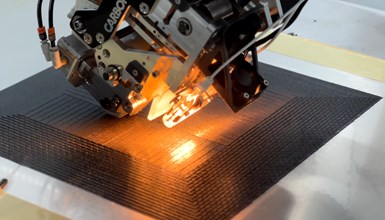

CTC commissions Carbon Axis XCell machine for LaiLa project

The XCell AFP machine is being used to investigate innovative fiber deposition concepts and improve lightweight production via Industry 4.0.

As part of the “Laboratory for intelligent lightweight production” (LaiLa) project, Composite Technology Center/CTC GmbH (Stade, Germany), a subsidiary of Airbus Operations GmbH (Hamburg, Germany), has successfully commissioned a Carbon Axis (La Rochelle, France) XCell automated fiber placement (AFP) machine in collaboration with the Helmut Schmidt University/University of the Federal Armed Forces (HSU, Hamburg, Germany). In use since August 2023, the XCell machine enables the automation of 2D and 3D composites preforms (1 × 0.6 × 0.5 m part size) within an enclosed and temperature-regulated environment that ensures reliable manufacturing in a small footprint and high process repeatability.

The XCell machine will be used to test digital solutions to improve efficiency and robustness of the AFP process in an industry-oriented laboratory environment. The XCell machine is equipped with Industry 4.0 connectivity that enables the collection and analysis of process data that can lead to higher productivity and quality of final parts. In addition, the XCell machine at CTC is integrated with a tape winding system to manufacture revolution and hot air technology parts for the deposition of thermoplastic and dry fiber materials.

“As part of the LaiLa model factory, this XCell machine offers us and our researchers from the HSU an excellent validation platform for developing new digital solutions in the context of fiber deposition technologies for improving industrial robustness, quality, sustainability and economic efficiency in future production systems,” Marc Fette, CEO at CTC, says. “We are proud to use this machine and we are looking forward to a fruitful collaboration with our partner Carbon Axis!”

The LaiLa project is funded by dtec.bw – Digitalization and Technology Research Center of the Bundeswehr, the German Federal Armed Forces. Dtec.bw is funded by the European Union (Next Generation EU).

Learn more about the LaiLa project here and read “Laboratory for Intelligent Lightweight Production at CTC Stade advances digital solutions for industrial composites.”

Related Content

-

Modular, robotic cells enable high-rate RTM using any material format

Airborne’s automated ply placement systems at Airbus, GKN Aerospace and Teijin Automotive Technologies aim to maximize flexibility and intelligent automation.

-

How AI is improving composites operations and factory sustainability

Workforce pain points and various logistical challenges are putting operations resilience and flexibility to the test, but Industry 4.0 advancements could be the key to composites manufacturers’ transformation.

-

Com&Sens presents workshop on fiber optic sensing for COPVs

Three-day hands-on workshop from June 11-13 in Leuven, Belgium, will equip participants with a better understanding of fiber optic sensing technology for digital manufacturing of composite tanks.

.jpg;maxWidth=300;quality=90)