Addcomposites highlights novel composites manufacturing developments

AFP-XS and AddPath updates, new AFP and continuous AM systems, upcoming webinars and blog content are available to interested industry members.

Addcomposites (Espoo, Finland) has announced latest advancements in equipment, software, upcoming webinars and some of its latest blog posts, all designed to elevate composites manufacturing processes automation and innovation.

New technologies and product updates

The company has recently integrated digital twin and in-situ quality control into its AddPath software. This feature is now available to all AFP-XS users, ensuring real-time quality checks and optimizations.

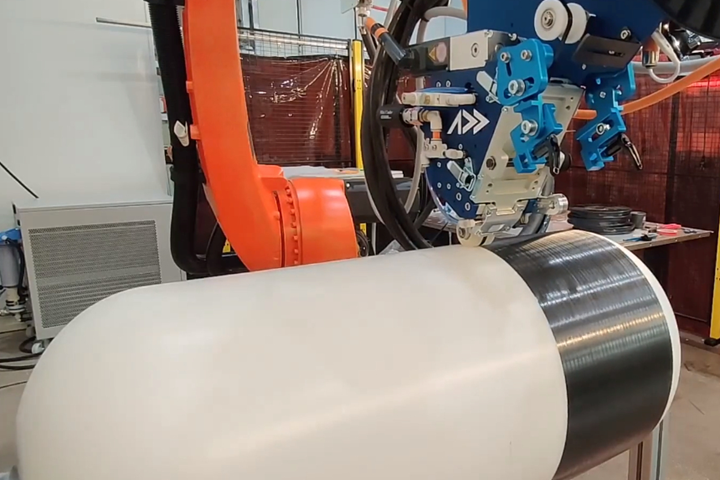

A simple update to AddPath 1.6.0 now enables the automated fiber placement (AFP) system to function as a conventional filament winder. This eliminates the need for a separate winding system, offering a more streamlined and cost-effective solution for composites manufacturers.

Addcomposites unveil its new four-tow AFP-X system, designed to achieve high production rates for intricate parts. The system boasts a material capacity that holds up to 16 times more than the AFP-XS ¼ inch material and is ideal for environments requiring continuous production. It is compatible with both thermoplastic and thermoset materials, offering enhanced productivity. More will be shared at a later date

Responding to growing demand for continuous fiber additive manufacturing, Addcomposites also introduces the SCF3D system, crafted to swiftly produce high-quality structural components with continuous fiber reinforcement. It complements the company’s AFP systems for added localized strength.

Webinars

Addcomposites explores the future of composites manufacturing through its recent webinars, including sessions on “Revolutionizing Filament Winding” and “Efficient Sleeves for Electric Motors using AFP.” These webinars provide invaluable insights into the latest trends and technologies in the field.

An upcoming live demo webinar on Oct. 12, “Mastering Filament Winding with AFP,” will guide users on how to use AFP as a filament winder to produce thermoset- and thermoplastic-wound parts.

Latest blogs on composites

For those looking to dive deeper into the world of composites, Addcomposites also offers a range of articles covering everything from the history of filament winding to the intricacies of AFP.

The company hopes these advancements resonate with ongoing and prospective projects in the field of composites manufacturing. For further information or inquiries, feel free to reach out to Addcomposites.

Related Content

-

Plant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

-

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

-

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.