CSP clip system solution improves assembly, serviceability of EV battery enclosures

CSP and Teijin multi-material EV battery enclosure clips remove the need for multiple fasteners, spread the seal load more evenly, reduce assembly costs.

All photo credit: Continental Structural Plastics

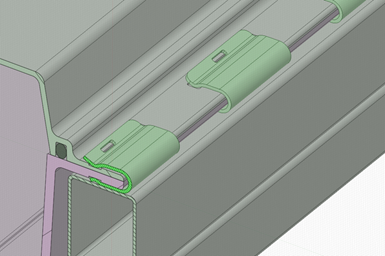

It was reported on Feb. 1 that Continental Structural Plastics (CSP, Auburn Hills, Michigan, U.S.), along with its parent company Teijin Ltd. (Tokoyo, Japan), has introduced a patent-pending clip system that replaces the need for bolts in the process of joining the top and bottom of an electric vehicle battery case. According to CSP, this clip system improves the seal, reduces assembly costs and makes the batteries easier to service when needed. The clips will be manufactured at CSP Stamping in Manchester, Mich, U.S..

Instead of using secondary machined holes and welds to join the top and bottom sections of the box, the steel clips affix to the company’s multi-material battery enclosure via molded-in features. Unlike a point load created by using a bolt, these clips spread the seal load more evenly across the upper and lower flange. On CSP’s multi-material battery enclosure, 68 clips designed to hold 3 PSI of internal pressure replace 72 bolts that would all need to be torqued to a specified value. Each clip provides 950 Newtons of clamp force.

“By using these clips in place of multiple fasteners and different types of welds, we can reduce assembly cost, complexity and the amount of scrap involved in the production of each enclosure,” says Hugh Foran, executive director of CSP’s Advanced Technologies Center. “Our customers come to us with a number of challenges when it comes to developing the most efficient EV battery enclosures. This clip idea is just one example of how we are constantly searching for ways to improve both manufacturing process and the end product.”

In fact, says CSP, these clips are just one of the many innovative features of its full-sized, multi-material battery enclosure consisting of a one-piece composite cover, one-piece composite tray with aluminum and steel reinforcements, and a mounting frame using a structural foam for energy absorption. This enables a reduced frame thickness and weight, while improving crash performance.

By molding the cover and the tray each as one piece, CSP says it has created a system which is easier to seal and can be certified prior to shipment. All told, the CSP multi-material battery enclosure is 15% lighter than a steel battery box. Although it is equal in weight to an aluminum enclosure, the CSP enclosure offers better temperature resistance than aluminum, especially if the company’s phenolic resin system advanced composite is used.

Related Content

-

Envalior offers novel Tepex composite for EV battery housings

Low-thickness, recyclable thermoplastic composite passes strict thermal runaway tests for EV battery housings.

-

SMC composites progress BinC solar electric vehicles

In an interview with one of Aptera’s co-founders, CW sheds light on the inspiration behind the crowd-funded solar electric vehicle, its body in carbon (BinC) and how composite materials are playing a role in its design.

-

SABIC launches fiber-reinforced, intumescent, fire-retardant resins

SABIC PP compound H1090 and Stamax 30YH611 resins are well suited for extruding and thermoforming large, complex EV battery pack components for automotive.