DLR Institute of Structures and Design increases maturity of thermoplastic composite fuselage structures

Project with Airbus demonstrates OOA co-consolidated stringer-stiffened skin with resistance welded frame and cleats.

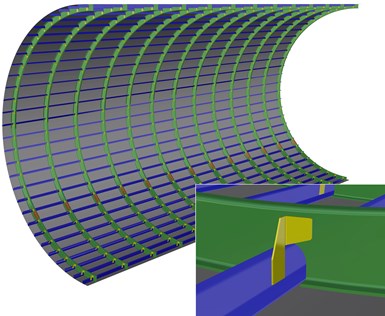

Carbon fiber-reinforced thermoplastic composite demonstrator representing part of a typical fuselage section comprises a skin stiffened by three stringers, a frame segment and three cleats. The stringer-stiffened skin is manufactured in an out-of-autoclave co-consolidation process and resistance welding is used to integrate the frame and cleats. Photo Credit all images: DLR Institute of Structures and Design

As part of the “LuFoV-3 TB-Rumpf” project, the autoclave-free consolidation of thermoplastic prepreg laminates and resistance welding is being further developed and validated as technology bricks for future aircraft fuselages. This work is being carried out by the German Aerospace Center (DLR), Institute of Structures and Design (Institute BT) in Stuttgart, collaborating with partners from the aerospace industry, including Airbus and other research institutes.

DLR Institute BT has demonstrated a fully integrated fuselage intersection, consisting of skin, stringers, frame and cleats. The demonstrator is based on an out-of-autoclave (OOA) consolidated curved skin with co-consolidated stringers and integration of frames and cleats via resistance welding. The welds have been characterized by mechanical tests and the weldline was further examined using an optical microscope.

TB-Rumpf maturing OOA consolidation and welding

State of the art for consolidation of large-area components made of continuous fiber-reinforced high-temperature thermoplastics (e.g., polyaryletherketone or PAEK) is autoclave consolidation. However, through an optimized process setup and tailored process control, it is possible to achieve complete consolidation using only temperature and vacuum pressure. The use of self-heated molds or ovens can eliminate the need for an autoclave and thus generate cost advantages. The TB-Rumpf project aims to mature the process called VCT (Vacuum Consolidation Technique) and to determine the process limits, including maximum possible laminate thickness.

Another key technology for future applications of advanced thermoplastic composites is welding for assembly. DLR and Airbus have identified resistance welding as a leading technology due to its ability to achieve high-strength structures. Within the TB-Rumpf project, the resistance welding process and necessary welding elements are being optimized. The resulting demonstrators are structurally tested to validate the mechanical performance of the joint and the welded composite laminates.

Investigation of vacuum consolidation technique (VCT)

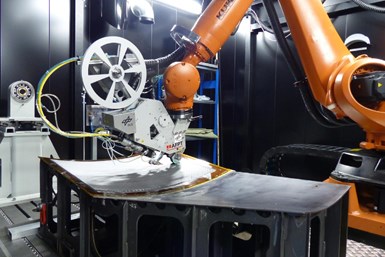

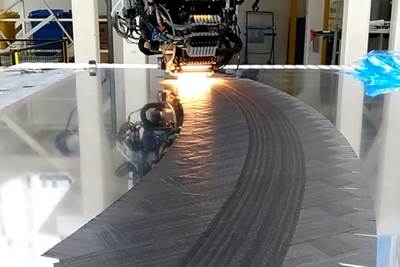

Matthias Horn, project leader at DLR Institute BT, explains that the TB-Rumpf demonstrator uses unidirectional carbon fiber-reinforced low-melt polyaryletherketone (LMPAEK). This thermoplastic composite tape is processed using automated fiber placement (AFP) achieved using a KUKA (Augsburg, Germany) robot with an AFPT (Doerth, Germany) end-effector and 6-kilowatt laser for heating the tape.

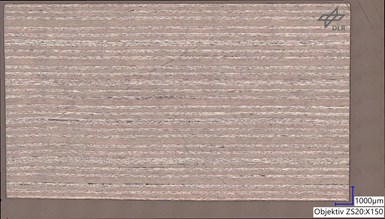

Micrograph cross-section for a high-quality, 11-mm-thick, 60-layer thermoplastic composite laminate manufactured using the VCT out-of autoclave technology.

OOA consolidation using VCT: “The goal was to validate the feasibility of this process for thick laminates,” says Georg Doll, Institute BT researcher and TB-Rumpf lead for consolidation. “We have shown good results for laminates up to 11 millimeters in thickness, without pores or other imperfections, validated by micrograph cross-sections and ultrasonic inspection. The keys to this success are an optimized VCT setup, a tailored heating cycle and homogenous and consistent prepreg quality.”

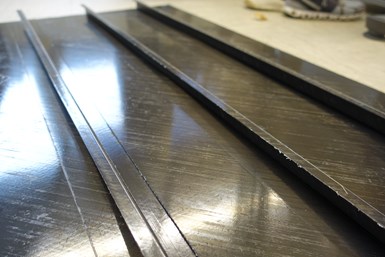

Stringer-stiffened skin (1000 x 600 mm), manufactured with VCT technology and co-consolidated stiffener elements.

