Continuous fiber-reinforced thermoplastic composites contributing to electronics sustainability

Life Cycle Assessment (LCA) finds Covestro’s Maezio continuous fiber-reinforced thermoplastic composites can significantly reduce carbon footprint for laptop applications.

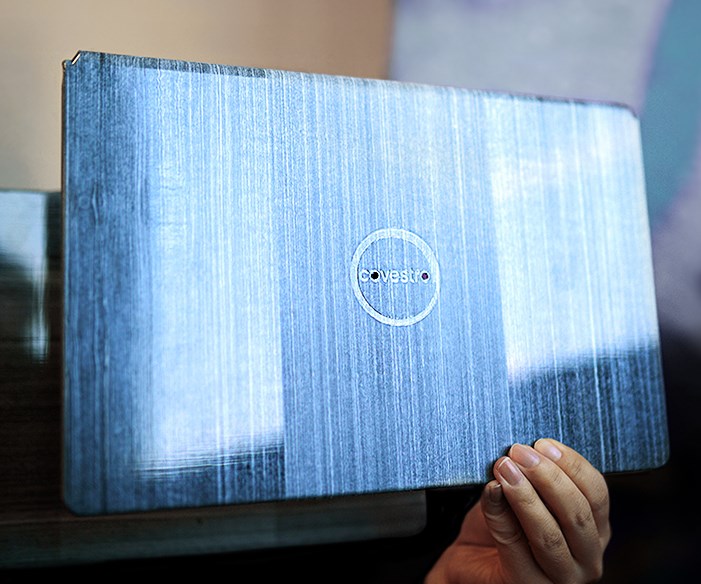

Laptop A-cover made of Maezio continuous fiber-reinforced thermoplastic composites

Source | Covestro

A recent Life Cycle Assessment (LCA) has found a laptop cover made of Covestro’s (Leverkusen, Germany) Maezio continuous fiber-reinforced thermoplastic composites can significantly reduce the carbon footprint by more than 70% compared to one made from conventional aluminum-magnesium alloy.

The LCA study, conducted in line with ISO 14040/14044 standards and reviewed by an independent panel of LCA experts chaired by DEKRA Assurance Service GmbH (Stuttgart, Germany), compared a comprehensive range of parameters to assess the environmental performance of a laptop A-cover made from the two materials which are typically used for premium laptops. In all impact categories and scenarios, the composite laptop A-cover shows better environmental performance than the aluminum-magnesium alloy cover from the extraction of raw materials until the end of life.

Even after the implementation of current technology developments — use of low impact cover gas for aluminum-magnesium alloy and potential benefits of recycling for both materials — the composite carbon footprint is still more than 30% lower.

“Thermoplastic composites are ideally suited for producing thinner, lighter and more robust parts for IT devices that meet the needs of tomorrow,” says Lisa Ketelsen, head of the thermoplastic composites business at Covestro. “The fact that Maezio thermoplastics are not only mechanically competitive but can also be environmentally advantageous will provide the electronics industry and many other industries with a powerful solution for reducing carbon footprint and reaching their sustainability targets.”

Compared to aluminum-magnesium alloys, Maezio composites can also achieve weight reductions of approximately 15%, and the composite A-cover exhibits a similar good bending and torsional rigidity compared to the metallic material. Moreover, the composite A-cover meets the V-0 classification of Underwriters Laboratories’ UL 94 flammability standard.

Previously Covestro received a European Plastics Innovation Award for its composite “A-cover” for next-generation laptops in 2017. The development received the second prize in the “Best Lightweight Innovation” category.

This post is courtesy of the CompositesWorld and AZL Aachen GmbH media partnership.

Related Content

-

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

-

Manufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

-

Developing repairs for thermoplastic composite aerostructures

HyPatchRepair project proves feasibility of automated process chain for welded thermoplastic composite patch repairs.