NASA Ingenuity Mars helicopter prepares for first flight

The composites-intensive helicopter is to make the first attempt at powered, controlled flight of an aircraft on another planet, with the goal of hovering 3 meters above the Martian surface.

An illustration of NASA’s Ingenuity Helicopter flying on Mars. Photo Credit: NASA/JPL-Caltec

NASA reported on March 23 that it is targeting no earlier than April 8 for the Mars helicopter, Ingenuity, to make the first attempt at powered, controlled flight of an aircraft on another planet. Before the 4-pound (1.8-kilogram) rotorcraft can attempt its first flight, however, both it and its team must meet a series of daunting milestones.

Ingenuity currently remains attached to the belly of NASA’s Perseverance rover, which touched down on Mars Feb. 18. On March 21, the rover deployed the guitar case-shaped graphite composite debris shield that protected Ingenuity during landing. The rover currently is in transit to the “airfield” where the helicopter will attempt to fly. Once deployed, Ingenuity will have 30 Martian days, or sols, (31 Earth days) to conduct its test flight campaign.

“When NASA’s Sojourner rover landed on Mars in 1997, it proved that roving the Red Planet was possible and completely redefined our approach to how we explore Mars. Similarly, we want to learn about the potential Ingenuity has for the future of science research,” says Lori Glaze, director of the Planetary Science Division at NASA headquarters. “Aptly named, Ingenuity is a technology demonstration that aims to be the first powered flight on another world and, if successful, could further expand our horizons and broaden the scope of what is possible with Mars exploration.”

Flying in a controlled manner on Mars is far more difficult than flying on Earth, NASA says. The Red Planet has significant gravity (about one-third that of Earth’s) but its atmosphere is just 1% as dense as Earth’s at the surface. During Martian daytime, the planet’s surface receives only about half the amount of solar energy that reaches Earth during its daytime, and nighttime temperatures can drop as low as -130F (-90C) which can freeze and crack unprotected electrical components.

To fit within the available accommodations provided by the Perseverance rover, the Ingenuity helicopter must be small. To fly in the Mars environment, it must be lightweight. To survive the frigid Martian nights, it must have enough energy to power internal heaters. The system — from the performance of its rotors ( constructed from carbon fiber and foam core) in rarified air to its solar panels, electrical heaters and other components — has been tested and retested in the vacuum chambers and test labs of NASA’s Jet Propulsion Laboratory in Southern California.

“Every step we have taken since this journey began six years ago has been uncharted territory in the history of aircraft,” says Bob Balaram, Mars Helicopter chief engineer at JPL. “And while getting deployed to the surface will be a big challenge, surviving that first night on Mars alone, without the rover protecting it and keeping it powered, will be an even bigger one.”

Deploying the helicopter

However, before Ingenuity takes its first flight on Mars, it must be squarely in the middle of its airfield — a 33 x 33-foot (10 x 10-meter) patch of Martian real estate chosen for its flatness and lack of obstructions. Once the helicopter and rover teams confirm that Perseverance is situated exactly where they want it to be inside the airfield, the elaborate process to deploy the helicopter on the surface of Mars begins.

“As with everything with the helicopter, this type of deployment has never been done before,” says Farah Alibay, Mars Helicopter integration lead for the Perseverance rover. “Once we start the deployment there is no turning back. All activities are closely coordinated, irreversible and dependent on each other. If there is even a hint that something isn’t going as expected, we may decide to hold off for a sol or more until we have a better idea what is going on.”

The helicopter deployment process will take about six sols (six days, four hours on Earth). On the first sol, the team on Earth will activate a bolt-breaking device, releasing a locking mechanism that helped hold the helicopter firmly against the rover’s belly during launch and Mars landing. The following sol, they will fire a cable-cutting pyrotechnic device, enabling the mechanized arm that holds Ingenuity to begin rotating the helicopter out of its horizontal position. This is also when the rotorcraft will extend two of its four landing legs.

During the third sol of the deployment sequence, a small electric motor will finish rotating Ingenuity until it latches, bringing the helicopter completely vertical. During the fourth sol, the final two landing legs will snap into position. On each of those four sols, the Wide Angle Topographic Sensor for Operations and eNgineering (WATSON) imager will take confirmation shots of Ingenuity as it incrementally unfolds into its flight configuration. In its final position, the helicopter will hang suspended at about 5 inches (13 centimeters) over the Martian surface. At that point, only a single bolt and a couple dozen tiny electrical contacts will connect the helicopter to Perseverance. On the fifth sol of deployment, the team will use the final opportunity to use Perseverance as a power source and charge Ingenuity’s six battery cells.