OOA co-consolidation of stiffener elements: In addition to using VCT for production of fuselage skin panels without an autoclave, the TB-Rumpf project has also succeeded in developing co-consolidation for direct integration of the stringer stiffener elements with the skin during a single VCT process cycle.

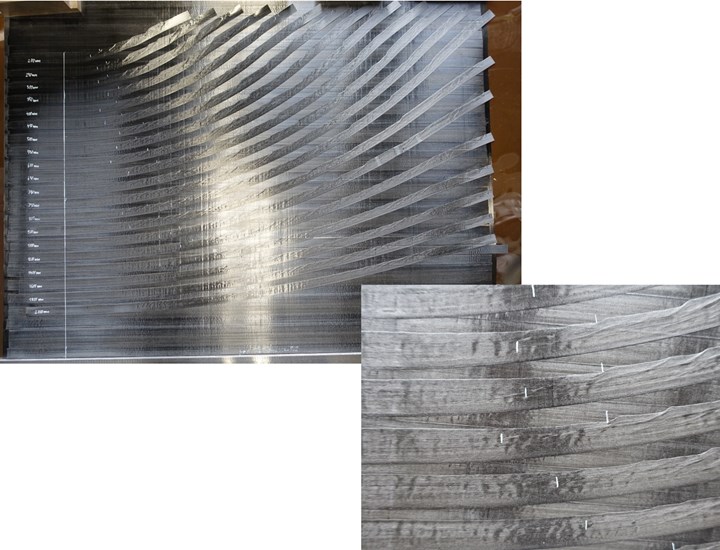

AFP layup of curved and double curved shapes: Laser-based AFP as a complementary process to VCT was investigated, including process and material limits (e.g., maximum tape steering), by manufacturing double-curved laminates measuring roughly 800 x 1200 millimeters. The results from these manufacturing trials can be used to advance OOA consolidation as well as in-situ consolidation, which is achieved during AFP without a secondary operation.

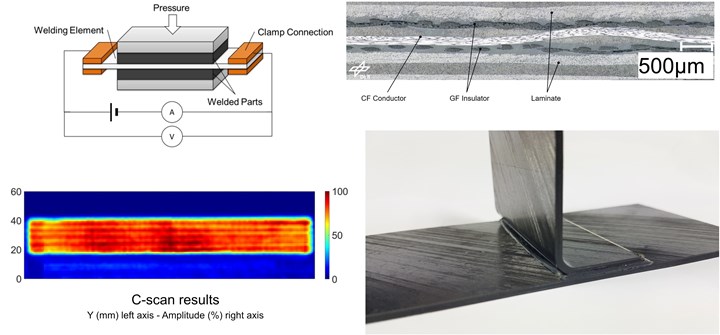

Resistance welding

“To integrate structural fuselage elements, and thus make production of future thermoplastic fuselage concepts feasible, we investigated resistance welding with respect to increased process robustness and optimized strength values,” says Simon Bauer, Institute BT researcher and TB-Rumpf lead for welding. “The focus was on an optimized welding element setup, based on carbon fiber as the heating element, and improved electrical conduction, in combination with the best suitable welding parameters, such as the heating cycle, temperature, pressure, current and voltage.” Resistance welding was used to attach the cleats to both the frame and stringers; it was also used to attach the frame to the skin.

From top left clockwise: diagram of resistance welding setup; micrograph of resistance welded joint zone showing the carbon fabric conductor in the center and surrounded by electrically insulating glass fabrics with layers of the joined laminates at the top and bottom; L-pull specimen for mechanical testing of welded profiles; and C-scan of porosity-free, homogenous welding area.

Technology bricks for upcoming fuselage designs

“Due to the demonstrated technology maturity, both out-of-autoclave consolidation as well as resistance welding can play an important role for future fuselage designs,” underlines Dr. Paul Jörn, head of the corresponding Airbus project.

To bring the technologies even closer to industrial application, further challenging aspects will be investigated in close future. For vacuum consolidation the size scaling and transfer to double curved contours will be focused. For resistance welding tolerance aspects as well as automation aspects will be addressed.

The results presented here were achieved within the TB-Rumpf research project (FKZ: 20W1721D) in the framework of the Federal Aviation Research Program V-3, funded by Germany’s Federal Ministry for Economic Affairs and Energy.

For more information, please visit dlr.de/bt.

Related Content

Jeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

Read MoreTU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreCombining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read MoreRead Next

STUNNING project successfully develops 8.5-meter thermoplastic fuselage skin

Clean Sky 2 project under the MFFD program produces two segments of an 8.5-meter-long, 4-meter-diameter thermoplastic fuselage skin via NLR’s in-house AFP machine, with consolidation plans this summer.

Read MoreWelding thermoplastic composites

Multiple methods advance toward faster robotic welds using new technology for increased volumes and larger aerostructures.

Read MoreAFP tow steering comes of age, Part 1: Current state

It used to be enough that AFP systems could precisely and quickly place and cut multiple tows to build complex aerostructures. Now, fabricators need those tows steered, and the tighter the radius, the better.

Read More