF3D process, however, is said to exceed the material temperature requirements of generators and other Siemens Energy applications. Demonstration results for the energy sector include manufacturing costs that are five times less than traditional generators and decreased lead time from 8-10 months down to three weeks. Moreover, it is reported that there is $1 million in long-term downtime energy savings and a significant reduction in part weight and material waste.

“The superior mechanical performance of CF3D, combined with the significant cost and lead time reduction, led to our selection of Continuous Composites,” says Dr. Joel Alfano, principal technology development engineer at Siemens Energy. “The opportunity to replace a metallic generator component with composite materials leveraging AM is a powerful breakthrough for solving the constraints we face in the energy industry, and CF3D technology is making it possible.”

Related Content

-

UniSQ fire-retardant resins development bolster bushfire mitigation

The University of Southern Queensland has received funding to be used in the development of cost-effective composite resins to increase the resilience of wind turbine blades against bushfire exposure.

-

Monadnock HTAC Veil protects GFRP equipment against corrosion

Binder-free ECTFE-apertured reinforcement maintains a high resistance against chemicals and abrasion at high temperatures, extending performance and integrity of composite systems.

-

Raw materials distributor provides quality fiberglass, resin variety

CAMX 2024: Imate Composites presents a variety of resins, fiberglass and roving products, as well as mats and catalysts.