“Once we cut the cord with Perseverance and drop those final 5 inches to the surface, we want to have our big friend drive away as quickly as possible so we can get the sun’s rays on our solar panel and begin recharging our batteries,” says Balaram.

On the sixth and final scheduled sol of this deployment phase, the team will need to confirm three things: that Ingenuity’s four legs are firmly on the surface of Jezero Crater, that the rover did, indeed, drive about 16 feet (about 5 meters) away, and that both helicopter and rover are communicating via their onboard radios. This milestone also initiates the 30-sol clock during which time all preflight checks and flight tests must take place.

“Ingenuity is an experimental engineering flight test — we want to see if we can fly at Mars,” says MiMi Aung, project manager for Ingenuity Mars Helicopter at JPL (Pasadena, California). “There are no science instruments onboard and no goals to obtain scientific information. We are confident that all the engineering data we want to obtain both on the surface of Mars and aloft can be done within this 30-sol window.”

As with deployment, the helicopter and rover teams will approach the upcoming flight test methodically. If the team misses or has questions about an important preflight milestone, they may take one or more sols to better understand the issue. If the helicopter survives the first night of the sequence period on the surface of Mars, however, the team will spend the next several sols doing everything possible to ensure a successful flight, including wiggling the rotor blades and verifying the performance of the inertial measurement unit, as well as testing the entire rotor system during a spin-up to 2,537 rpm (while Ingenuity’s landing gear remain firmly on the surface).

The first flight test on Mars

Once the team is ready to attempt the first flight, Perseverance will receive and relay to Ingenuity the final flight instructions from JPL mission controllers. Several factors will determine the precise time for the flight, including modeling of local wind patterns plus measurements taken by the Mars Environmental Dynamics Analyzer (MEDA) aboard Perseverance. Ingenuity will run its rotors to 2,537 rpm and, if all final self-checks look good, lift off. After climbing at a rate of about 3 feet per second (1 meter per second), the helicopter will hover at 10 feet (3 meters) above the surface for up to 30 seconds. Then, the Mars Helicopter will descend and touch back down on the Martian surface.

Several hours after the first flight has occurred, Perseverance will downlink Ingenuity’s first set of engineering data and, possibly, images and video from the rover’s Navigation Cameras and Mastcam-Z. From the data downlinked that first evening after the flight, the Mars Helicopter team expect to be able to determine if their first attempt to fly at Mars was a success.

On the following sol, all the remaining engineering data collected during the flight, as well as some low-resolution black-and-white imagery from the helicopter’s own Navigation Camera, could be downlinked to JPL. The third sol of this phase, the two images taken by the helicopter’s high-resolution color camera should arrive. The Mars Helicopter team will use all information available to determine when and how to move forward with their next test.

“Mars is hard,” says Aung. “Our plan is to work whatever the Red Planet throws at us the very same way we handled every challenge we’ve faced over the past six years — together, with tenacity and a lot of hard work, and a little Ingenuity.”

Related Content

Welding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreA new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

Read MoreRead Next

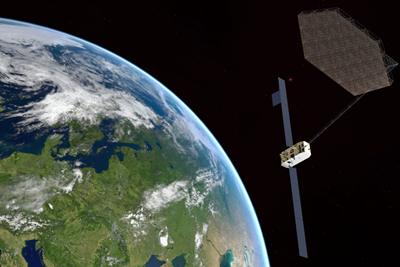

Airbus PERIOD project to pioneer satellite factory in space

PERIOD consortium to prepare concept for in-orbit demonstrator for satellite assembly and manufacturing in space, with potential for composite materials.

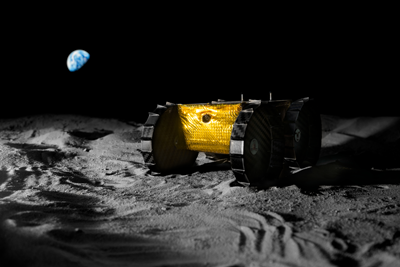

Read MoreComposites design helps nano-sized lunar rover hit big milestones

Developed by Carnegie Mellon University, the ultralight, composites-intensive Iris nano-rover will make its lunar debut later this year.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More