ESA and NASA validate Airbus Earth Return Orbiter design

Airbus and European suppliers prepare for production and assembly of the composites-intensive satellite to meet a 2025 delivery target date and 2026 launch.

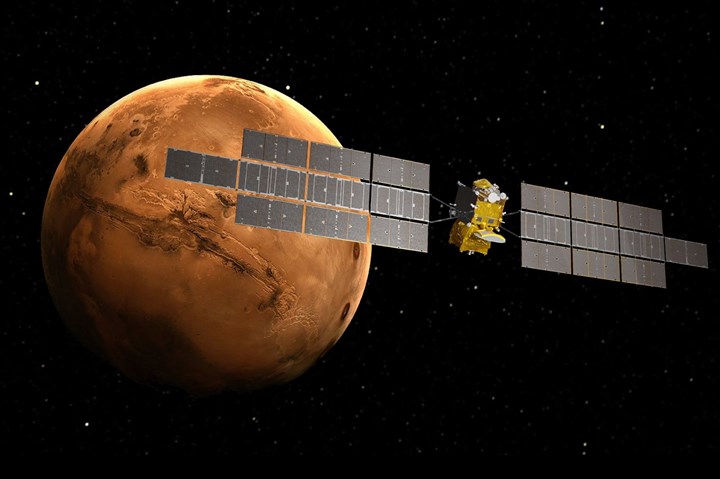

An artist's rendition of the Earth Return Orbiter (ERO). All photo credit: Airbus

On June 15, Airbus (Toulouse, France) reported that the Earth Return Orbiter (ERO) satellite mission has passed preliminary design review (PDR) with the European Space Agency (ESA) and with the participation of NASA. The ERO is the next phase after the successful Perseverence rover launch in February 2021 and the Sample Retrieval Lander mission to bring the first Mars samples back to Earth. It has been confirmed by Airbus that a majority of the ERO’s structure will use composite materials, mainly “sandwiches based on aluminum honeycomb and carbon fiber skins” excepting the radiator panels, heat pipes and pieces that must withstand the highest mechanical forces.

With technical specifications and designs validated, suppliers from eight European countries are on board for nearly all components and sub-assemblies. Development and testing of equipments and sub-systems can now start to ensure the mission moves ahead on schedule.

“This PDR has been managed and closed in a record time of less than a year, an amazing achievement considering the complexity of the mission,” says Andreas Hammer, head of Space Exploration at Airbus. “The entire ERO team, including suppliers and agencies, has really pulled together and we are on target to achieve delivery in 2025 — only five and a half years after being selected as prime contractor.”

The next milestone for the ERO will be the Critical Design Review, Airbus says, which will occur in two years after which production and assembly will start, to secure delivery of the full spacecraft in 2025. After launch in 2026, on an Ariane 64 launcher, the satellite will begin a five year mission to Mars, acting as a communication relay with the surface missions (including Perseverance and Sample Fetch Rovers (SFRs), also to be designed and built by Airbus), performing a rendezvous with the orbiting samples and bringing them safely back to Earth.

The seven-ton, seven-meter-high ERO spacecraft, equipped with 144-square-meter solar arrays with a span of more than 40 meters — which Airbus claims is the the largest ever built — will take about a year to reach Mars. It will use a mass-efficient hybrid propulsion system combining electric propulsion for the cruise and spiral down phases and chemical propulsion for Mars orbit insertion. Upon arrival, it will provide communications coverage for the NASA Perseverance rover and Sample Retrieval Lander (SRL) missions, two essential parts of the Mars Sample Return campaign.

For the second part of its mission, ERO will have to detect, rendezvous with and capture a basketball-size object called the Orbiting Sample (OS), which houses the sample tubes collected by the SFR. Once captured, the OS will be bio-sealed in a secondary containment system and placed inside the Earth Entry Vehicle (EEV), a third containment system to ensure that the samples reach the Earth’s surface intact.

It will then take another year for ERO to make its way back to Earth, where it will send the EEV on a precision trajectory towards a pre-defined landing site, before itself entering into a stable orbit around the sun.

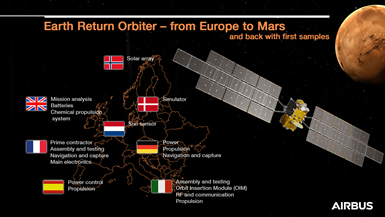

Airbus says it has overall responsibility for the ERO mission, developing the spacecraft in Toulouse, France and conducting mission analysis in Stevenage, U.K.. Aerospace manufacturer Thales Alenia Space (Cannes, France) will also have an important role, assembling the spacecraft, developing the communication system and providing the Orbit Insertion Module from its plant in Turin, Italy. Airbus says other suppliers come from Germany, France, the U.K., Italy, Spain, Norway, Denmark and the Netherlands.

Airbus says the record development and design for ERO has only been possible because of the company’s decision to build on already mature and proven technologies, instead of developing brand new technologies which risked associated delays. Proven Airbus technologies include decades of experience in plasma (electric) propulsion, acquired through station keeping and in orbit operations of full electric telecom satellites, as well as its expertise on large solar arrays (telecoms and exploration missions, including JUICE, said to be the biggest solar panels for an interplanetary mission until ERO) and complex planetary missions like BepiColombo, launched in 2018.

Airbus will also leverage its vision-based navigation technological lead (RemoveDEBRIS, Automatic Air to Air refueling), and autonomous navigation expertise (Rosalind Franklin and SFRs) and rendezvous and docking expertise built up over decades, using technologies from the successful ATV (Automated Transfer Vehicle) and recent developments from JUICE, Europe’s first mission to Jupiter.

Related Content

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreCryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreRead Next

NASA Ingenuity Mars helicopter prepares for first flight

The composites-intensive helicopter is to make the first attempt at powered, controlled flight of an aircraft on another planet, with the goal of hovering 3 meters above the Martian surface.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More

.jpg;maxWidth=300;quality=90)